Convair B-36 Peacemaker facts for kids

class="infobox " style="float: right; clear: right; width: 315px; border-spacing: 2px; text-align: left; font-size: 90%;" ! colspan="2" style="text-align: center; font-size: large; padding-bottom: 0.3em;" | B-36 "Peacemaker" |-

|- | colspan="2" style="text-align: center;" |  |- |colspan="2" style="border-bottom: 1px solid #aaa;text-align:center;" |The B-36D used both piston and jet engines. |-

|- |colspan="2" style="border-bottom: 1px solid #aaa;text-align:center;" |The B-36D used both piston and jet engines. |-

! Role | Strategic bomber |- ! National origin | United States |- ! Manufacturer | Convair |-

! First flight | 8 August 1946 |-

! Introduction | 1949 |- ! Retired | 12 February 1959 |-

! Primary user | United States Air Force |- ! Produced | 1946–1954 |- ! Number built | 384 |-

! Unit cost | US$4.1 million (B-36D) |-

! Variants | Convair XC-99

Convair NB-36H

Convair X-6 |- ! Developed into | Convair YB-60 |- |}

The Convair B-36 "Peacemaker" was a huge strategic bomber aircraft built by Convair. The United States Air Force (USAF) used it from 1949 to 1959. It was the largest airplane ever built that used piston engines. It also had the longest wingspan of any combat aircraft, stretching 230 feet (70.1 meters).

The B-36 was special because it was the first bomber that could carry any of the U.S. nuclear weapons inside its four bomb bays without needing changes. It could fly 10,000 miles (16,000 km) without stopping to refuel and carry a heavy load of 87,200 pounds (39,550 kg). This made it capable of flying across continents.

When it started service in 1948, the B-36 was the main plane for carrying nuclear weapons for the Strategic Air Command (SAC). Later, the jet-powered Boeing B-52 Stratofortress replaced it starting in 1955. Almost all B-36s were later taken apart for scrap. The B-36 set the standard for how far and how much future U.S. long-range bombers could carry.

Contents

How the B-36 Bomber Was Developed

The idea for the B-36 started in 1941, before the United States joined World War II. At that time, it looked like Britain might be defeated by Germany. This would make it impossible for the U.S. to bomb Germany from bases in Europe. So, the United States Army Air Corps (USAAC) needed a new type of bomber. This bomber had to be able to fly from North America to Europe and back. This meant it needed a very long combat range, at least 5,700 miles (9,200 km).

The USAAC first asked for a bomber that could fly very fast and high. But these requests were too difficult for the technology of the time. So, in August 1941, they changed the requirements. The new bomber needed a maximum range of 10,000 miles (16,000 km). It also needed to carry 10,000 pounds (4,500 kg) of bombs and fly at a cruising speed of 240 to 300 mph (390 to 480 km/h). It also had to fly at 40,000 feet (12,000 m), which was higher than most German anti-aircraft guns could reach.

World War II and the Cold War Era

As the war in the Pacific continued, the air force needed a bomber that could reach Japan from bases in Hawaii. So, the development of the B-36 became very important again. In July 1943, the USAAF ordered 100 B-36s, even before the first test planes were finished. The first B-36 was shown on August 20, 1945, and it flew for the first time on August 8, 1946.

After the United States Air Force was created in 1947, the Cold War began. The Soviet Union tested its first atomic bomb in 1949. American military leaders needed bombers that could carry the very large and heavy first atomic bombs. The B-36 was the only American aircraft that could fly far enough and carry such heavy bombs from U.S. airfields to targets in the Soviet Union.

Even though the B-36 used piston engines and newer jet fighters were appearing, it was still very important. Other jet bombers like the Boeing B-47 Stratojet couldn't fly far enough without refueling. Also, they couldn't carry the huge first hydrogen bombs. So, until the Boeing B-52 Stratofortress started flying in 1955, the B-36 was the main plane for carrying nuclear weapons for the Strategic Air Command.

The B-36 was called the "aluminum overcast" because it was so big. It gave the U.S. the ability to reach targets anywhere in the world. Even though it was slow and couldn't refuel in the air, it could fly missions 3,400 miles (5,500 km) away and stay in the air for up to 40 hours. The B-36 could also fly very high, thanks to its huge wings and six powerful engines. This put it out of reach of most enemy fighter planes and ground-based anti-aircraft guns at the time.

Test Planes and Early Designs

Consolidated Vultee Aircraft Corporation (later Convair) won the competition to build this new bomber in 1941. They planned to build two test bombers. The project faced many delays. When the U.S. entered World War II, Convair was told to slow down B-36 development and build more Consolidated B-24 Liberator planes.

One big problem was the landing gear. The first design used huge single wheels that were 9 feet (2.7 m) tall. These wheels put too much pressure on runways, so the B-36 could only land at a few air bases. The Air Force then asked Convair to design a four-wheel system for each main landing gear. This spread the weight better and made the plane lighter.

B-36 Design Features

The B-36 was an incredibly large aircraft. It was two-thirds longer than the previous "superbomber," the B-29. Its wingspan and tail height were even bigger than the Soviet Union's Antonov An-22, which was the largest propeller-driven plane ever built. Only much later planes like the Boeing 747 and the Lockheed C-5 Galaxy could carry heavier loads.

