Air lock diving-bell plant facts for kids

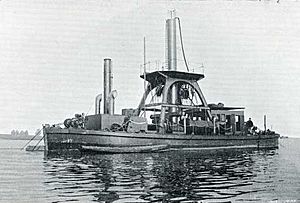

The air lock diving-bell plant was a unique barge used in Gibraltar Harbour. Its main job was to help lay, check, and fix the huge moorings (anchoring systems) for battleships. This special vessel was designed by Siebe Gorman & Company and Forrestt & Co. Ltd. It was built and delivered to the British Admiralty in 1902.

Gibraltar's harbour has a very hard, rocky seabed. This made it difficult to set anchors in the usual way, which is by burying them in soft mud or sand. So, a special tool was needed to dig into the rock. This barge was the perfect solution! It allowed workers to dig holes on the seabed, even in normal clothes, thanks to its clever design. In 1969, the Gibraltar Chronicle newspaper said this plant was still working and might have been the only one of its kind in the world!

Contents

What Was This Special Barge?

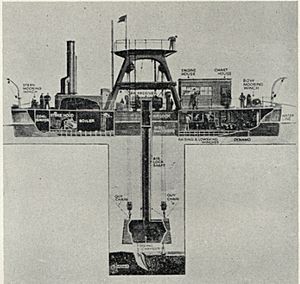

This unique steel barge weighed 346 tons. It was about 26 meters (85 feet) long and 11.7 meters (38 feet, 6 inches) wide. It had a special air lock diving-bell system, a decompression chamber, and other safety gear.

The Diving Bell's Design

The diving bell itself was like a large, open-bottomed room. It was 4.5 meters (15 feet) long, 3.2 meters (10 feet, 6 inches) wide, and 2.3 meters (7 feet, 6 inches) high. A central tube, 11.4 meters (37 feet, 6 inches) tall and 0.9 meters (3 feet) wide, allowed workers to enter.

The bell was made of steel plates and heavy cast-iron. It weighed about 46 tons! Inside, it had electric lights and a telephone to talk to the people on the barge above. It even had a special drill to break rocks underwater. This diving bell was like a mobile underwater workspace, and the barge was its launchpad.

How Did the Bell Work?

The bell was lowered and raised using strong wire ropes that ran over pulleys. These pulleys were on a large frame built over a well (an opening) in the middle of the barge's hull. Two sets of air compressors were on the deck. One set pumped air into the bell, keeping the water out. The other set powered the rock drill. The bell could work at depths up to 12 meters (40 feet). It usually worked at a pressure of about 15 pounds per square inch (psi), which is like being about 10.6 meters (35 feet) underwater.

Building the Barge

The British Admiralty ordered this vessel for His Majesty's Dockyard in early 1902. It was designed by Siebe Gorman and Forrestt & Co. Ltd, who also built it. Forrestt & Co. Ltd was a very old company, started in 1788, known for building special ships and naval equipment.

The barge was tested on the River Colne before September 1902. It was said that fish were very curious about the bell, swimming around it because of the light inside! Once finished, the diving-bell barge was towed directly from Wivenhoe to Gibraltar. The whole project, including the barge, cost the Admiralty about £14,000. An image of this plant was even in a famous 1909 Diving Manual by Sir Robert Davis.

How the Barge Was Used

The main job of the plant was to bury the three anchors for each battleship mooring deep into the seabed.

First, a separate mooring vessel, like HMS Moorland in the 1960s, would place the mooring parts in the right spot. Then, the diving-bell barge would be towed over the work area. It had no engine of its own, so tugboats moved it around. Once in place, the barge would use six or eight anchors to stay perfectly still. It could make small adjustments by pulling on these anchors with winches.

Working Underwater

The access tube on the bell was sealed at the top. The bell was then lowered through the opening in the barge's hull (the moon pool) down to the seabed. Air was pumped into the bell, pushing the water out. This created an air-filled space inside the bell where workers could stand directly on the seabed.

Workers would climb down into the entry tube, go through an airlock, and then down a ladder into the working chamber. Once the anchor's spot was marked, a winch on the barge would lift the anchor. The barge would then move the anchor aside. After that, the barge would return to its original spot. Four men inside the bell would then start digging a hole for the anchor.

Working in the damp, dim, pressurized conditions, the men would first clear away any mud. Then, they would use pickaxes to break the rock. As the hole got deeper, one man would hold a crowbar while another swung a sledgehammer. The broken rock pieces were passed up by hand out of the hole. Digging a hole big enough for an anchor could take two or three days.

Once the anchors were buried, the mooring vessel would finish setting up the rest of the mooring system. The completed moorings, marked with buoys, would then stay in place permanently.

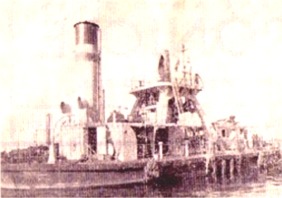

The Barge in the 1960s

At some point, the barge got a new boiler, a bigger cabin, and a new, larger funnel. As mentioned earlier, in 1969, the Gibraltar Chronicle reported that the plant was still working and was thought to be the only one of its kind. This system was even used in the late 1960s to help set up moorings for the Mr. Louie oil rig when it visited the Bay.

HMS Moorland

HMS Moorland was a mooring vessel built in 1938 on the Clyde. She first worked at Scapa and later on the Clyde and Rosyth. In 1961, she moved to Gibraltar. Her story ended on January 26, 1971, when she was sunk as target practice for HMS Juno in the western Mediterranean. Moorland had two powerful 10-ton winches for lifting heavy items from the seabed. She also carried all the cables and anchors needed for laying moorings. Her crew included a Master, two engineers, and ten ratings. When on mooring duty, she also had a supervisor and twelve deckhands.

| Kyle Baker |

| Joseph Yoakum |

| Laura Wheeler Waring |

| Henry Ossawa Tanner |