Creusot steam hammer facts for kids

The Creusot steam hammer is a huge machine built in 1877 in Le Creusot, a town in France. It was made by a company called Schneider and Co.. This amazing hammer could hit with a force of up to 100 tons! For a long time, it was the most powerful hammer in the world.

In 1891, a company in the United States called Bethlehem Iron Company built an even bigger hammer. It was almost the same design but could hit with 125 tons of force. This made the Creusot hammer no longer the most powerful.

Today, the Creusot hammer doesn't work anymore. It is a popular tourist attraction in Le Creusot. Since many other giant hammers have been taken down, the Creusot hammer is now once again the largest of its kind still existing in the world.

In 1981, the American Society of Mechanical Engineers recognized the Creusot steam hammer as a Historic Mechanical Engineering Landmark. This means it's an important machine in history.

Contents

How the Giant Hammer Began

In 1836, two brothers, Joseph Eugène Schneider and Adolphe Schneider, bought an old iron factory. It was in a region called Burgundy, near Le Creusot. They started their company, Schneider Brothers & Co.

Just two years later, their company built the first steam locomotive in France. Eugène Schneider and his main engineer, François Bourdon, then created the world's first real steam hammer in 1841.

Schneider and Co. built many steam hammers over the years. Between 1843 and 1867, they made 110 hammers of different sizes. As their work became harder, they needed bigger and bigger hammers. This led them to plan a truly enormous hammer.

The Creusot steam hammer was finished in 1877. Its ability to hit with 100 tons of force was a new record. Before this, a German company called Krupp had the most powerful hammer, "Fritz," which hit with 50 tons. To celebrate this amazing achievement, a life-sized wooden model of the Creusot hammer was shown at the Paris Universal Exposition in 1878.

What the Hammer Looked Like

The Creusot hammer had four main parts. These were the foundation with the anvil, the legs, the steam cylinder with its parts, and the heavy hitting part itself. This hitting part included the piston, piston rod, hammerhead, and die.

The anvil, which is the base that the hammer hits, weighed a huge 750 tons. To hold this weight and the powerful blows, the machine's base was made of strong stone. It went down 11 meters into the ground to rest on solid rock. On top of the stone, there was a one-meter thick layer of oak wood. This wood provided a soft base for the giant anvil.

The four legs of the hammer were hollow and made of cast iron. They were 10.25 meters tall. At the top, they were connected to form a strong A-shape by a 30-ton "table." This table helped guide the hammerhead and spread out the shock from its hits. One of the legs held the platform where the operator stood to control the machine.

The steam cylinder itself was 6 meters high. It had an inside width of 1.9 meters. Steam pressure, usually about 5 kg/cm2 (71 psi), pushed the cylinder upwards. After that, gravity would pull the hammer down to deliver its powerful blow.

The piston could move up to 5 meters. The rod connected to it was 35 centimeters wide. The hammerhead, also called the tup, could be changed. Different shapes of dies could be attached. This might be why the hammer's force was sometimes reported as 75 tons and sometimes 100 tons. The actual energy from a hit could be around 3.3 million foot-pounds.

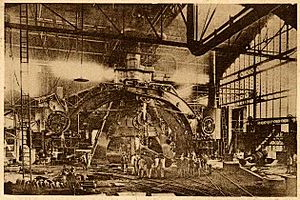

Four separate furnaces created steam for four nearby cranes. These cranes were used to move the very heavy 120-ton iron and steel blocks, called ingots, to the hammer for shaping. Six Bessemer converters made the steel for these ingots. A special railway line was built to carry them through the factory.

To give you an idea of its size, the biggest modern hydraulic forging presses can apply a force of about 80,000 tons.

Amazing Demonstrations

When the hammer was new, it sometimes showed off its amazing accuracy to the public. It could gently put a cork into a bottle. It could crack a nut without harming the nut inside. It could even tap a watch glass without breaking it. These demonstrations showed how precise these huge steam hammers could be.

Why It Was Replaced

Over time, steam hammers were replaced by hydraulic and mechanical steel presses. These newer machines could apply force more smoothly. This helped create better quality metal products. The giant American hammer that was bigger than the Creusot hammer was taken down by 1902. However, the Creusot hammer worked for much longer, for 54 years, until it was finally retired in 1930.

A Popular Tourist Spot

In 1969, the Creusot hammer was taken apart and then put back together in the town square of Le Creusot. It no longer works, but it stands as a tourist attraction. It reminds everyone of a past time when amazing technology was created.

| Ernest Everett Just |

| Mary Jackson |

| Emmett Chappelle |

| Marie Maynard Daly |