Cooroy Lower Mill Site Kiln facts for kids

Quick facts for kids Cooroy Lower Mill Site Kiln |

|

|---|---|

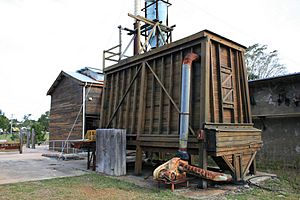

Cooroy Lower Mill Site Kiln, 2009

|

|

| Location | Lower Mill Road, Cooroy, Shire of Noosa, Queensland, Australia |

| Built | 1950s |

| Official name: Cooroy Lower Mill Site Kiln | |

| Type | state heritage (built) |

| Designated | 11 December 2008 |

| Reference no. | 602688 |

| Significant period | 1950s |

| Significant components | chimney/chimney stack, machinery/plant/equipment - forestry/timber industry, drying kiln, boiler room/boiler house |

| Lua error in Module:Location_map at line 420: attempt to index field 'wikibase' (a nil value). | |

The Cooroy Lower Mill Site Kiln is a special old building in Cooroy, Queensland, Australia. It's a type of oven called a kiln that was used to dry timber. It was built in the 1950s and is now protected as a heritage site. This means it's an important part of history that needs to be looked after. It was added to the Queensland Heritage Register on December 11, 2008.

Contents

The Story of the Cooroy Timber Kiln

The Cooroy Lower Mill Site Kiln was built in late 1956. It was made by two well-known timber companies, J Wilkinson and Sons Pty Ltd and Straker and Sons Pty Ltd. This kiln was used to dry timber in the Sunshine Coast area.

In the mid-1900s, South Queensland was a huge timber producer. Timber was one of the most important jobs in the Sunshine Coast region during the 1950s. Even in the 1980s, a large timber mill near Cooroy was said to be the biggest in Queensland.

After World War II, timber companies started to become bigger and join together. This helped them save money and buy new technology, like drying kilns. Better roads also made it easier to bring timber from further away to these larger mills.

By 1956, Straker and Sons and J Wilkinson and Sons already owned several timber mills. They decided to work together and formed a new company called Kiln Dried Timbers Pty Ltd. This new company ran the kiln and a nearby planing mill (which is no longer there). The kiln helped them dry timber much faster. This was important for making things like flooring and special timber boards. It also allowed them to sell timber to places like Sydney and Melbourne, which needed very dry wood. People said this kiln was the first of its kind on the North Coast.

The kiln built in 1956 used steam to dry the timber. It had four large concrete rooms, each about 19.5 meters long and 4 meters high. Workers would carefully stack timber onto trolleys and roll them into the kiln rooms. A large boiler, which was powered by wood waste from the mill, made steam. This steam heated tubes inside the kiln rooms. Electric fans then blew the hot air around to dry the timber. The temperature inside the kiln could reach about 49 degrees Celsius.

The boiler also powered a steam engine and an electric generator. This generator made electricity for the fans and other machines.

Next to the main drying kiln, there was also a special room called a reconditioning chamber. This room was used to fix timber that had shrunk too much. The timber would be steamed in this chamber for about six hours to make it normal again.

In the 1970s, the timber industry became more difficult. So, Strakers and Wilkinsons joined with another timber company, the Lutton family's operation. Together, they formed North Coast Sawmills Pty Ltd. This new company opened an even bigger timber mill.

Later, in the 1980s, Quintex bought the Cooroy mills, and then Boral Timber took over. Boral continued to use the kiln to make and dry timber for flooring and decking. The kiln finally closed in the early 2000s because of new rules about forests. By 2007, the kiln and the old sawmill area were being turned into a public park or community area.

What the Kiln Looks Like Today

The old drying kiln complex is in an open grassy area in Cooroy. It's surrounded by newer industrial buildings. You can still see the boiler shed with its tall chimney, the control room, the reconditioning chamber, and the four-room drying kiln. All the old equipment, like the steam engine and electric generators, are still there too.

The Drying Kiln

The drying kiln is a concrete building with a flat roof. It has four separate rooms, each about 19.5 meters long and 4 meters high. The rooms are open at one end, and you can get into them from a control room at the other end. Inside, there are tracks for the trolleys that carried the timber. Fans and pipes are on the ceilings.

The Reconditioning Chamber

This is a hollow concrete channel next to the drying kiln. It also has tracks for trolleys inside. It was used to fix timber that had shrunk too much.

The Control Room

The control room is a narrow hallway between the boiler shed and the kiln. It has a sloping roof made of wavy metal sheets. Inside, you can see pipes, valves, and gauges. These were used to control how the kiln chambers worked. Each room has a small window and a door from the control room.

The Boiler Shed

The boiler shed is a tall, rectangular timber building with a pointed roof made of wavy metal sheets. A very large boiler sits on a concrete floor inside. A chute fed wood waste from a hopper into the boiler. A tall chimney goes up from the boiler through the roof. You can still see metal ladders on the chimney.

Inside the boiler shed, there are also old electric generators. They have plates that say they were made by the English Electric Company Ltd in London.

Next to the boiler shed, there's a tall timber frame that used to hold a water tank, but the tank is gone now.

The Hopper

The hopper is a rectangular box that gets narrower at the bottom. It's made of timber. It has two fiberglass exhaust ducts on its flat roof. A timber chute runs from the bottom of the hopper into the boiler shed.

Near the kiln site, you can still see parts of the old sawmill, like trolleys, rails, and concrete blocks. This area is now used as an open space for timber work and is not part of the heritage listing.

Why the Kiln is Important

The Cooroy Lower Mill Site Kiln is important for several reasons:

- It shows how Queensland's history changed: This kiln, built in 1956, is a rare example of a timber drying kiln in the Sunshine Coast area. This region was once one of the biggest timber producers in Queensland. It shows how the timber industry started using more scientific and efficient ways to dry wood. It also shows how timber companies began to join together to afford expensive equipment like this kiln. The kiln helped them dry timber faster and sell it to more places.

- It's a rare and special part of Queensland's history: This kiln is the only known timber drying kiln in the Sunshine Coast region that is still mostly complete. Many sawmills used to be in this area, but most of them are gone now. So, finding an intact kiln like this is very uncommon.

- It's a great example of its kind: The kiln is a very complete example of a steam-heated drying kiln with internal fans. This design was once common in the timber industry. All the parts that made it work are still there, including the fuel system, boiler, steam engine, electric generator, heating tubes, fans, and the reconditioning chamber.

- It looks amazing: The tall, rusty chimney of the boiler makes the kiln complex stand out. It looks like an impressive old industrial ruin. The concrete kiln rooms, the rusted metal, and the weathered timber all create a powerful and interesting look.

| James B. Knighten |

| Azellia White |

| Willa Brown |