Chillagoe smelters facts for kids

Quick facts for kids Chillagoe smelters |

|

|---|---|

Chillagoe Smelters, 2009

|

|

| Location | Chillagoe-Mungana Caves National Park, Mareeba Mining District, Chillagoe, Shire of Mareeba, Queensland, Australia |

| Design period | 1900 - 1914 (early 20th century) |

| Built | 1900 - 1910s |

| Official name: Chillagoe Smelters, Chillagoe State Smelters | |

| Type | state heritage (archaeological, built) |

| Designated | 21 October 1992 |

| Reference no. | 600675 |

| Significant period | 1900-1910s (fabric) 1901-1914, 1920-1943 (historical) |

| Significant components | embankment - railway, machinery/plant/equipment - mining/mineral processing, residential accommodation - housing, weir, slag pile/slag heap, flue, chimney/chimney stack |

| Lua error in Module:Location_map at line 420: attempt to index field 'wikibase' (a nil value). | |

The Chillagoe smelters are a special historical site in Queensland, Australia. They are located within the Chillagoe-Mungana Caves National Park. These smelters were like a giant factory that processed rocks (ore) to get valuable metals. They operated in the early 1900s and were also known as the Chillagoe State Smelters. This site is so important that it was added to the Queensland Heritage Register in 1992.

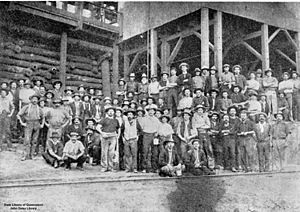

Back in their busiest days, the Chillagoe Smelters were the heart of a busy mining area. This industry brought a lot of growth and money to the Chillagoe region. By June 1901, a railway line was finished, and Chillagoe became a thriving town. The railway helped bring in the huge machines needed for the smelters. These machines started working by September 1901. The company that owned them, the Chillagoe Railway and Mining Company, used the most modern equipment. Nearby mines at Mungana, Zillmanton, and Redcap also worked on a large scale. At times, the mines, railway, and smelter employed up to 1,000 people!

The Chillagoe Smelter kept working until 1943. In its 40 years, it processed about 1.25 million tonnes of ore. From this, it produced 60,000 tonnes of copper, 50,000 tonnes of lead, 181 tonnes of silver, and 5 tonnes of gold. By 1943, new smelters were built closer to major mining areas like Mount Isa. It became too expensive to keep the state-run Chillagoe Smelter going. In 1950, the buildings and equipment were sold off. Today, the Queensland Parks and Wildlife Service looks after the site.

Contents

Discovering Chillagoe's Riches

The first explorer to visit the Chillagoe area was James Venture Mulligan in 1874. Later, in 1887, William Atherton started a cattle farm there. He built a timber house near Chillagoe Creek.

Early Mining Efforts

John Moffat sent the first group of prospectors to the area in 1887. They found many promising spots for mining. Serious mining began in 1892 at Muldiva. Moffat's company started producing silver there. However, the price of silver soon dropped, and their new smelter only worked for 18 months. Moffat then built smaller test smelters at Calcifer in 1894 and at Girofla (near Mungana) in 1896.

In 1896, Moffat wanted to raise a lot of money to develop the Chillagoe mining area. He saw how successful mines were becoming in other parts of Australia. He found a group of wealthy investors in Melbourne. They agreed to buy his mining rights. They also planned to build large smelting works. Plus, they would build a private railway over 150 kilometres long. This railway would connect the government railhead at Mareeba to the mines and smelter. A company called Chillagoe Proprietary Limited was formed. The Queensland Government approved their plans in 1897. They even gave the company special benefits.

Building the Smelters

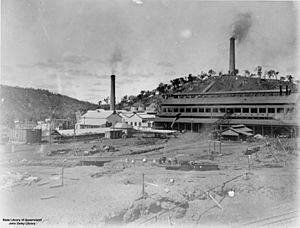

Construction of the smelter site began in mid-1900. The railway was also being built at the same time. Building the smelters was slow because all materials had to be brought overland. The railway finally reached Chillagoe in August 1901.

