Irvinebank State Treatment Works facts for kids

Quick facts for kids Irvinebank State Treatment Works |

|

|---|---|

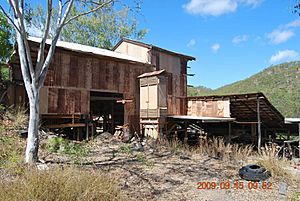

Irvinebank State Treatment Works, 2009

|

|

| Location | Off Jessie Street, Irvinebank, Shire of Mareeba, Queensland, Australia |

| Design period | 1870s - 1890s (late 19th century) |

| Built | 1883 - c. 1908 |

| Official name: Irvinebank State Treatment Works, Loudoun Mill | |

| Type | state heritage (archaeological, built) |

| Designated | 21 October 1992 |

| Reference no. | 600679 |

| Significant period | 1880s-1910s (fabric) 1880s-1980s (historical) |

| Significant components | formation - railway, school of arts, machinery/plant/equipment - mining/mineral processing, weir, railway station, shed - goods, bank, residential accommodation - manager's house/quarters, office/administration building, mill, workshop |

| Lua error in Module:Location_map at line 420: attempt to index field 'wikibase' (a nil value). | |

The Irvinebank State Treatment Works, also known as Loudoun Mill, is a special historical site in Irvinebank, Queensland, Australia. It's a place where tin ore was processed to extract the valuable metal. This important site was built between 1883 and around 1908. It was officially added to the Queensland Heritage Register on 21 October 1992, recognising its historical value.

Contents

The Story of Irvinebank's Tin Works

Early Tin Discoveries

In 1882, a group of prospectors from Herberton found tin at a place called Gibbs Camp. This area was about 16 kilometres west of Watsonville. The best tin found there was very rich, with 60% pure tin. After trying to process the tin for months without success, the miners wanted to sell their land. They hoped someone with the right machinery would buy it.

John Moffat and the Loudoun Mill

In October 1883, the Gibbs Creek properties were bought by the Glen Smelting Company. The main owner was John Moffat, a well-known mining businessman from Herberton. This purchase helped Moffat grow his investments and influence in North Queensland tin mining.

The Glen Smelting Company immediately started building a smelter at Gibbs Creek. Moffat renamed the area Irvinebank, after his birthplace in Scotland. They chose a sloping area between Gibbs and McDonald's Creeks for the mill. Here, they built a strong dam to provide water for the concentrating mill. Moffat also bought a five-head battery (a machine for crushing ore) from 14 kilometres away and set it up above the new dam.

This battery was likely one of the first in Australia to use a continuous flow system for processing tin. The mill had six levels on the hillside. Ore was fed automatically from tramway hoppers to the crushing stamps. Between the second and fifth levels, machines called jiggers and Cornish buddles slowly rotated. These were powered by a large 6-metre water wheel. Below these were tanks for settling the tin. In February 1889, Moffat built a house for himself, called Loudoun House, with an office underneath. It had a wide verandah overlooking the dam.

Mill Operations and Growth

The battery and smelter started working in December 1884. It was named the Loudoun Mill, after Moffat's family in Scotland. The mill was worth about £12,000 and was managed by George McTavish. In its first year, the Loudoun Mill crushed 3,840 tonnes of ore. This produced 651 tonnes of black tin, which then became 438 tonnes of pure metallic tin after smelting.

The growth of tin mining on the Atherton Tablelands depended on how much the Loudoun Mill could crush and its processing fees. More crushing machines were added over the years: five more heads in 1886, 1893, and 1899, and ten more in both 1901 and 1904. The tin separation equipment was also improved several times. By then, the mill's value had increased to £40,000.

John Moffat was known for using older technology, even though he did install some newer machines like frue vanners in 1890. The mill's look changed with new chimneys added in 1903, 1905, and 1906. A Krupp ball mill was replaced in 1908. In 1909, a government geologist named L. C. Ball visited the works. He noted that the 40-head stamper battery was not well arranged and used a lot of steam. He also said that Irvinebank was "the chief tin-mining centre of Queensland."

At its busiest, this was the largest tin crushing and smelting plant in Australia. It was connected by a narrow-gauge tramway, the Stannary Hills tramway, from Boonmoo siding. Moffat was involved in many other mines, but the Irvinebank mines were his most important.

Challenges and State Ownership

The Irvinebank Mining Company faced problems as tin quality dropped, prices fell, and debts grew. The Queensland National Bank made Moffat step down as a director in 1912. Changes to his mines caused problems with workers. World War I scattered many miners, and the European market collapsed in 1914, forcing the works to close.

