Quincy Mine No. 2 Shaft Hoist House facts for kids

|

Quincy Mine No. 2 Shaft Hoist House

|

|

|

U.S. Historic district

Contributing property |

|

No. 2 Shaft Hoist House in 2009, on left. (Old hoist house is on right)

|

|

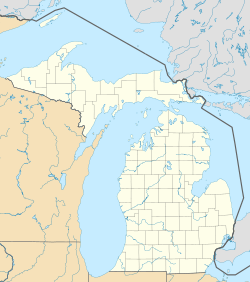

| Location | Franklin Township, Houghton County, Michigan |

|---|---|

| Nearest city | Hancock, Michigan |

| Area | 9 acres (3.6 ha) |

| Built | 1918 |

| Part of | Quincy Mining Company Historic District (ID89001095) |

| NRHP reference No. | 70000271 |

Quick facts for kids Significant dates |

|

| Added to NRHP | February 16, 1970 |

| Designated CP | February 10, 1989 |

The Quincy Mine No. 2 Shaft Hoist House is a very important old building. It is located north of Hancock, Michigan, along US Highway 41. This building is part of the Quincy Mining Company Historic District.

Inside the Hoist House, you'll find the largest steam-powered hoisting engine in the world. This giant machine sits on the biggest reinforced concrete foundation ever poured for an engine. The Hoist House was named a Michigan State Historic Site in 1969. It was also added to the National Register of Historic Places in 1970.

Contents

A Look Back: The Quincy Mine Story

The Quincy Mining Company was first started in 1846. It became an official company two years later. Its goal was to dig for copper in the Portage Lake area, where copper had recently been found.

Finding Copper and Success

It took a while for the mine to find its most productive copper deposit. This happened in 1856. The company didn't pay its first dividend (a payment to investors) until 1862.

However, after that, the Quincy Mine became a very good investment. It paid dividends every year from 1867 all the way until 1921.

The Need for a Bigger Hoist

In the early 1900s, the mine shafts at Quincy Mine were getting deeper and deeper. The company was digging further underground to find more copper. Between 1905 and 1920, the main shafts grew from 5,000 feet deep to over 7,000 feet.

Lifting rock to the surface from such great depths became very difficult. The old mine hoist equipment couldn't handle the strain. By 1916, the hoist for the number 2 shaft had reached its limit.

Instead of giving up on the shaft, Quincy decided to get a new, much stronger hoist. They hired the Nordberg Manufacturing Company and Bruno V. Nordberg to design it. This new engine cost $160,000 and would be the largest mine hoist in the world.

Building the Hoist House

Quincy ordered the Nordberg engine in early 1917. But World War I caused delays, and the engine didn't arrive until late 1919.

While waiting, a special building was designed for the hoist by J. H. Hoff. The McLean Construction Company of Chicago built it. The foundation cost $43,000, and the main building cost $53,000. The Hoist House was mostly finished in 1918.

Hoist Installation and Operation

Installation of the huge hoist began in December 1919. It took almost a year, finally becoming fully ready in November 1920. The extra cost to install the hoist was $34,000.

The total cost for the building, engine, installation, and other parts was $370,000. The hoist worked from 1920 until the mine closed in 1931. The mine closed because copper prices fell too low.

Today, the building and hoist have been restored. They are open for people to visit and learn about.

What the Hoist House Looks Like

The Quincy Mine No. 2 Shaft Hoist House is a rectangular building. It is covered with red brick. The building measures 72 feet by 76 feet and is almost five stories tall.

Special Design Features

This building is quite fancy for a hoist house. It has many windows. It originally had a green glazed tile roof, but this was removed by 1978.

The building's design included very large doors. It also had a wide-open space inside with no columns. This made it easy to install the huge hoist using an overhead crane.

The Giant Foundation

The reinforced concrete foundation that supports the building and the hoist engine is truly amazing. It contains 32,000 cubic yards of material. People say it was the largest block of reinforced concrete ever poured for such a purpose. It was also one of the first very large reinforced concrete buildings ever constructed.

The Hoist Machine Itself

The hoist machine inside is enormous. It measures 60 feet by 54 feet. It weighs a massive 1,765,000 pounds! This powerful machine could pull a skip (a large bucket) holding 20,000 pounds of rock. It could do this at a speed of 36.4 miles per hour.

Images for kids

| Precious Adams |

| Lauren Anderson |

| Janet Collins |