Bowling Iron Works facts for kids

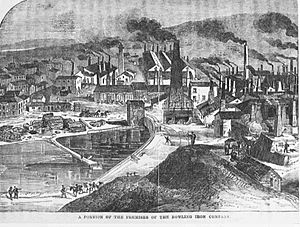

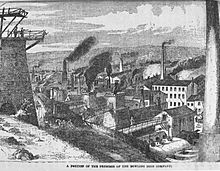

A part of the works in 1861

|

|

| Built | 1784 |

|---|---|

| Location | Bowling, Yorkshire, England |

| Coordinates | 53°47′02″N 1°43′41″W / 53.783901°N 1.728078°W |

| Industry | Ironworking |

| Products | Domestic and industrial iron products |

| Defunct | 1921 |

The Bowling Iron Works was a large factory complex that made iron products. It was started around 1780 in an area called East Bowling, which is now part of Bradford in Yorkshire, England. This huge operation did everything from digging up coal and iron ore to melting the metal, shaping it, and making finished products.

Contents

Finding Iron and Coal

People might have worked with iron near Bradford even in Roman times. Monks from Rievaulx Abbey were making iron in 1150. Later, in 1358, records mention people who worked with forges.

Coal was dug from the ground as early as 1360. The Bowling Ironworks started in the 1780s to use the ironstone and coal found right under their site. The ironstone here had about 32% iron. The coal from the "Better Bed" was special because it had no sulfur. This made it perfect for the hot furnaces used to melt and shape iron. Another type of coal, "Black Bed," was closer to the surface. It could be sold or used for other things like powering boilers.

The company first mined on land owned by Jeremiah Rawson. As they used up the minerals, they bought rights to mine on other nearby lands. In 1794, they bought rights to 90 acres of coal and iron from Sir Francis Wood, who owned Bowling Hall. They bought more rights from him in 1806. Over the years, they kept buying more land and mineral rights. By 1821, they even bought the title of "Lord of the Manor" from Sir Francis.

Other iron companies, like the Low Moor Iron Company (started in 1788) and the Bierley Iron Company (around 1810), also used the same valuable ironstone and coal layers.

How it All Started

The first factory building, called a foundry, was set up in Bowling around 1784. It was started by a group of business people. These included John Sturges, who already owned an ironworks in Wakefield, and Richard Paley, who sold iron in Leeds.

At first, iron was brought to the Bowling foundry from Wakefield. The early products were things for homes, like laundry irons, ovens, and weights for clocks. The part of the factory that melted iron, called the smelting plant, was built in 1788. It made "pig iron," which is raw iron. This pig iron was used to make boiler plates for the first steam engine at the Low Moor works. Even in 1792, they were still sending pig iron to Wakefield and getting finished iron back.

In 1804, more partners joined the company. These included George Paley and John Green Paley, who were related to Richard Paley.

The Story of Bowling Ironworks

The Bowling works sold many guns, cannonballs, and shells to the British government even before 1790. Early guns were made from cast iron. They had to be made very carefully and tested well.

In 1796, the company made a deal with famous inventors Matthew Boulton and James Watt. They agreed to pay a fee for using two steam engines. They also got permission to build more steam engines themselves, as long as they paid the fee.

Later, when William Armstrong invented guns made from wrought iron, some of the first iron he used came from Bowling. "Bowling iron" became famous worldwide for its high quality. People even called it "Best Yorkshire" iron.

The Bowling Ironworks also used special machines called Steam hammers. These hammers used steam power to hit and shape hot metal. A man named John Charles Pearce designed some of these steam hammers. His design was special because the steam engine was right behind the hammer, making the machine shorter.

In 1848, the company became a new partnership called Bowling Iron Co. It officially became a registered company in 1870.

In 1891, someone described the ironworks as being in a deep valley. The sides of the valley were made of waste materials from a hundred years of mining. The whole area was surrounded by a tall stone wall. At night, with glowing ash and bright lights from the furnaces, it looked like a strange, wild place, almost like an active volcano.

At that time, the factory had blast furnaces and other machines for making iron. It had tall chimneys, a shed for the steam hammers, and workshops for making steel and other metal parts. A small railway moved materials around inside the works. A bigger railway line connected the factory to the Great Northern Railway to ship out products. There were also special tracks called tramways that brought minerals from the mines to the factory. Wagons on these tracks were pulled by ropes powered by engines. Big pumps kept the mines from flooding, and some of this water was used in the ironworks.

The Bowling Iron Company faced problems and went out of business in 1898. It was restarted in 1903 as The Bowling Iron Company but finally closed down in 1921.

Life at the Ironworks

By 1840, Bradford was known for having some of the smokiest air in Britain. Laws were made as early as 1803 to make factory chimneys tall enough so they wouldn't cause too much smoke. However, these laws were not often followed. Many people felt that factories provided jobs, so they shouldn't be forced too hard to reduce pollution.

One report from 1841 said that the air in Bradford was very bad because of the ironworks. The Bowling Iron Company was fined in 1874 for causing pollution, but the fine was quite small. People in the area suffered from many breathing problems.

The way workers were paid sometimes caused problems. The manager of the Bowling Works, H. Hartopp, said that miners would send one person to collect everyone's pay. This person would often go to a pub to divide the money, which could lead to problems. The company tried to provide better places for workers to get paid.

The company also spent £5,000 to build St. John's Church in Bowling. The church was finished in 1842. It was special because it was one of the first churches in England built with iron and stone, with only the roof beams made of wood.

In 1847, a school built by the Bowling Iron Company was visited. The company had built the school building but didn't pay much for its running costs. About 150 children went to the school, but only a few were factory workers. The schoolroom didn't have good light or fresh air.

In the mines, young boys called "hurrier-boys" had very hard jobs. They would drag small carts along tracks to the miners. Then, they would drag the full carts back to the mine shaft. There, the carts would be hooked to a chain to be pulled up to the surface.

An investigation into child labor in 1843 mentioned a 15-year-old worker at the Bowling Iron Works. He said the work was "very hard" and that he was "very ill tired." A report in 1847 noted that it was tempting to hire boys younger than the legal age, which was ten years old at the time. Managers sometimes felt that boys needed to start very young to work in the narrow coal seams.

Working in the mines and ironworks was dangerous. In 1875, there was an explosion in the company's Crosses Pit mine. Four workers were killed, and others were hurt. It seemed to be an accident involving gunpowder used to break up large pieces of rock.

A committee heard in 1877 that in West Yorkshire, including Bowling Iron Works, miners often hired boys as their helpers instead of the company hiring them directly. At that time, Bowling employed about 2,000 workers in its mines. About two men died each year in the mines. However, accident rates were even higher in the ironworks, even though fewer people worked there. Boys also worked in the ironworks, doing jobs like pushing hot lumps of iron to the hammers.

Images for kids