Lal Lal Iron Mine and Smelting Works facts for kids

The Lal Lal Iron Mine and Smelting Works was a place near Lal Lal, Australia, where people tried to make iron a long time ago. It was located close to the Moorabool River and the Geelong–Ballarat railway line. From 1875 to 1884, a special furnace called a blast furnace was used here to turn iron ore into pig iron. They used iron ore found nearby, charcoal made from local trees, and limestone from another close spot.

Sadly, making iron at Lal Lal didn't make enough money in the end. It's important because it was the only time anyone tried to start an iron-making industry in Victoria. The old blast furnace building is still there today. It's one of only three 19th-century blast furnaces left in Australia, and the only one of its kind in the southern half of the world! This site is so special that it's listed on the Victorian Heritage Register.

Contents

Why Iron Was Needed

The Victorian gold rush in Australia created a huge need for machines to help miners. This led to many factories, called foundries, opening in Ballarat. One famous one was the Union Foundry, started by John Walker in 1865. These foundries made all sorts of metal parts, including parts for trains.

At that time, Australia had to buy most of its iron from other countries. This imported iron was often cheap because it was used as heavy ballast (weight) on ships coming to Australia. Because of this, it was hard for local iron-making businesses to compete. However, in the early 1870s, the price of iron around the world went up a lot. This made people in Australia think it was a good time to try making iron themselves, even though the high prices didn't last long.

Finding Minerals at Lal Lal

People looking for gold in the Lal Lal area also found other important minerals. Around 1857, lignite (a type of brown coal) was discovered. While lignite wasn't good for making iron, its discovery led to a railway siding being built at Lal Lal. This siding was later used to load pig iron onto trains and unload other materials like coke and limestone.

In the 1860s, iron ore was found near the Moorabool River, about 5 kilometers from Lal Lal. This iron ore was a type called limonite. It was found about 2 to 4 meters deep and covered a large area. People thought there might be around two million tons of this iron ore!

Scientists at the Ballarat School of Mines tested the Lal Lal iron ore. They found it had a good amount of iron metal, and importantly, it was low in phosphorus and sulfur. This was a big advantage because these elements can make iron weak. Also, the iron ore was close to the Ballarat foundries that needed pig iron, which was another plus.

Besides iron ore, limestone was found nearby at a place called 'Lowndes Bridge'. Limestone is a key ingredient in iron making, helping to remove impurities. There was also plenty of clay and trees on the land, which were used to make charcoal for the furnace.

How the Iron Works Operated

Early Days (1873-1875)

In November 1873, a group of people met to start the Lal Lal Iron Company. They had already tried smelting some Lal Lal ore at the Union Foundry in Ballarat, and it seemed promising. Work on building the blast furnace began in 1874. The first iron was successfully made on October 19, 1875.

However, the company faced big problems. They didn't have enough money to build a railway line to the mine. So, they had to use bullock teams to pull wagons over very bad roads. These roads were so poor that the iron works had to shut down for eight or nine months every winter because the roads became impassable due to wet weather. Making charcoal was also difficult in winter.

By January 1876, the company had made 127 tons of pig iron, but then their machinery broke down completely. They also realized their steam engine wasn't powerful enough. Because of these issues, the company decided to close down and try to reorganize with more money.

Restarting and New Plans (1876-1879)

In March 1876, a new company was formed to buy out the old one. They hoped to raise more money to get the iron works running again. By August 1878, new machinery was being installed. The existing furnace was updated and started making iron again on October 18, 1878. The Premier of Victoria, Graham Berry, officially opened the works on October 26, 1878. About 800 kilograms of iron were made that day.

By the end of 1879, the company realized the furnace wasn't big enough to make enough iron. So, they decided to build a much larger furnace. Work on this new, bigger furnace began in July 1880. It was designed to make 80 tons of iron each week.

Final Years of Operation (1880-1884)

The new, larger blast furnace started working on March 20, 1881. It was shut down on June 24, 1881, again because the roads became too muddy. The company also had its own factory, called a foundry, in Ballarat where they could turn the pig iron into useful items.

The new furnace started up again in February 1882. It worked well for a while, making 350 tons of iron, but then heavy rains stopped road transport once more. The much-needed tramway to the railway siding still wasn't built.

