Automation facts for kids

Automation is the use of technology to perform tasks with reduced human assistance. It involves machines, computers, and robots doing work that people used to do. Automation is used in many different fields, such as manufacturing, transportation, and even in our homes.

The main goal of automation is to make processes faster, safer, and more accurate. While simple machines have existed for a long time, modern automation uses advanced computers and electronic devices. Today, automation is found in everything from thermostats that control the temperature in a house to giant robots that build cars in factories.

Contents

What is Automation?

Automation describes a wide range of technologies that reduce the need for human intervention. It usually involves three main parts:

- Sensors: These are like the eyes and ears of the machine. They measure things like temperature, speed, or size.

- Controllers: These are the "brains" of the system, often a computer. They decide what to do based on information from the sensors.

- Actuators: These are the parts that move or perform the action, like a motor or a valve.

For example, a household thermostat measures the air temperature. If it gets too cold, the controller tells the heater to turn on. When it gets warm enough, it tells the heater to turn off. This is a simple form of automation.

History of Automation

Ancient Inventions

People have been trying to build automatic machines for thousands of years. In ancient Greece and the Arab world (between 300 BC and 1200 AD), inventors created devices to keep track of time.

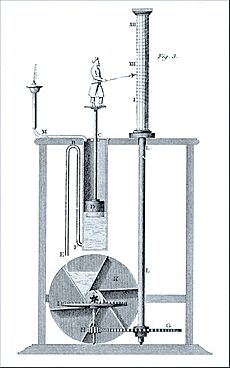

In Ptolemaic Egypt, an inventor named Ctesibius described a special regulator for a water clock around 270 BC. It worked similarly to the float ball in a modern toilet tank. This was one of the earliest examples of a machine that could control itself. Later, in the 14th century, mechanical clocks replaced water clocks.

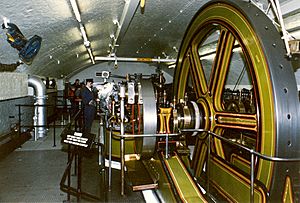

The Industrial Revolution

The Industrial Revolution in the 18th century brought major changes. The invention of the steam engine meant that machines could do heavy work.

In 1788, James Watt adapted a device called a centrifugal governor for his steam engine. This device spun around and helped keep the engine running at a steady speed without a human having to constantly adjust it. This was a very important step in the history of automatic control.

During this time, inventors also created automated machines for making cloth. Joseph Marie Jacquard invented a loom in 1800 that used punch cards to weave complex patterns automatically. This idea of using cards to give instructions was later used in early computers.

The Computer Age

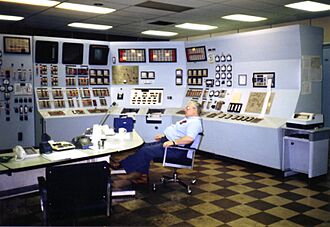

In the 20th century, electricity and electronics changed automation again. In the 1920s, factories began using electricity to power their machines. Control rooms were built where people could watch lights and gauges to see how the factory was running.

By the 1950s, computers began to take over. Engineers developed digital controls that were much more precise than the old mechanical ones. Today, almost every factory uses computers to control production. This is sometimes called the "Digital Revolution."

How Automation Works

Control Systems

Automation relies on control systems. The most common type is a closed-loop system. This means the system constantly checks its own work.

Think of a driver steering a car. The driver looks at the road (sensor), decides where to turn (controller), and turns the steering wheel (actuator). If the car drifts, the driver corrects it. An automated system does this same process using electronics instead of a human brain.

Feedback Loops

A key concept in automation is negative feedback. This is when a system detects a change and acts to correct it. For example, if a cruise control system on a car sees the speed dropping because of a hill, it adds more power to the engine to keep the speed steady.

Uses of Automation

In Factories

Manufacturing is one of the biggest users of automation. Robots are used to weld parts, paint cars, and assemble electronics.

- Robots: Industrial robots can lift heavy objects and work in dangerous environments.

- CNC Machines: These are computer-controlled tools that cut metal and wood with extreme precision.

- Lights-out manufacturing: Some factories are so automated that they can run with almost no humans inside, meaning they can work with the lights off!

In Our Homes

Automation has become a big part of daily life.

- Appliances: Washing machines and dishwashers go through different cycles automatically.

- Smart Homes: Many houses now have systems that control lights, locks, and heating automatically or through a smartphone app.

- Cleaning: Robot vacuum cleaners can navigate around a room to clean floors on their own.

In Transportation

- Aviation: Airplanes use autopilot to fly for long periods without the pilot touching the controls.

- Self-driving cars: Companies are developing cars that can drive themselves using cameras and sensors to see the road.

- Trains: Many subway systems around the world are fully automated and do not have a driver on board.

In Stores and Restaurants

- Retail: Self-checkout machines allow shoppers to scan and pay for their items without a cashier.

- Food Service: Some restaurants use tablets for ordering, and some even use robots to cook food or deliver it to tables.

- Vending Machines: These are simple automated shops that dispense snacks or drinks when money is inserted.

Advantages and Disadvantages

Benefits

Automation has many positive effects:

- Safety: Robots can do dangerous jobs, like handling hot metal or toxic chemicals, keeping humans safe.

- Productivity: Machines can work 24 hours a day without getting tired, making products faster and cheaper.

- Quality: Automated machines perform tasks exactly the same way every time, reducing mistakes.

- Convenience: Automated devices in our homes save us time on chores.

Challenges

There are also some downsides to automation:

- Cost: Buying and installing robots and computers is very expensive.

- Maintenance: Complex machines require skilled technicians to fix them when they break.

- Security: Computer-controlled systems can sometimes be hacked or have software errors.

- Job Changes: As machines take over routine tasks, some jobs disappear. This can be difficult for workers who need to learn new skills.

The Future of Work

Many people worry that automation will take away jobs. This is a topic called technological unemployment. Throughout history, technology has changed how people work. When tractors were invented, fewer people were needed on farms, but new jobs were created in factories.

Today, automation is replacing jobs that are repetitive or dangerous. However, it is also creating new jobs in programming, engineering, and robot maintenance. Experts believe that in the future, humans will work more on tasks that require creativity, problem-solving, and social skills—things that machines are not good at yet.

Images for kids

See also

In Spanish: Automatización para niños

In Spanish: Automatización para niños

- Artificial Intelligence

- Automate This

- Automated storage and retrieval system

- Automation engineering

- Automation Master

- Automation technician

- Cognitive computing

- Control engineering

- Critique of work

- Cybernetics

- Data-driven control system

- Dirty, dangerous and demeaning

- Feedforward control

- Fully Automated Luxury Communism

- Futures studies

- The Human Use of Human Beings

- Industrial Revolution

- Industry 4.0

- Intelligent automation

- Inventing the Future: Postcapitalism and a World Without Work

- Machine to machine

- Mobile manipulator

- Multi-agent system

- Post-work society

- Process control

- Productivity improving technologies

- The Right to Be Lazy

- Right to repair

- Robot tax

- Robotic process automation

- Semi-automation

- Technological unemployment

- The War on Normal People

| Precious Adams |

| Lauren Anderson |

| Janet Collins |