Energy Technology Engineering Center facts for kids

The Energy Technology Engineering Center (ETEC) was a special place in Ventura County, California. It was a group of industrial buildings located inside the large Santa Susana Field Laboratory (SSFL). ETEC's main job was to test parts for nuclear reactors. But instead of using water or gas to transfer heat, they used liquid metals.

ETEC was open from 1966 to 1998. Now, the site is being cleaned up by the U.S. Department of Energy. They are removing old buildings and cleaning the environment.

Contents

What was ETEC's purpose?

ETEC started in 1966 as the Liquid Metals Engineering Center (LMEC). It was created by the U.S. Atomic Energy Commission. Their goal was to test parts for nuclear reactors that used liquid metals. They also had a library, the Liquid Metals Information Center (LMIC). This library collected technical information about liquid metals. Both LMEC and LMIC helped the U.S. government's program for a special type of reactor called a Liquid Metal Fast Breeder Reactor.

These centers were built in a part of the Santa Susana Field Laboratory called Area IV. In 1978, LMEC's job grew to include other energy technologies. That's when it was renamed the Energy Technology Engineering Center (ETEC).

Why did ETEC use liquid sodium?

Most of ETEC's research focused on metallic sodium. This was because the planned Fast Breeder Reactor needed liquid sodium to work. Sodium was a good choice for several reasons:

- It transfers heat very well.

- It works at a low pressure compared to water.

- It has a fairly low melting point.

ETEC tested many different parts that would be used with liquid sodium. These included steam generators, pumps, valves, flow meters, and various instruments. They also studied how metal pipes reacted to very high temperatures over long periods. The goal was to make these parts safer and more reliable for nuclear reactors.

ETEC had unique facilities to test these parts with liquid sodium. One of them was the Sodium Pump Test Facility. This facility could move up to 55,000 gallons of liquid sodium every minute! It could also heat the sodium up to 1300°F (704°C). It was the biggest sodium pump test facility in the world.

Who operated ETEC?

The LMEC was first run by a company called Atomics International. Later, through a merger, it was operated by Rockwell International. In 1996, The Boeing Company bought Rocketdyne and took over the ETEC contract with the Department of Energy.

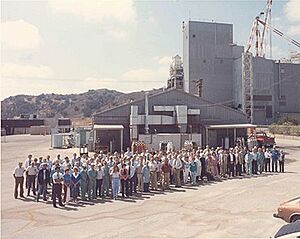

ETEC was part of Atomics International, but it operated separately. This was to make sure the company didn't get an unfair advantage from government research. At its busiest time in 1973, ETEC had 450 employees.

Today, the U.S. Department of Energy is in charge of cleaning up any environmental issues. This includes impacts from sodium or radioactive materials in Area IV of SSFL.

How was waste managed at ETEC?

Parts that had been used in sodium tests needed careful handling. This is because any leftover sodium reacts strongly with water. This reaction can be dangerous for people and the environment. Sometimes, large amounts of sodium also needed to be disposed of.

Before 1976, ETEC had its own site for treating and disposing of sodium waste. This site was called the Former Sodium Disposal Facility (FSDF). It was located at the far western edge of Area IV. At the FSDF, components were cleaned by reacting the sodium with steam or by putting them into a large pool of water. This process removed the hazardous sodium.

In 1978, new federal rules for waste management came out. ETEC then created the Hazardous Waste Management Facility (HWMF). This facility was specifically designed to remove sodium from used parts. The HWMF followed the new rules and closed in 1998.

What were the environmental impacts?

The work done at ETEC caused some contamination to the environment. Even though the FSDF was not meant for chemicals or radioactive materials, some of these materials were found there. A report from Boeing mentioned that "a small amount of very low level radioactive waste was inadvertently disposed of at the site."

The contaminated soil was removed from the FSDF in 1992. More cleanup was done in 1999 to remove traces of mercury and Polychlorinated biphenyls (PCBs) from the area.

Other parts of Area IV and the rest of SSFL have been under environmental investigation since 1994. This investigation is watched over by the California Department of Toxic Substances Control. By 2007, most of the sodium-related facilities at ETEC were removed. All the metallic sodium has also been taken away from ETEC.

What else happened at Santa Susana Field Laboratory?

Most of the 2,850-acre Santa Susana Field Laboratory (SSFL) was used for testing rocket engines. This was done by Rocketdyne for over 50 years. These engines were first for defensive missiles and later for National Aeronautics and Space Administration (NASA) space vehicles. This work happened in Areas I, II, and III of SSFL. The ETEC site itself was about 90 acres within Area IV.

Since the 1990s, there have been many environmental investigations across SSFL, including at ETEC. The goal is to figure out how to clean up the site. Some smaller cleanups have already happened, like cleaning contaminated surface water. The cleanup work for chemicals and radioactive toxins is managed by the California Department of Toxic Substances Control (DTSC).

The cleanup work is paid for by the "Responsible Parties." For the ETEC site, these are the U.S. Department of Energy (DOE) and The Boeing Company. For the rest of SSFL, Boeing and/or NASA are responsible. This depends on the specific area, the type of contamination, and where the toxins are found (like in soil, aquifers, or deep rock).

| James Van Der Zee |

| Alma Thomas |

| Ellis Wilson |

| Margaret Taylor-Burroughs |