The company managed to buy old railway tracks to build their tramway. This tramway was finally finished and working by April 1884. It was a great success, meaning the iron works could operate all year round! The company soon had a huge pile of 500 tons of pig iron, but they couldn't sell it. Instead, they used it at their own foundry in Ballarat to make profitable castings (metal shapes).

In June 1884, the blast furnace at Lal Lal was stopped because they had too much iron. Unfortunately, the cost of making iron at Lal Lal was much higher than the price of imported iron. Because of this, the company decided to stop making iron at Lal Lal for good. The foundry in Ballarat continued to use the stored iron and remained profitable for some time.

The Lal Lal site was put up for sale several times in the following years, but no one bought it to restart the iron-making. By 1902, the smelter was in ruins. There were a few more attempts by different companies in the early 1900s to use the Lal Lal iron ore, but none of these plans ever worked out.

How the Technology Worked

Iron Making Process

The Lal Lal blast furnaces used an older method called 'cold blast'. This meant that the air blown into the furnace was not heated first. By the 1880s, newer 'hot blast' furnaces were common, which used less fuel and made more iron. The Lal Lal furnaces also had an 'open top', meaning the hot, poisonous gases from the furnace escaped into the air instead of being reused. The main reasons Lal Lal used this older technology were probably that it was cheaper to build and simpler to operate.

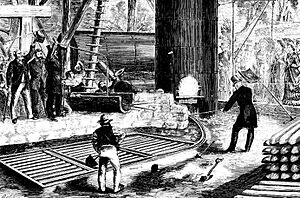

The second furnace was a tall structure, about 17 meters high. It had a strong stone base and an inner lining of special fire-bricks from England. The outside was made of local stone held together with iron bands. Workers would carry materials like iron ore, charcoal, and limestone across a wooden bridge from a nearby hillside to the top of the furnace to feed it.

Air was blown into the furnace through three openings called tuyeres at the bottom. This air blast was created by a powerful steam engine. Water for the steam engine and other uses was pumped from the Moorabool River, which was 70 meters below the furnace.

The furnace mainly used charcoal as fuel. Charcoal was made from local timber, which was good because Lal Lal wood made strong charcoal that could support the heavy materials inside the furnace. Some coke (a fuel made from coal) was also brought in by train from Geelong and Ballarat.

Transporting Materials

The Geelong–Ballarat railway line was very important for the Lal Lal Iron Works. It was used to bring in limestone and coke, and to take the finished pig iron to Ballarat. For many years, getting materials between the Lal Lal railway siding and the furnace site was a big challenge. They relied on bullock wagons on bad roads, which meant the works had to close every winter.

Finally, around April 1884, a special tramway was built. This tramway was about 5.6 kilometers long and used horses to pull wagons. It made transporting materials much easier and allowed the iron works to operate all year round, though it was too late to save the business.

Quality of the Iron

Even though the Lal Lal furnaces used older technology, they could produce high-quality iron. This was partly because they used charcoal and the local iron ore was low in phosphorus and sulfur. The iron was known for being very strong and wear-resistant.

In 1878, the company's chairman proudly announced that Lal Lal iron had won a gold medal at the Paris Exhibition, competing against iron from all over the world. The company also showed its iron at big exhibitions in Sydney (1879) and Melbourne (1880). Many gold-mining companies in Victoria praised Lal Lal iron for its quality in making mining equipment like pipes and pumps.

What's Left Today

Today, the area where the mine and blast furnace operated is a public park called the Lal Lal-Bungal Historic Area. It's also where the Bungal Dam is located on the Western Moorabool River.

The most impressive thing left at the site is the ruin of the blast furnace built in 1880. You can still see its square base and the circular inner part of the upper furnace. Originally, the upper part also had an outer square stone casing, but that is now gone.

Near the furnace, you can also find the foundations where the machinery once stood. There's also a unique 'Cornish flue', which is a stone chimney built along the ground that rises with the hill. It was probably used to help clear smoke and bad gases away from the furnace area.

Downhill from the furnace, towards the river, there's a large pile of slag. Slag is the waste material left over after iron is made. You can also still see parts of the old tramway path, clearings where charcoal was burned, and areas where iron ore was mined.

Even though the Lal Lal blast furnace didn't last, its story shows the challenges of starting an iron industry in Australia a long time ago. It reminds us of the early efforts to make iron in Australia before larger, more successful iron and steel industries developed later on.

| Stephanie Wilson |

| Charles Bolden |

| Ronald McNair |

| Frederick D. Gregory |