By mid-1900, the Chillagoe Company had many machines working. These included boilers, steam engines, pumps, and brick-making machines. Walkers Limited from Maryborough made the iron frames for the furnaces. By 1901, the site had even more equipment. This included more boilers, steam engines, and six furnaces. The total value of the equipment was over £23,000. J. M. Higgins and R. Shepherd, who had experience building other smelters, oversaw the construction. The plan was for the smelter to process 100 tonnes of ore each day.

Smelters Start and Face Challenges

The first six furnaces started working on October 13, 1902. But they didn't run smoothly. They only processed a small amount of ore. The works had to close down for the company to reorganise. A big problem was not having enough ore. They were only getting ore from Redcap and Calcifer. The company had hoped for ore from Mount Garnet too. Managers changed often in these early years.

In 1904, the Chillagoe smelter processed lead ore from the Girofla mine. It also processed ore from Torpy's Crooked Creek silver-lead mine. This produced a lot of lead and silver. In 1905, new converter machines were added.

In 1907, a new plant called the Huntingdon-Heberlein process plant was built. This cost £60,000. It involved breaking rocks and treating them to remove sulphur. Then the material went to the lead furnaces. A new electric plant was also installed.

A new lead furnace started in January 1908. However, many mines stopped working that year. This was due to higher wages and falling copper prices. A new copper furnace started in February 1908. The converter plant also worked well. The company could now process different types of ore. They could also treat waste material from other mines. To do this, they extended their tramline.

By 1909, the price of lead had dropped a lot. The Huntingdon-Heberlein plant had to be partly shut down.

A fourth blast furnace was added in 1909 to process copper ore. A bigger air-blowing machine also helped copper smelting. New electric motors and a centrifugal pump were installed. The area for testing ore samples was made twice as big.

In 1910, local ore supplies were low. So, ore was brought from far away to supply the Chillagoe smelters. Heavy rain in 1911 washed away railway bridges. This forced the smelters to close for a short time. The copper furnace was rebuilt in May 1911. A new machine for sintering (a process to prepare ore) was finished by November 1911. But a large part of the smelter was destroyed by fire. Luckily, the damage was quickly fixed, and it reopened in February 1912.

In May 1912, part of the main chimney's dust flue collapsed. It was rebuilt by June. The lead smelter closed down in early June, and 50 men lost their jobs. The copper smelter also closed due to a problem. Both furnaces reopened later that year.

In 1913, the smelters only worked sometimes. The company had financial problems. Also, workers wanted a shorter work week. Most importantly, the company was losing money. In February 1914, the company asked the Queensland Government for help. The Government refused, and the smelters closed immediately. They stayed closed from March 1914 until January 1920. This was during World War I, when metal prices were very high. Other copper smelters made a lot of money, but Chillagoe was closed.

The State Takes Over

In 1915, the Chillagoe Company offered to sell the railway to the Queensland Government. By Christmas, the Government found a way to fund upgrades for the smelters and mines. An agreement was made for the government to buy the railway, smelters, and mines. This agreement was passed by Parliament in November 1918. The government paid £661,000 for the railway, £30,000 for the smelters, and smaller amounts for the mines and machinery.

Peter Goddard was appointed Manager of the Chillagoe smelters in 1919. The smelters were managed by the Minister for Mines.

Smelting started again in January 1920. One copper and one lead furnace were working. The smelters ran steadily for seven years. They got copper ore from the Einasleigh mine and lead ore from the Girofla mine at Mungana. But metal prices continued to fall.

The State bought the Mungana mines in 1922. This helped secure ore supplies for the smelter. In 1921, the last remaining part of the old Chillagoe Company, the Mount Mulligan coal mine, closed. This happened after an underground explosion killed 75 miners. The State later bought this coal mine.

Ore supplies remained a challenge after the Einasleigh mine closed in 1922. Ore had to be brought by railway from many different places across North Queensland.

The 1920s were a time of discussion and concern about the smelters. A government investigation was set up in 1929 to look into the operations of the Chillagoe smelter and mines. The smelters reopened in October 1929 while this investigation was happening.