The B-36's wings were huge, even compared to today's planes. They were 7.5 feet (2.3 m) thick at their thickest part, so big that crew members could crawl inside them to reach the engines. These large wings allowed the B-36 to carry enough fuel for its long missions. They also helped the plane fly at very high altitudes, often above 40,000 feet (12,000 m). This meant it could fly higher than most enemy fighter planes and anti-aircraft guns of the 1940s. Some B-36s could even cruise at 50,000 feet (15,000 m) or higher.

Unique Engine System

The B-36 had a very unusual engine setup. It had six 28-cylinder Pratt & Whitney R-4360 'Wasp Major' radial engines. These engines were mounted in a "pusher configuration," meaning the propellers were at the back of the wings, pushing the plane forward. This was different from most large bombers that had propellers at the front, pulling the plane. Each engine powered a 19-foot (5.8 m) propeller, which was one of the largest ever used on a piston-engined aircraft. This design helped with airflow over the wing but could sometimes cause the engines to overheat.

Adding Jet Power

Starting with the B-36D model, Convair added four General Electric J47-19 jet engines. These were placed in two pods, one near the end of each wing. This meant the B-36 had 10 engines in total: six piston engines and four jet engines. This led to the famous saying, "six turnin' and four burnin'." The B-36 had more engines than any other mass-produced aircraft. The jet engines greatly improved takeoff power and gave the plane a burst of speed when needed, like over a target. During normal flight, the jet engines were turned off to save fuel.

The Crew and Inside the Plane

The B-36 usually had a crew of 15 people. The front part of the plane where the pilots sat was connected to the back part by a pressurized tunnel. This tunnel went through the bomb bay. Crew members could move through the tunnel on a small wheeled cart. The back part of the plane had six beds and a dining area.

Landing Gear Changes

The first test B-36 (XB-36) had huge single wheels for its main landing gear. These tires were 9 feet 2 inches (2.79 m) tall and weighed 1,320 pounds (600 kg). They were so big that they could only be used at a few airfields. Because of this, the single wheels were soon replaced with a four-wheel system for each main landing gear, which spread the weight better.

Weapons Carried by the B-36

The B-36 had four bomb bays that could carry up to 86,000 pounds (39,000 kg) of bombs. This was more than 10 times the amount carried by the World War II B-17 bomber. Even though the B-36 was not designed for nuclear weapons at first (because they were top secret), it became the main plane for carrying them. It was the only plane that could carry the first Mark-17 hydrogen bomb, which was 25 feet (7.6 m) long and weighed 42,000 pounds (19,000 kg). To carry this huge bomb, two bomb bays had to be combined.

For defense, the B-36 had six remote-controlled gun turrets that could be pulled back into the plane. It also had fixed guns in the tail and nose. Each turret had two 20 mm cannons, for a total of 16 guns. However, the shaking from firing these guns often caused problems with the plane's electrical systems.

The first B-36 test plane flew in August 1946. A second test plane, the YB-36, flew in December 1947. This one had a new cockpit design with better visibility and more powerful engines. The first 21 B-36A planes were delivered in 1948. These were used for training. Later, the B-36B model was delivered, which met all the original requirements. However, it had problems with engine reliability and maintenance.

Later models of the B-36 had more powerful engines, better radar, and improved crew areas. The addition of jet engines increased fuel use. In 1954, the Air Force started a "Featherweight" program to make the B-36 lighter. This involved removing the defensive gun turrets and other non-essential equipment. This reduced the crew size from 15 to 9 and allowed the plane to fly farther and higher, especially for reconnaissance (spy) missions. The last B-36 models had only a single radar-aimed tail turret and extra fuel tanks. Production of the B-36 stopped in 1954.

B-36 in Service

The B-36 served in the United States Air Force as part of the Strategic Air Command from 1948 to 1959. Special versions of the B-36, called RB-36s, were used for reconnaissance (spy missions) during the Cold War against the Soviet Union. The bomber versions of the B-36 were used for training and test flights. They were always ready for action, but they were never used to drop bombs in actual combat.

By 1955, the newer, faster Boeing B-52 Stratofortress jet bombers were joining the Air Force in large numbers. This led to the B-36 being replaced.

The main reasons the B-36 became old-fashioned were:

- It was not designed to refuel in the air. This meant it needed to land at intermediate bases to reach targets deep inside the Soviet Union.

- Its slow speed made it easy for Soviet jet fighter planes to attack. This made long-range bombing flights over Soviet territory very dangerous.

The B-36 planes began to be scrapped in February 1956. As B-52s replaced them, the B-36s were flown to Davis-Monthan AFB in Arizona to be taken apart. By December 1958, only 22 B-36s were still in service.

On February 12, 1959, the very last B-36J built flew its final mission from Biggs Army Airfield in Texas to Greater Southwest International Airport in Fort Worth, where it was put on display. Within two years, all B-36s, except five that were saved for museums, had been scrapped.

Images for kids

-

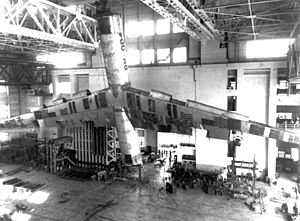

A Convair XC-99 being delivered to Kelly Field in Texas in 1949.

-

B-36J AF Serial Number 52-2217 on display at the Strategic Air Command & Aerospace Museum.

-

B-36J AF Serial Number 52-2220 on display at the National Museum of the United States Air Force.

-

B-36J AF Serial Number 52-2827 on display at the Pima Air & Space Museum.

-

RB-36H AF Serial Number 51-13730 on display at the Castle Air Museum.

See also

In Spanish: Convair B-36 para niños

In Spanish: Convair B-36 para niños