Roberts Loom facts for kids

The Roberts loom was a special machine invented by Richard Roberts in 1830. It was made from strong cast iron. This loom was the first power loom that worked better and was more reliable than weaving by hand. It was also easy to adjust. Because of this, it became very popular in the cotton factories of Lancashire, England.

Contents

Who Was Richard Roberts?

Richard Roberts was born in Llanymynech, a village on the border of England and Wales. His father, William Roberts, was a shoemaker and also managed a tollgate. Richard learned from the local priest.

He later worked with a boatman on the Ellesmere Canal. He also worked in local limestone quarries. A road surveyor named Robert Bough taught him some drawing skills. Bough worked for the famous engineer Thomas Telford.

Roberts became known for making very precise machine tools. He worked from his workshop in Manchester. There, he focused on making textile machines better. In 1822, he received a patent for his cast-iron loom. Then, in 1830, he patented the self-acting mule. These inventions completely changed how both spinning (making yarn) and weaving (making cloth) were done.

How the Roberts Loom Worked

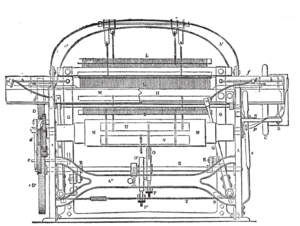

The Roberts loom, patented in 1822, was improved in 1830. Its frame was made of strong cast iron. It had two side frames, each cast in one piece. Three crossbars connected these frames very precisely. A large arched bar at the top held the healds, which are parts that help move the threads.

Moving the Yarn

The yarn, called warp, came from a large roll called the warp beam. It passed over a roller and went horizontally through the loom. Then it turned vertically to another roll, the cloth beam. Keeping the yarn tight was very important. If the tension changed, threads could break.

Roberts had a clever way to keep the tension even. As the warp beam emptied, it got smaller. To keep the tension, he added a wooden pulley to the beam. Ropes wrapped around this pulley were attached to weights. This created friction, slowing the beam down and keeping the yarn tight. The cloth beam had a special wheel that helped pull the finished cloth. This was one of Roberts's key inventions.

The Heddles and Power

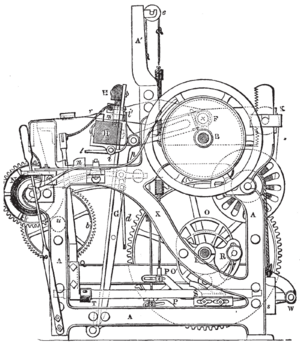

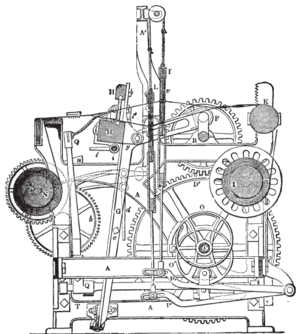

The loom used standard heddles. These are wires or cords with loops that lift and lower threads. They were arranged in groups of four. This made sure that nearby threads did not rub against each other. The bottom of the heddles connected to foot pedals, called treadles. These treadles were pushed down by special cams, which are like spinning wheels with an uneven shape.

A leather belt connected the loom to a steam engine. This belt turned a main shaft. This shaft had a flywheel to make the motion smooth. It also had a crank that moved the battens (parts that push the weft thread into place). Another toothed wheel on this shaft turned a second shaft, called the tappet shaft. This tappet shaft was very important. It lowered the treadles and threw the shuttle. The tappet shaft turned half as fast as the main shaft.

Throwing the Shuttle

The shuttle, which carries the weft thread across the warp, was thrown by two levers. These levers were activated by a roller on the tappet shaft. When the shuttle reached the end of its path, it hit a lever. This lever acted as a brake. If the shuttle did not hit this lever, it meant something was wrong, and the loom would stop automatically. This was a safety feature.

Impact on Industry

The Roberts loom came out when the power loom industry was growing fast. Before this, hand looms were much more common than power looms. The reliable Roberts loom was quickly adopted by factories. This created a new problem: there wasn't enough spun yarn to keep up with the fast weaving.

Richard Roberts then solved this problem by creating the self-acting (automatic) spinning mule. Because of these inventions, making textiles was no longer a skilled craft. Instead, it became an industrial process. This process could be done by workers who were not highly skilled. For example, spinning yarn became a job for men, while weaving became a job for women and girls.

| Year | 1803 | 1820 | 1829 | 1833 |

|---|---|---|---|---|

| Looms | 2,400 | 14,650 | 55,500 | 100,000 |

| Calvin Brent |

| Walter T. Bailey |

| Martha Cassell Thompson |

| Alberta Jeannette Cassell |