Despite not making much money, the smelters continued to operate. In 1932, Chillagoe produced its highest amount of copper ever, over 3,000 tonnes. But 1933 was the last year they produced lead. The cost of coke (fuel for the smelters) went down after 1933. This was when the Bowen State coke works opened. But it wasn't enough to make up for falling copper prices.

The Chillagoe State smelters were kept running to provide jobs in the mining areas. This was especially important during tough economic times.

The Final Closure

World War II caused metal prices to rise. In 1942, the Australian Government reviewed metal production. The Chillagoe smelters were not doing well. They were old, losing money every year, and working at a low capacity. More than half their ore came from far away. So, the government decided to close them. Mount Isa Mines was told to start producing copper instead. The Chillagoe smelters closed for the last time in July 1943.

By the time they closed, the smelters had lost a lot of money. The equipment and machinery were sold off. Small machines went to the Collinsville State Coal Mine. Bricks were sold to private buyers. Parts of the smelters were taken apart in 1949 and sent to other government operations. The Queensland Government officially wrote off the remaining debt in 1954.

Since then, the site has been used for collecting slag (waste material) for railway tracks. Since the 1970s, tourists have also visited the site.

The Chillagoe smelters produced copper for 37 years between 1901 and 1943. They produced lead for 25 of those years. In total, they processed about 1.25 million tonnes of ore. They produced 60,000 tonnes of copper, 50,000 tonnes of lead, 6.5 million ounces of silver, and 175,000 ounces of gold. At least 1 million tonnes of slag were left behind. The Chillagoe smelters never made a profit. They probably lost their owners between £4 million and £5 million in total.

What Remains Today

The main smelter area still has the steel supports for two blast furnaces. You can also see where two more furnaces once stood. A large brick flue (a channel for smoke) goes up the hill to the main smelter chimney. This tall, round brick chimney is a key feature of the site and the town. The top of this chimney has been damaged by lightning.

Next to the main smelter area are the foundations of the power house, workshops, and water softener plant. The power house chimney is octagonal and is the most complete of the three brick chimneys at the site. Its top has been made stable to help preserve it. Near the blast furnace site, there's also a furnace for reheating metal and four converters.

The area where lead sulphide was prepared has furnace foundations and plant remains. This includes a Dwight-Lloyd sintering plant and Edwards roasters. There's also a third brick chimney, called the roaster chimney, which is round. Remains of a crusher are next to it.

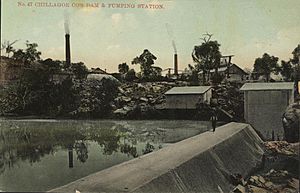

From the smelter areas, a large slag dump stretches eastward to Chillagoe Creek. A concrete weir (a small dam) and the foundations of a pump house are on the creek. You can also find evidence of where smelter workers used to live across the creek. One family house still stands there. Railway tracks and earth mounds extend west from the smelter areas. The foundations of an assay office (for testing metals), general office, stores, weighbridge, and railway workshops are also in this area.

Some of the remaining equipment includes:

- Primary crusher parts

- No 5 Gates Gyratory Breaker & Krupp rolls

- 4 Copper converter vessels

- Blast furnace steel mounts from Walkers Ltd.

- 3 Blast furnace vats (not in their original places)

- Virginia firebricks

- Roaster chimney

- Huntington Heberlein plant

Why the Smelters are Important

The Chillagoe Smelters are very important to Queensland's history. They show how mining grew in North Queensland from 1870 to 1914. For much of the time from 1901 to 1943, the Chillagoe smelters were a big part of the economy in the Cairns area.

Even though the company never made a profit, the smelters created thousands of jobs. They also provided railway transport over huge distances. This helped keep mines and businesses open across the north. The smelters helped North Queensland's economy for almost 50 years. In their later years, the government even ran them at a loss to keep this economic role going.

The site also shows rare and special smelting processes. The three tall brick chimneys that remain are unique as a group. The slag dump is the largest one left in Queensland.

The Chillagoe smelters are a great example of how metals like copper, silver, lead, and gold were processed around 1900. Modern equipment was brought in and changed over time to fit local conditions.

The smelters are also connected to important people in Queensland's history. These include mining leaders John Moffat and J. S. Reid. They are also linked to the political careers of William McCormack and Edward Theodore.

Images for kids