Cold blast facts for kids

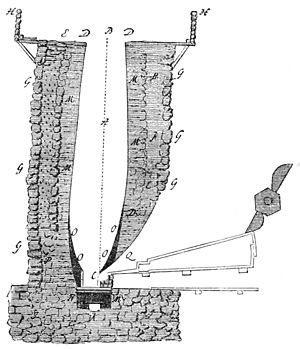

Cold blast is a term from the early days of making iron. It describes a type of furnace where air is blown in without being heated first. This was the original way iron was made for a very long time.

For many years, people thought that using cold air was better. They believed it helped make high-quality iron. This was especially true in winter, when the air was colder and had less moisture. Less moisture in the air was thought to be good for the iron-making process.

The Discovery of Hot Blast

Around 1825, a man named James Beaumont Neilson made a big discovery. He found that using hot air, known as hot blast, was actually much better. Blowing hot air into the furnace made the process more efficient. It also helped make iron faster and cheaper.

Cold Blast Fades Away

Neilson's discovery quickly changed how iron was made. In Great Britain, most ironworks switched to hot blast by 1835. The old cold blast method became outdated very quickly.

Cold blast furnaces lasted a bit longer in the United States. However, hot blast technology was introduced there in 1836. It was especially useful for making iron with anthracite coal. As more and more coke (another type of fuel) was produced in the US, cold blast furnaces slowly disappeared.

One of the very last cold blast furnaces was called Pleasant Furnace (it used to be called Eagle Furnace). This furnace, which used charcoal as fuel, was in Curtin, Pennsylvania. It finally closed down in 1921, marking the end of an era for cold blast ironmaking.

| Anna J. Cooper |

| Mary McLeod Bethune |

| Lillie Mae Bradford |