Quincy Mine facts for kids

|

Quincy Mining Company

Historic District |

|

The #2 Shafthouse (left) and the Hoist House (right)

|

|

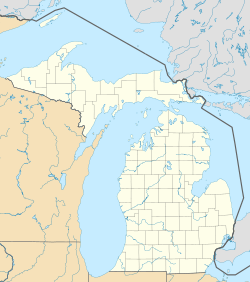

| Location | Franklin Township, Houghton County, Michigan |

|---|---|

| Nearest city | Hancock, Michigan |

| Area | 779 acres (3.15 km2) |

| Architect | Quincy Mining Co. |

| NRHP reference No. | 89001095 |

Quick facts for kids Significant dates |

|

| Added to NRHP | February 10, 1989 |

| Designated NHLD | February 10, 1989 |

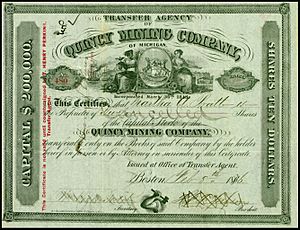

The Quincy Mine is a large set of copper mines located near Hancock, Michigan. The mine was owned by the Quincy Mining Company. It operated from 1846 to 1945, though some work continued into the 1970s. The Quincy Mine was known as "Old Reliable." This was because the company paid money to its investors every year from 1868 to 1920. The Quincy Mining Company Historic District is a special place in the United States. It is recognized as a National Historic Landmark District. Other Quincy Mine properties nearby are also important. These include the Quincy Mining Company Stamp Mills, the Quincy Dredge Number Two, and the Quincy Smelter.

Contents

The Story of Quincy Mine

The Quincy Mine started in 1846. Two companies, Northwest Mining Company and Portage Mining Company, joined together. They had both bought the same land by mistake. This happened during a time when many people were looking for copper. The company leaders decided to merge. They received a lot of money from Massachusetts. The town of Quincy, Massachusetts gave the mine its name. Many other copper mines started at the same time. But Quincy Mine became the most successful one from the 1840s. It was the country's top copper producer from 1863 to 1867.

How Quincy Mine Found Copper

The Quincy Mine was the first in Michigan to change how it mined copper. At first, they used "fissure mining." This meant finding large, pure pieces of copper in cracks in the rock. These pieces were hard to get out and cost a lot of money. In 1856, they found a new way called "amygdaloid mining." This involved finding smaller pieces of copper spread out in certain rock layers. These layers were easier to blast out. The rock could then be processed somewhere else. This new method was much cheaper and produced more copper.

The Pewabic copper deposit was very rich. It allowed the Quincy Mine to make money for 53 years in a row. The company grew by buying nearby properties. They bought the Pewabic mine in 1891. They also bought the Mesnard and Pontiac mines in 1897. In 1908, they bought the Franklin mine. This helped Quincy Mine last longer than almost all other copper mines in the Keweenaw Peninsula. Only the Calumet and Hecla Mining Company and the Copper Range Company lasted longer.

Housing for Miners

The Quincy Mining Company wanted to attract good workers. So, they built and took care of homes for them. In the early days, workers lived in simple tents. Later, the company built full three-story houses. The company leaders wanted to build nice homes. They wanted homes with things like electricity and running water. This was to make workers happy and keep them from leaving. This plan worked well. It helped Quincy Mining Company stay a top mining company.

Mine Closure

The Quincy Mining Company stopped mining in 1931. This was because copper prices were very low. During World War II, the mines opened again. This was because more copper was needed for the war. After the war, the government stopped supporting copper prices. The mines then closed for good.

Amazing Engineering at the Mine

When the mine closed in 1945, the Quincy Number 2 shaft was the world's longest mine shaft. It went down 9,260 feet (about 2.8 kilometers) at an angle. To move ore and workers in this deep shaft, the world's largest steam-powered mine hoist was built. It was finished in 1918. This huge machine was housed in the Quincy Number 2 Hoist House.

The Nordberg Steam Hoist and its building cost over $370,000 in 1918. The building was made of strong concrete with brick on the outside. It had fancy Italian-tiled walls. The hoist weighed more than 880 tons. It could lift 10 tons of ore at 36.4 miles per hour. This saved a lot of money on fuel. The hoist sat on the largest concrete base ever poured at that time. The Number 2 Hoist House was very decorative. It was used to impress visitors and investors.

The Mine Today

Today, the Quincy Mine is a popular place to visit in the Keweenaw Peninsula. The Quincy Mine Hoist Association takes care of the buildings and grounds. They offer tours of the Number 2 Hoist House. You can also visit the 7th level of the mine during the summer. Visitors ride to the 7th level on the Quincy and Torch Lake Cog Railway. Many buildings have museum exhibits. The mine and nearby areas are part of Keweenaw National Historical Park.

Two old trains from the Quincy & Torch Lake Railroad are still on site. These trains used to carry ore from the mine to a processing mill. One is Locomotive #1, called the Thomas F. Mason. The other is Locomotive #6, which was the last engine bought for the line in 1913.

The shafts and tunnels of the Quincy Mine have slowly filled with groundwater since it closed. The water now reaches up to the seventh level. This means all lower levels cannot be reached. The seventh level is drained by a large tunnel called an adit. This adit is also the entrance for mine tours.

See also

- Copper mining in Michigan

- Copper Country Strike of 1913-1914

- Underground mining (hard rock)