- This page was last modified on 17 October 2025, at 10:18. Suggest an edit.

OK Mine & Smelter facts for kids

| OK Mine & Smelter | |

|---|---|

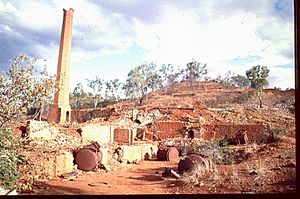

OK Mine & Smelter, 1994

|

|

| Location | Kitoba Holding, Bellevue, Shire of Mareeba, Queensland, Australia |

| Design period | 1900 - 1914 (early 20th century) |

| Built | 1902 - 1942 |

| Official name: OK Mine & Smelter | |

| Type | state heritage (built, archaeological) |

| Designated | 2 October 1996 |

| Reference no. | 601363 |

| Significant period | 1902-1910, 1930-1942 (fabric, historical) |

| Significant components | mine - open cut, wall/s - retaining, shaft, terracing, chimney/chimney stack, mounting block/stand, track, flue, slag pile/slag heap, machinery/plant/equipment - mining/mineral processing, tank - water, weighbridge/weigh station |

| Lua error in Module:Location_map at line 420: attempt to index field 'wikibase' (a nil value). | |

The OK Mine & Smelter is a historic mining site in Queensland, Australia. It was built between 1902 and 1942. This important site is now protected on the Queensland Heritage Register. It shows us how copper mining developed in North Queensland long ago.

Contents

A Mine's Story

Discovery and Early Days

In September 1901, a man named John Munro found copper in an area near Chillagoe. He called the place "OK," supposedly after an empty jam tin. In November 1902, Munro applied for a mining area where he found a lot of copper. Tests showed the copper was very pure, about 34%.

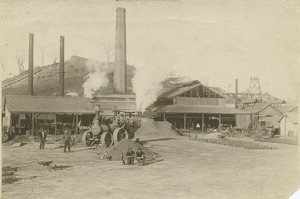

Soon after, the OK Copper Mines Development Syndicate NL was formed. This group included John Munro and other important people like railway builders and store owners. This syndicate worked hard to develop the mine. They also built and ran the OK smelters. They were the first copper company in North Queensland to make enough money to pay a dividend to their investors.

Getting the Copper Out

Moving the mined copper was a big challenge for mining companies. Luckily, a railway had just been finished to nearby Mungana. This railway made the OK mining project possible. It meant they could transport the copper more easily.

At first, the OK Syndicate hired about a dozen men. They mined the rich copper found close to the surface. This copper was then taken to Mount Garnet for smelting. A road was built to Mungana in August 1902. The first teams of workers used this road to carry copper ore to the Mungana railway station. From there, it went to the Mount Garnet smelters.

Building Their Own Smelter

The syndicate soon decided to build their own smelters. They bought the Mount Garnet smelters, which were no longer in use. The OK smelter cost about £5,000 and started working in November 1904. The company also built a storage building near the Walsh River for the wet season.

The smelter worked well, but not always continuously at first. This was until all the materials and transport plans were ready. They needed to move a lot of copper and bring in supplies like coke and limestone. At one point, a shareholder named Abdul Wade used about 400 camels for transport! But camels were expensive and caused problems. So, the company bought ten wood-burning engines to move things to and from Mungana.

Success and Challenges

By May 1905, the company had a lot of copper ready to sell. They believed they had a huge amount of ore still in the ground. In June 1905, they paid their first dividend to shareholders. This made them the first copper mining company in North Queensland to do so. In 1905, they produced copper worth over £61,000.

In 1906, they produced even more copper. They also bought new equipment like boilers and a new converter plant. They hired 250 men. In 1907, a tall, eight-sided brick chimney was built to help with smelter ventilation. An experienced engineer, Keith Maitland-Gibson, made the smelter even bigger that year. They added new furnaces and doubled the smelter's capacity.

However, the company's luck changed in 1908. The quality of the copper found got worse. They couldn't find much valuable ore below 150 feet deep. Copper production dropped. In October 1909, mining stopped because of a workers' strike. There were also disagreements among the company's directors.

The smelters closed in June 1910. The mine and town also shut down after a court case. The company was ordered to pay a large sum of money. Another big reason for closing was that the copper content in the ore was rapidly decreasing.

Later Years

After 1910, people tried to start a new company in 1912, but it didn't work. The mine was full of water and couldn't be used. The company sold its transport engines, which were then used in other mining and timber industries.

The First World War (1914-1918) caused big changes in metal prices. Copper prices first dropped, then soared as governments needed it for making weapons. This brought a few years of good times for copper mining. But after the war, prices fell sharply.

In 1920, a cyclone damaged the OK Mine buildings. There was a plan to process the leftover ore, but it didn't happen. Some machinery was even moved from the OK Mine to the Chillagoe State Smelters in 1921.

The mine opened again in 1930. It supplied copper to the Chillagoe smelters. It finally closed in 1942 after producing a total of 7,685 tons of copper. In 1951, the OK Syndicate tried again to process some ore, but it was a small effort.

What's Left Today

Today, you can still see the smelter works and the open-cut mine. They are located around a small hill.

The smelter site has four levels with stone walls. The lowest level, called the copper floor, still has some old machinery. This includes copper converter vessels and old steam engines. Above this, there's a long brick flue that leads to the tall, eight-sided brick chimney. The chimney is still standing, though it has some damage at the top, possibly from lightning.

A large pile of waste material, called a slag dump, stretches north from the main chimney for about 120 meters. It's very well preserved. You can also find an old steel weighbridge on a former access track. This weighbridge was used to weigh materials.

Southwest of the smelter are the mine workings. This includes a large open area with several mine shafts. You can also see stone water tanks above the smelter levels.

Why It's Important

The OK Mine & Smelter is important for several reasons:

- It shows how copper mining started and grew in North Queensland.

- The old steam engine reminds us of the challenges and costs of transporting ore long ago.

- It's a rare example of a mid-sized copper smelter layout.

- The large, neat slag dump is very unusual and well-preserved.

- The eight-sided brick chimney is one of only three like it in North Queensland.

- The Pooley and Sons weighbridge is the most complete and substantial one found in North Queensland.

- As a ruin, the site and its slag dump look very interesting and unique.

- The OK Copper Mines Development Syndicate NL was the first copper company in North Queensland to pay a dividend to its investors. This shows they were good at planning their work and spending money wisely. No other public company in that mining area achieved this.