Industrial robot facts for kids

An industrial robot is a special kind of robot system used in factories for manufacturing. These robots are automated, meaning they can work on their own. They can also be programmed to move in many different ways.

Robots are used for many tasks like welding, painting, putting things together (assembly), taking things apart (disassembly), and moving items from one place to another (pick and place). They also help with packaging and labeling, stacking products on pallets, checking products, and testing. Robots do these jobs very quickly and precisely. They are also great at material handling, which means moving materials around.

In 2021, there were about 3.5 million industrial robots working around the world, according to the International Federation of Robotics.

Contents

Types of Industrial Robots

There are six main types of industrial robots, each designed for different tasks.

Articulated Robots

Articulated robots are the most common type. They look a lot like a human arm and are often called robotic arms. They have several "joints" that allow them to move in many directions, giving them a wide range of motion.

Cartesian Robots

Cartesian robots are also known as gantry robots or x-y-z robots. They move along straight lines, like a crane. They have three sliding joints for moving their tool and three rotating joints to change its direction. To move and turn their tool in all directions, they need six axes (or ways to move).

Cylindrical Robots

Cylindrical coordinate robots have a rotating joint at their base and at least one sliding joint. This allows them to move up and down, and in and out, like a cylinder. Their design helps them reach tight spaces quickly.

Spherical Robots

Spherical coordinate robots only have rotating joints. They were some of the first robots used in factories. Today, they are often used for tasks like feeding machines in factories and for welding.

SCARA Robots

SCARA stands for Selective Compliance Assembly Robot Arm. These robots are known for their two parallel joints that allow them to move mostly in a flat, X-Y plane. They are great for jobs that need very precise side-to-side movements, making them perfect for assembly tasks.

Delta Robots

Delta robots are also called parallel link robots. They have several arms connected to a single base. Delta robots are very fast and are often used for quick "pick-and-place" tasks, like sorting small items.

Industrial robots can also have different structures: serial or parallel.

Serial Robots

Serial robots are the most common industrial robots. They are built like a chain of links connected by motor-powered joints. The robot's arm extends from a base to its end tool. SCARA robots are good examples of this type.

Parallel Robots

A parallel robot is designed with several short, strong chains. This makes them very stiff and stable. If one chain has a small error, the others help to balance it out, making the robot very precise.

How Robots Work on Their Own

Robots can work with different levels of independence.

Some robots are programmed to do the same actions over and over again, exactly the same way every time. These actions are set by routines that tell the robot how to move, how fast, and how far.

Other robots are much smarter. They can adjust to different objects or even figure out what task needs to be done. For example, many robots use machine vision (like cameras) to "see" what they are working on. Artificial intelligence is also becoming very important in making modern industrial robots even more capable.

History of Industrial Robots

The first known industrial robot was built by Bill Griffith P. Taylor in 1937. It was like a crane made mostly from Meccano parts and powered by one electric motor. This robot could move in five ways, including grabbing and rotating objects. It used punched paper tape to control its movements and could stack wooden blocks in patterns.

George Devol applied for the first robot patents in 1954. The first company to make a robot was Unimation, started by Devol and Joseph F. Engelberger in 1956. Unimation robots were first used to move objects from one place to another. They were very accurate. Unimation later shared its technology with companies in Japan and England.

In 1969, Victor Scheinman at Stanford University created the Stanford arm. This was an all-electric robot arm with six axes, designed to move smoothly along any path. This opened up new uses for robots, like assembly and welding. Scheinman later sold his designs to Unimation, which developed them further with General Motors and called them the Programmable Universal Machine for Assembly (PUMA).

Industrial robotics grew quickly in Europe. Both ABB Robotics and KUKA Robotics introduced their first robots in 1973. ABB's IRB 6 was one of the first commercially available robots controlled by a computer. KUKA's FAMULUS was also one of the first articulated robots with six electric axes.

More companies in the US joined the robot industry in the late 1970s, including big names like General Electric and General Motors. By the mid-1980s, many companies were making industrial robots. Today, some of the major robot makers outside of Japan include Adept Technology, Stäubli, ABB Asea Brown Boveri, KUKA Robotics, and Comau.

How Industrial Robots Work

Key Features of Robots

- Number of axes: This tells you how many ways a robot can move. Two axes let it move on a flat surface, and three let it move in 3D space. To fully control the tool at the end of the arm, like a wrist, three more axes are needed for turning.

- Working area: This is the space a robot can reach.

- Carrying capacity: How much weight a robot can lift.

- Speed: How fast the robot can move its arm.

- Accuracy: How close a robot can get to a specific position it's told to go to.

- Repeatability: How well the robot returns to a position it has been taught before. This is usually more important for robots than accuracy.

- Power source: Most modern robots use electric motors, which are faster. Older ones sometimes used hydraulics.

- Compliance: How much a robot's arm might move or bend when a force is applied to it, like when it's carrying a heavy load.

Programming Robots

Setting up or programming an industrial robot usually involves connecting it to a laptop, desktop computer, or a network.

