Graber Olive House facts for kids

The Graber Olive House in Ontario, California, is a very old and famous place. It is the original spot for the longest-running olive packing business in the United States. The family home, where the special Graber Olives were first made, is now a historic landmark. The original farm is also a historic site. The business started in 1894. This was two years after Clifford C. Graber and his brother, Charles, came from Clay City, Indiana.

Contents

History of Graber Olives

How the Business Started

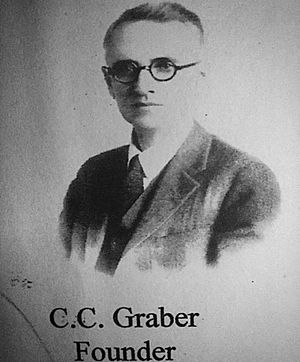

Clifford Graber, who was 19 years old, bought land in Ontario. He started by growing citrus fruits. But he really loved the taste of olives grown nearby. So, he decided to plant his own olive trees. He also learned how to prepare them.

His olives became very popular. Soon, he started a small business. In 1894, just two years after planting his trees, Graber began selling his special olives. These olives were prepared in large vats.

Family Involvement and Growth

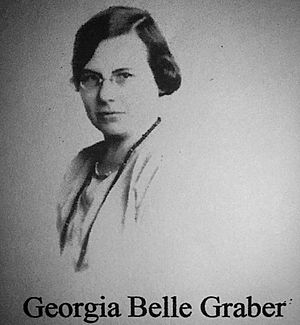

Clifford married Georgia Belle Noe in 1905. She helped with the business. She even sold fresh olives directly from the vats.

By 1910, Graber had invented a special machine. It used ropes to sort olives by their size. Around the same time, he began putting his olives into cans. Ten years later, he grew his business even more. He planted his special Manzanilla olive trees in Hemet, California.

In 1934, Graber made his canning factory bigger in Ontario. Nine years later, his sons, Robert and William, took over the business. Cliff Graber stayed involved until he passed away in 1955. He was 83 years old.

Moving the Groves

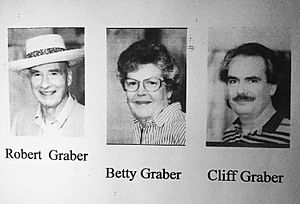

By 1963, Robert ("Bob") Graber became the only owner. Bob was born in the family home on the olive property. He and his wife, Betty, kept working in the family business. Their son, Cliff, also joined them.

Around that time, Bob Graber moved the olive growing part of the business. He moved it to 75 acres of olive groves. These groves are in the San Joaquin Valley, near Porterville, California. The olive groves are still there today.

Every fall, during harvest season, the olives are picked. Then they are driven from Porterville to Ontario. This journey takes about two months. Once in Ontario, the olives are canned.

In 2020, the Graber Olive House property was officially named a historic district. This was done by the City of Ontario.

How Graber Olives Are Made

Unique Olive Harvesting

The Graber Olive House says its olives are special. This is because they are left on the tree to ripen fully. Only then are they picked. This information comes from Flo Duncan, who works there. She also mentioned that the business does not use computers for its main operations.

Processing the Olives

When the olives arrive in Ontario, they are first sorted by size. Then, they are placed in one of 550 large concrete vats. They stay there for three weeks to be cured. The water and salt solutions in the vats are changed every day.

After leaving the vats, the olives move along a conveyor belt. Employees then scoop them by hand into aluminum cans. A special machine seals the cans tightly. It uses 200-degree steam to do this.

Next, giant pressure cookers, called retorts, are used. They heat and pressurize the cans for 62 minutes at 242 degrees Fahrenheit. After the cans cool down, a labeling machine adds their labels. It also shows their size. The smallest olives are size 12, and the largest are size 16.

From Tree to Can

It takes a little more than three weeks for Graber Olives to go from the tree to the can. In a good season, the business processes about 150 tons of olives. They ship these olives to stores and customers all over the world.

The Graber Olive House closed during the COVID-19 Pandemic. As of August 2025, they remain closed. Their website is not working, and their social media pages are no longer updated.

Graber Olives in Media

Television Features

In May 2020, the Graber Olive House was shown on a TV show. It was an episode of Ghost Adventures. The episode was called "The Graber Family Farm." The owner, Robert Graber Jr., and his staff shared stories. They talked about strange happenings they experienced in the vat room. This TV appearance helped the business get more attention.