Quincy Smelter facts for kids

Quick facts for kids |

|

|

Quincy Smelter

|

|

|

U.S. National Historic Landmark District

Contributing Property |

|

Quincy Smelter site in July 2008

|

|

| Location | Ripley, Michigan |

|---|---|

| NRHP reference No. | 89001095 |

| Added to NRHP | February 10, 1989 |

The Quincy Smelter, also known as the Quincy Smelting Works, was a place where copper was melted and purified. It is located in Ripley, Michigan, on the north side of the Keweenaw Waterway. This smelter is an important part of the Quincy Mining Company Historic District, which is a special historical site.

The Quincy Mining Company built the smelter in 1898. It was used to process copper from 1898 to 1931, and then again from 1948 to 1971. For many years, from 1986 to 2013, the smelter site was part of a Superfund cleanup project. This meant the government worked to clean up any pollution there.

Contents

History of the Smelter

How the Smelter Operated

The Quincy Mining Company started in 1848. Like other mines, Quincy had its own stamp mills. These mills crushed the copper rock. However, Quincy did not have enough copper at first to build its own smelter. Before 1860, copper was sent to cities like Boston or Detroit to be melted. Later, the Lake Superior Smelter opened closer by in Hancock.

By the late 1890s, the Quincy Mine was producing a lot more copper. This made it worthwhile for the company to build its own smelter. In May 1898, construction of the Quincy Smelter began. It was built on the old waste sands from the Pewabic mill. Quincy had bought the Pewabic Mining Company in 1891.

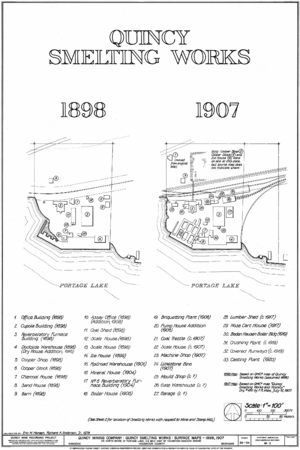

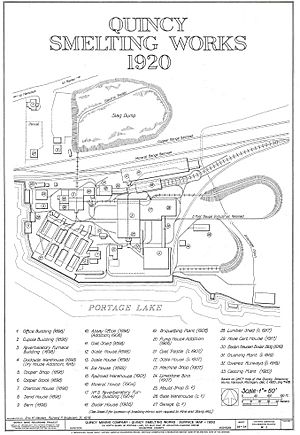

Workers dug out the shoreline and put in strong poles for a loading dock. Then, they built the main smelter buildings. These included the reverberatory furnace building and the cupola furnace building. By the end of 1898, more than a dozen buildings were ready. The smelter started working on December 1, 1898. It was estimated to save the Quincy Mining Company about $100,000 each year.

The Quincy Smelter processed copper not only from the Quincy Mine. It also worked with other mines like Franklin and Adventure.

Changes Over Time

Due to low copper prices and the start of the Great Depression (a time of great economic hardship), the Quincy Mining Company stopped working on September 22, 1931. The smelter was closed down. The mine itself stayed closed until 1937, when copper prices went up. Instead of reopening the Quincy Smelter, another company, Calumet and Hecla, handled the smelting.

During World War II, copper prices stayed high. In 1942, Quincy built a special plant on Torch Lake. This plant was designed to get copper from the large piles of leftover rock, called tailings, in the lake. The plant started in 1943. It used a floating machine that sucked up the tailings from the lake.

After the war, copper prices dropped again. The mine closed permanently in 1945. However, the copper recovery project from the lake continued. It was very successful and cheaper than mining new copper.

In June 1948, the Quincy Smelter reopened. This happened because Calumet and Hecla could no longer handle all of Quincy's copper. Around the same time, the Copper Range Company closed its own smelter. They then sent their copper to Quincy to be processed. The reclamation project on Torch Lake continued. In 1967, the last of the old copper sands in the lake were used up.

In 1968, new burners were added to one of the furnaces. These were used to melt scrap copper until 1971. In 1971, new rules from Michigan about protecting the environment were put in place. Because of these rules, Quincy stopped using the smelter. Ownership was then given to the Quincy Development Corporation.

After the Smelter Closed

In 1986, the Environmental Protection Agency (EPA) added the Torch Lake area to its Superfund list. This meant the area, including the Quincy Smelter, needed a big cleanup.

In 1999, Franklin Township took over the smelter from the Quincy Development Corporation.

In 2004, the EPA started cleaning up the smelter site. They removed old lab chemicals and checked for asbestos, a material that can be harmful. An 8-foot-tall fence was built around the site. Rocks, called riprap, were added to protect the shoreline. In 2008, all the remaining asbestos was removed from twelve buildings. One tall smokestack was also taken down because it was unsafe.

Public tours of the smelter began around 2009. At first, people could not go inside the buildings. This was because of pollution and safety concerns.

The Quincy Smelter was officially removed from the Superfund list in 2013. This meant the main cleanup was complete.

In 2014, the Keweenaw National Historical Park Advisory Commission bought the smelter. They bought it from Franklin Township.

In late 2015, an old ice house was taken down. It was affecting the water quality in the ground nearby.

Special Historical Status

The Quincy Smelter is the only copper smelter left in the United States from the early 1900s. The EPA calls it the "best preserved copper smelter" in the country. The Keweenaw National Historical Park Advisory Commission thinks it might be the only one of its kind left in the world.

On February 10, 1989, the Quincy Mining Company Historic District became a National Historic Landmark District. This means it is a very important historical place. The smelter is also part of the Keweenaw National Historical Park.

In 2016, ASM International, a group for materials scientists, named the Quincy Smelter an ASM Historical Landmark.

Smelter Buildings and Layout

The Quincy Smelter site sticks out into the Keweenaw Waterway. It was built on the old waste sands from the Pewabic mill. The smelter has two docks. One was a 350-foot-long shipping dock for copper. The other was a 250-foot-long dock for coal deliveries.

Most of the smelter buildings are made from a type of rock called Jacobsville Sandstone.

See also

- List of Copper Country smelters

- List of Superfund sites in Michigan

| William Lucy |

| Charles Hayes |

| Cleveland Robinson |