A robot and the machines it works with are often called a "workcell." For example, a cell might have a robot, a parts feeder, and a molding machine. All these machines are connected and controlled by a central computer. The robot needs to be programmed to work with these other machines.

Software: Special robot software helps make programming easier. This software runs either in the robot's controller or on a computer.

You need to teach the robot two main things: 1. Positions: Where the robot needs to go. 2. Procedure: The steps the robot needs to follow.

There are several ways to teach a robot positions:

- Using commands: You can tell the robot where to go by typing in X-Y-Z coordinates or using a graphical interface.

- Teach pendant: This is a handheld device with buttons. You can use it to manually move the robot to the exact spot you want, then save that position. Teach pendants always have a large emergency stop button for safety. They also have a "deadman switch" that stops the robot if you let go or press too hard, making it safer to use.

- Lead-by-the-nose: With this method, you can physically move the robot's arm to the desired positions or along a path. The robot's software records these movements. This is often used for tasks like paint spraying.

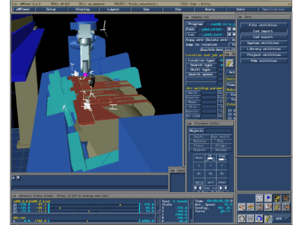

- Offline programming: This is when you program the robot using a computer simulation, without needing the actual robot. You can create a virtual model of the robot and its workspace. This saves time and allows you to test different scenarios safely before running them on the real robot.

End-of-arm tooling: The tool attached to the end of the robot's arm is called the "end effector" or "end-of-arm-tooling" (EOAT). Common examples include welding tools, spray guns, grinding tools, and grippers (which grab objects). These tools are often complex and designed to handle specific products.

Controlling Movement

To make a robot move, you need to tell it where its end tool should be. This is usually done by giving it X, Y, and Z coordinates, along with how the tool should be turned (yaw, pitch, and roll). The robot's controller then figures out the exact angles for each of its joints to reach that position. This process is called kinematics.

It's much easier for a person to think about moving a robot left/right or up/down than to control each joint separately. So, teach pendants often let you move the robot in these simple X-Y-Z directions.

Simple Robot Program Example

Most robots work by remembering a series of positions and moving between them. Imagine a robot moving items from bin A to bin B:

First, you define the important points:

- P1: A safe spot above the work area.

- P2: 10 cm above bin A.

- P3: The exact spot to pick up a part from bin A.

- P4: 10 cm above bin B.

- P5: The exact spot to place a part in bin B.

Then, you create the program steps: 1. Move to P1. 2. Move to P2. 3. Move to P3. 4. Close the gripper (to pick up the part). 5. Move back to P2. 6. Move to P4. 7. Move to P5. 8. Open the gripper (to drop the part). 9. Move back to P4. 10. Move to P1 and finish.

After programming, the teach pendant is usually disconnected, and the robot runs the program stored in its own controller.

Robot Movement Challenges (Singularities)

Sometimes, a robot can get into a "singularity" position. This happens when two or more of its joints line up in a way that makes the robot's movement unpredictable or causes it to try to move too fast. For example, if a robot's wrist joints line up, it might try to spin 180 degrees instantly. This can be bad for the robot and the task it's doing. Robot makers try to design robots to avoid these situations or slow them down when they get close to a singularity.

Industrial Robot Market

The International Federation of Robotics reported that by the end of 2021, about 3.5 million industrial robots were in use worldwide. In 2018, the global sales of industrial robots were estimated to be $16.5 billion. When you add the cost of software and other equipment, the total market for robot systems was about $48 billion in 2018.

China is the biggest market for industrial robots, with over 154,000 units sold in 2018. China also has the largest number of robots working in factories, with nearly 650,000 at the end of 2018.

The biggest users of industrial robots are:

- Automotive (car manufacturing) industry: 30%

- Electrical/electronics industry: 25%

- Metal and machinery industry: 10%

- Rubber and plastics industry: 5%

- Food industry: 5%

Safety with Robots

The International Federation of Robotics expects many more industrial robots to be used in factories around the world. While robots can make workplaces better, they also bring new safety challenges.

Between 1992 and 2015, researchers found 61 robot-related deaths in the US. The US government's Occupational Safety and Health Administration (OSHA) has also investigated many robot-related injuries and deaths. As more robots, especially those that work alongside humans, are used, injuries could increase.

To keep workers safe, safety standards are being developed. Organizations like the Robotic Industries Association (RIA) and the American National Standards Institute (ANSI) are working on these rules. OSHA, NIOSH (a US safety research agency), and RIA have teamed up to share knowledge and find ways to reduce dangers in workplaces with robots. NIOSH has also started a research center to guide the safe use of robots. Their goal is to make sure robots improve worker safety and well-being.

See also

In Spanish: Robot industrial para niños

In Spanish: Robot industrial para niños

- Automation

- Domestic robot

- Intelligent industrial work assistant (iiwa)

- Lights out (manufacturing)

- Mobile industrial robots

- Cartesian coordinate robot

- Gantry robot

- Workplace Robotics Safety

Images for kids

| Aurelia Browder |

| Nannie Helen Burroughs |

| Michelle Alexander |