Meadow River Lumber Company facts for kids

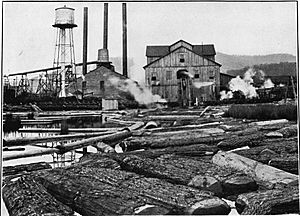

The Meadow River Lumber Company was a huge sawmill that operated in Rainelle, West Virginia. It was open from 1906 to 1975. This company was known as the biggest hardwood sawmill in the world!

Imagine this: it had three giant saws, each 9 feet (2.7 meters) tall, all working under one roof. At its busiest in 1928, about 500 people worked there. They produced a massive amount of lumber, enough to fill many trucks. They also cut down trees from about 3,000 acres (12 square kilometers) of untouched forest every year.

Contents

Company History and Growth

Starting the Sawmill

The story of the Meadow River Lumber Company began in 1903. Two brothers, Thomas and John Raine, from Ohio and Pennsylvania, joined a lumber business in Randolph County, West Virginia.

A few years later, in 1906, the brothers started buying a huge amount of land. They bought about 100,000 acres (400 square kilometers) in western Greenbrier County, West Virginia. This land had one of the last big areas of untouched hardwood trees in the United States. Most of these trees were near the Meadow River.

Building the Railroad

The land was about 20 miles (32 kilometers) from the nearest main railroad line. So, the Raine brothers first created the Sewell Valley Railroad Company. Their goal was to build a special train track, called a spur line.

This spur line later became the Meadow River Railroad. At first, it was used to bring building materials into the wild area. Later, it helped carry all the lumber products out to be sold.

First Boards and Big Saws

Construction on the sawmill started in 1909. The very first board was cut in September 1910. Eventually, the mill had three huge 9-foot (2.7-meter) bandsaws working under one roof. This made it the largest hardwood sawmill around.

The company also used special steam locomotives called Shay engines. These trains helped move logs and lumber. One of these engines was later moved to the Cass Scenic Railroad State Park in 1964.

Making Finished Wood Products

The plant also had a planing mill. This part of the factory could make a million feet (2.36 million cubic meters) of finished wood each year. This included things like flooring, ceiling panels, siding, and decorative trim.

To prepare the wood, six large kilns were used. Kilns are like big ovens that dry out the lumber. This drying process made the wood ready for the planing mill.

Storing Lumber

After the wood was cut and dried, it needed to be stored. The company had 10 long lumber docks, each about 1,300 feet (400 meters) long. Imagine 3 miles (4.8 kilometers) of lumber piles! Some of these piles were as tall as 40 feet (12 meters).

Creating a Company Town

In 1913, the company built the nearby town of Rainelle, West Virginia. The houses in Rainelle were owned by the company. They were built with modern plumbing and electricity. Inside, they had plaster and wallpaper. Outside, they were painted white. Each house also had its own yard and space for a garden.

Fire and Rebuilding

In 1924, the original mill building was destroyed by a fire. But the company didn't give up! All the employees worked together to build a new mill. It was ready and working again by March of the next year.

Changes in Logging and Products

In 1939, Meadow River lumber started using a method called clearcutting. This means cutting down all the trees in a certain area.

The main things the mill produced were flooring, hardwood shoe heels, and furniture. Later, they also made moldings and trim for houses. By the time the mill closed, it was the world's biggest maker of women's hardwood shoe heels and flooring. It was also the last big independent wood producer in the Eastern United States.

The business was sold to the Georgia-Pacific Corporation in 1970. The mill was then taken down in 1975.

| Dorothy Vaughan |

| Charles Henry Turner |

| Hildrus Poindexter |

| Henry Cecil McBay |