Screw-cutting lathe facts for kids

A screw-cutting lathe is a special machine that helps make very accurate screw threads. Think of a screw thread as the spiral groove on a screw that helps it grip things. This machine works by carefully moving a cutting tool in a straight line while the metal piece (called the workpiece) spins. The movement of the tool is precisely matched to the spinning of the metal. This way, the machine can create the perfect spiral shape needed for a screw.

The name "screw-cutting lathe" is mostly used to talk about older machines. Many centuries ago, lathes couldn't make screws. Later, from the Late Middle Ages until the early 1800s, some special lathes were called "screw-cutting lathes" because they had this ability. Today, most metalworking lathes can cut screws, but we just call them "lathes" because it's a common feature.

Contents

How Screw-Cutting Lathes Work

A screw-cutting lathe uses a special part called a leadscrew. This leadscrew is connected to the main spinning part of the lathe (the spindle) with gears. By changing these gears, the machine can make different types of screw threads. For example, it can make threads that are fine or coarse, or threads that are designed for different measurement systems (like English or metric). Every tiny turn of the metal piece is matched by a specific small movement of the cutting tool. This makes sure the screw thread is always perfect.

The History of Screw-Cutting Lathes

Screws have been around for thousands of years. Ancient people like Archimedes described how to use a screw to lift water. Screws used as fasteners (like the ones in your furniture) date back to before the time of Christ. Even though screws were very useful, they were hard to make. This made them expensive and not widely used. The goal of screw-cutting lathes was to solve this problem. They aimed to make screws cheaply and easily, which was very important as the world started to industrialize.

Early Wooden Screws

The first screws were usually made of wood. People carved them by hand, sometimes using a simple lathe with hand tools like chisels. They tried to make them as accurate as possible. Sometimes, they even used tree branches that had vines wrapped around them in a spiral shape as a guide. This natural spiral might have given them ideas for how to make screws.

Early Metal Screws

Early metal screws were also made by hand. Workers used files to cut the threads. One way to make a fairly accurate thread was to scratch a line on a metal rod using a knife. The knife would be angled just right to create the correct spiral. This was one method used by early inventors like Henry Maudslay to make the leadscrews for his machines. Making screws this way was slow and costly, and the quality depended a lot on the worker's skill. People needed a way to make screws automatically and more accurately.

First Lathes with Guided Tools

Lathes have existed since ancient times. It seemed obvious to use them to cut screws, but figuring out how to guide the cutting tool precisely was a challenge for many centuries. Big breakthroughs happened in the late Middle Ages and early modern period. One of the earliest known examples is from the 15th century, shown in a book called the Mittelalterliche Hausbuch. This machine had parts that held the tool steady (called slide rests) and a leadscrew to guide it. Around the same time, Leonardo da Vinci drew sketches of different screw-cutting machines, some with two leadscrews and even changeable gears.

Over the next three centuries, many other designs appeared, especially for people who made fancy decorative items or clocks. These designs had clever ideas, but most were not very accurate or practical for everyday use.

Henry Hindley built a screw-cutting lathe around 1739. His machine used a plate to guide the tool and was powered by a hand crank with gears. By changing the gears, he could cut screws with different pitches (how far apart the threads are). He could even make left-handed threads by removing a gear.

Modern Screw-Cutting Lathes (Late 1700s to Early 1800s)

The first truly modern screw-cutting lathe was probably built by Jesse Ramsden in 1775. His machine had a leadscrew, a slide rest, and a change gear system. These three parts are still found in modern lathes today (except for computer-controlled ones). Ramsden used his new lathe to make even more accurate lathes. With these, he created very precise tools for astronomy, surveying, and navigation in the 18th century.

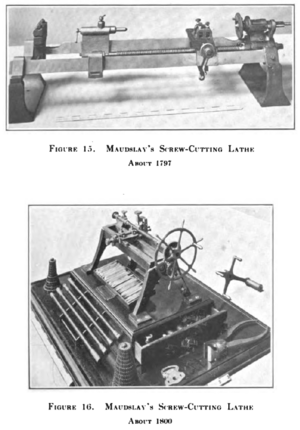

Other inventors followed. A French mechanic named Senot made a screw-cutting lathe in 1795 that could be used for industrial production. David Wilkinson of Rhode Island used a slide rest in 1798. However, these inventors were soon outshined by Henry Maudslay. In 1800, Maudslay created what many consider the first screw-cutting lathe that was truly practical for factories. His lathe had a leadscrew that was geared to the main spindle. This made the tool move at a steady speed, ensuring very accurate screw threads.

Bryan Donkin improved Maudslay's design in 1826. He added a way to fix small errors in the leadscrew itself. Joseph Whitworth, who learned from Maudslay, created a design that became a standard for many British railway companies. This standard, called British Standard Whitworth (BSW), was the world's first national screw thread standard. These machines were also sent to Europe and the United States. They allowed factories to make large numbers of screws that were interchangeable (meaning any screw of a certain type would fit). This led to the standardization of screw threads across companies and eventually internationally.

Screw-Cutting Lathes Today

Until the early 1800s, there was a clear difference between a "screw-cutting lathe" and a "plain lathe." A plain lathe couldn't guide the cutting tool precisely enough to make accurate threads. But since the early 1800s, most general-purpose metalworking lathes have included the parts needed for screw-cutting. So, we don't usually call them "screw-cutting lathes" anymore.

Today, screws for things like machines, wood, or drywall are usually not made by single-point screw-cutting. Instead, they are made by faster methods like thread forming and rolling or using special tools called die heads. These faster methods are used in modern screw machines. While these machines are designed to make screws, they don't use the old single-point screw-cutting method.

See also

- Lathe

- Lathe (metal)

- Screw machine

| Emma Amos |

| Edward Mitchell Bannister |

| Larry D. Alexander |

| Ernie Barnes |