Hot blast facts for kids

Hot blast is a clever way to make iron in a blast furnace much more efficiently. It means heating up the air before blowing it into the furnace. This simple idea was one of the most important inventions during the Industrial Revolution. It helped save a lot of fuel and made furnaces work better.

Before hot blast, cold air was blown into the furnace. But heating the air first made the furnace much hotter. This meant it could melt more iron and use less coal.

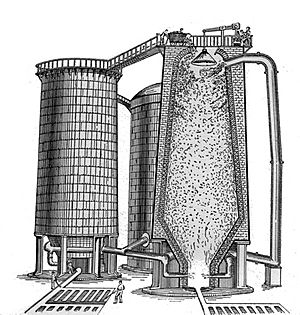

The hot blast method works by using a special container filled with bricks. This container gets very hot from the waste gases of the furnace. Then, fresh air is blown through the hot bricks, heating it up before it goes into the furnace. This process is called regenerative heating.

The hot blast was invented and patented for iron furnaces by James Beaumont Neilson in 1828. This happened at the Wilsontown Ironworks in Scotland. Later, this idea was used in other ways too. For example, the carbon monoxide gas from the furnace could be burned to create even more heat for the air.

Contents

How Hot Blast Changed Ironmaking

The Big Idea and How It Spread

James Beaumont Neilson, who used to work at a gas factory in Glasgow, came up with the hot blast system. He discovered that if he heated the air going into the furnace to about 300 degrees Fahrenheit, he could use much less coal. For every ton of iron made, the amount of coal needed dropped a lot. Even higher temperatures saved even more fuel!

Neilson and his business partners, including Charles Macintosh, got a patent for this invention in 1828. At first, the heating container was made of wrought iron, but it rusted. So, they switched to a cast iron container instead.

Another person, Thomas Botfield, also claimed to have invented the hot blast in January 1828. However, Neilson won the legal battles over the patent. Neilson and his partners had to go to court many times to protect their invention from others who tried to use it without permission.

The hot blast technology didn't spread super fast across Britain. By 1840, 58 iron companies had paid to use Neilson's invention. This brought in about £30,000 a year in fees. When the patent ran out, 80 companies had licenses. By 1843, just after the patent expired, 42 out of 80 furnaces in south Staffordshire were using hot blast. Its adoption was even slower in south Wales.

More Benefits of Hot Blast

The hot blast had other great advantages:

- It allowed ironmakers to use raw coal instead of coke. Coke was more expensive to make.

- In Scotland, they could now profitably melt a lower-quality iron ore called "black band" ironstone.

- It also made furnaces produce more iron each day. For example, at the Calder ironworks, daily output went from 5.6 tons in 1828 to 8.2 tons in 1833. This made Scotland the cheapest place to make steel in Britain during the 1830s.

Early hot blast stoves had some problems. The pipes could break because of heating up and cooling down. This was partly fixed by putting the pipes on rollers. They also had to find new ways to connect the air pipes to the furnace, as leather could no longer be used because of the heat.

Later, the idea of regenerative heating was used even more effectively in things like the Cowper stove. These stoves use waste heat from the furnace to preheat the air. This is still used in modern blast furnaces today. The idea was also used in the open hearth furnace for making steel.

Interestingly, George Crane and David Thomas in Wales came up with the same idea on their own. Crane got a British patent in 1836. They started making iron with their new process in February 1837. Thomas later moved to the US and started the Lehigh Crane Iron Company to use the process there.

Using Anthracite Coal

Hot blast also made it possible to use anthracite coal for making iron. Anthracite is a hard, shiny coal. Before hot blast, it was very hard to light and use in furnaces.

At the time, good coking coal was mostly found in Great Britain and western Germany. So, iron furnaces in the US often used charcoal. This meant that each furnace needed huge areas of forest to make charcoal. When the nearby trees were cut down, the furnace would often stop working.

In 1831, Dr. Frederick W. Gessenhainer got a US patent for using hot blast with anthracite to make iron. He made a small amount of anthracite iron in Pennsylvania in 1836. But he couldn't develop it into a large-scale process because of equipment problems and his illness.

After the American Civil War, coke became more popular than anthracite in the US. Coke was more porous, meaning it had tiny holes, which helped it support the heavy loads inside the much larger furnaces built in the late 1800s.

Images for kids

| Roy Wilkins |

| John Lewis |

| Linda Carol Brown |