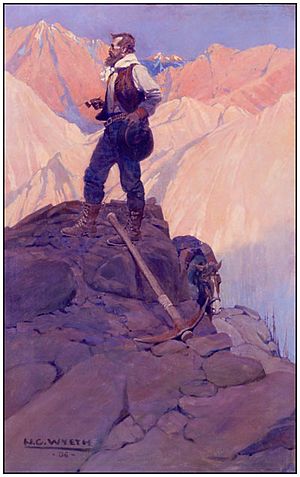

Mineral exploration facts for kids

Mining engineering is a cool type of engineering. It's all about finding, digging up, and processing valuable minerals from the Earth. Think of it like treasure hunting, but with a lot of science and planning!

Mining engineers don't just dig. They also figure out how to make these minerals more useful. But here's the important part: digging can change the natural environment. So, mining engineers also work hard to protect the Earth. They try to fix any damage caused by mining, both during and after the work is done. It's about getting what we need while being kind to our planet.

Contents

Finding Minerals: The First Step

Mining engineers are involved in almost every step of a mining project. Their first big job is to find mineral deposits. Then, they figure out if it's worth digging them up.

How Do We Find Minerals?

Mining engineers team up with geologists to find places where minerals are hidden. First, they decide which minerals to look for. They might drill into the ground to get samples. They also check the surface of the land. They look for specific compounds or ores.

For example, they might search for galena to find lead. Or they might look for chalcopyrite to find copper. They also search for non-metals like phosphate, quartz, or coal.

They get clues from mineral maps and science reports. Old well logs or even local stories can help too. Sometimes, they use satellite pictures to spot possible areas. If the land is privately owned, the owner might even be the first to find the minerals!

Checking Out the Minerals

Once a possible mineral spot is found, the mining engineer checks its properties. They might do chemical tests to see what the ore is made of. After they know what it is, they figure out how much of it there is. This means finding out how big the deposit is and how pure the mineral is.

Engineers drill more samples to find the edges of the mineral deposit. Then, they calculate how much valuable material is in that area.

Is It Worth It? A Study

After finding the mineral and knowing how much is there, the next step is to see if it's worth digging. This is called a feasibility study. It's like planning a big project.

First, they do a quick check. They look at how much people need the mineral. They also see how much rock they'd have to move to get it. And they estimate the costs. This helps them decide if the project will likely make money. If it looks good, they do a deeper study.

This bigger study looks at everything. It includes the cost to start the mine and how to dig the minerals. They also estimate how long it will take to earn back the money. They look at how much money they expect to make. They also consider what happens to the land afterward. Plus, they think about environmental rules and permits. All these steps help them decide if the mining company should go ahead. Sometimes, they might sell the rights to another company. Or they might wait until the market is better.

Working in a Mine: The Operation

Mining engineers who work at an active mine do many things. They might try to make operations better. They also look for more minerals nearby. They decide where to add new equipment or hire more people. They can also supervise workers or manage the mine. Some even sell equipment or minerals.

Mining engineers also work as environmental, health, and safety managers. They design ways to keep everyone safe and protect the environment.

The way minerals are dug up depends on many things. These include the type of mineral, the geology of the area, and where the mineral is located. Things like how hard the mineral is or how it's layered in the ground matter. How easy it is to reach the mineral also affects the method.

Generally, mining is done either on the surface or underground. Sometimes, both methods are used at the same site.

Surface Mining: Digging from the Top

Surface mining makes up about 90% of the world's mineral production. It's also called open pit mining. This method removes minerals that are at or near the Earth's surface. It often changes the land's shape and features.

One type is quarrying. This involves digging up hard minerals like limestone, sand, gravel, and slate. Machines cut, cleave, and break the rock. Often, explosives are used to help break up the hard rock. This creates a series of steps, like benches.

Another type is strip mining. This is used for softer minerals like clays and phosphate. Large mechanical shovels and loaders scoop them up. Softer coal seams can also be dug this way.

With placer mining, minerals are taken from the bottom of lakes, rivers, or even the ocean. This is done using a special boat called a dredge. Also, in-situ mining can be done from the surface. This uses liquids to dissolve the ore underground. Then, the liquid with the dissolved mineral is pumped up.

The Mining Process: Blasting Rocks

Explosives are often used to break up rock formations. This helps collect the ore. This process is called blasting. Blasting uses the heat and huge pressure from the explosives to shatter rocks.

Mining engineers choose the right explosives. They also decide where to place them. This helps make sure the blasting is efficient and safe. Blasting is used in many parts of mining. It helps build tunnels and also helps get the ore out.

| Charles R. Drew |

| Benjamin Banneker |

| Jane C. Wright |

| Roger Arliner Young |