In 1919, the Irvinebank Mining Company was closed down. Edward Theodore, who was the Premier of Queensland and a former miner from Irvinebank, bought the Loudoun Mill, tramway, and mines for £22,500. This happened on 25 October 1919, making it a State Enterprise (owned by the government). The old steam power plant was replaced with a more modern suction gas system.

Later Changes and Modern Operations

In 1929, the works were given to a private company, the Whitworth Finance and Mining Corporation Limited. But they failed during the Great Depression, which hurt the local tin industry. The smelters were taken apart, and the chimney stacks were blown down. As tin ore became harder to find, the Loudoun Mill was just a shadow of its former glory.

In May 1934, when Charles Edford became manager, the mill was much like it was in 1919. With help from the Mines Department, he updated it in 1935. He installed new machines and processes to extract tin more efficiently. In 1951, more modern equipment was added. Throughout the 1950s, the State Government invested £5,000 each year into the town for electricity, housing, and more milling equipment. The old crushing stamps were finally stopped in 1966. Today, the mill uses modern crushers, rod and ball mills, and vibrating screens to process ore.

In 1981, the State Government decided to transfer the treatment works, which was the last of the State Enterprises started by Premier Theodore. Since July 1983, the Hilla family has operated the works. The Irvinebank State Treatment Works (Sale and Operation) Act 1990 sets out the rules for its continued operation.

What You Can See at the Site

The Irvinebank State Treatment Works covers an area where Gibbs and McDonald's creeks meet in the middle of Irvinebank. This area includes many buildings and structures related to processing minerals, railways, homes, and community activities. The remains show how a modern (for the late 1800s) processing plant was laid out and how technology changed over time.

Key Buildings and Structures

The main building is the mill itself. It now uses electric power and continues to process local tin ore. You can still see parts of the old mill, like timber ore bins (no longer used), a primary crusher, and foundations of early ball mills and blast furnaces. There are also foundations of the boiler house and chimney, plus a workshop and a carpenters' shop.

On the northern side of the area, there are three important buildings:

- The School of Arts Hall: This is a wooden building used as a community hall.

- The former Queensland National Bank: This brick building is now used as a home.

- Moffat's old house and office (Loudoun House): This group of wooden buildings includes the house, which is now a museum.

The railway station and a large goods shed are still there. You can also see the old railway track path and the foundations of the engine shed. The early smelter works and assay office are mostly just archaeological remains on the surface now, as they were taken down and worn away over time. A strong log weir (a small dam) with stone and concrete still dams Gibbs and McDonald's creeks.

Surviving Machinery

Some of the old and newer machinery that you can still see includes:

- 2 Rod mills

- 2 Wilfley tables

- Jaw crusher

- Retort/furnace

- Frue vanner

- Four-Cylinder oil engine

- Lathes and other workshop equipment

- Concentrating and drying plant

Why This Site is Important

The Irvinebank State Treatment Works was listed on the Queensland Heritage Register on 21 October 1992 for several important reasons:

Queensland's History

The Loudoun Mill, known as the Irvinebank State Treatment Works for many years, is very important to Queensland's history. John Moffat, the mining leader based in Irvinebank, built a huge mining business in the Cairns area. This business exported metals worth £4 million over 25 years! The mill and treatment works have been the heart of Irvinebank town, supporting it economically and socially since 1884.

Unique Heritage

This site is one of the few surviving mining complexes that were set up as "State Enterprises" by the Ryan/Theodore Labor Government. This type of mill is rare in Australia and in North Queensland, with only the Emuford battery being similar.

Learning About the Past

The complex of mill buildings and machinery can teach us a lot about how tin processing technology and mining engineering developed in Queensland. Even though the old stamps and boilers are gone, some of the timber ore bins and tramway paths date back to 1884. Remains of the blast furnace flue, brick chimney base, smelter wall, and assay office are still there.

Technical Achievements

The mill shows the history of tin mining technology in North Queensland from the 1880s until today. The machinery, parts, and foundations in the mill can help us understand all the different processes and technologies used at the mill over its 110 years of operation.

Connection to John Moffat

The mill has a special connection to John Moffat. He owned and managed the Irvinebank Mining Company from 1884 to 1912. He was a key businessman who helped develop North Queensland between 1880 and 1918 by starting mines, building mills, towns, tramways, roads, and public buildings.

| Shirley Ann Jackson |

| Garett Morgan |

| J. Ernest Wilkins Jr. |

| Elijah McCoy |