Rotating furnace facts for kids

A rotating furnace is a special machine that helps create objects with a unique curved shape called a paraboloid. These objects usually have a surface that curves inward, like a bowl. Most of the time, these objects are made from glass.

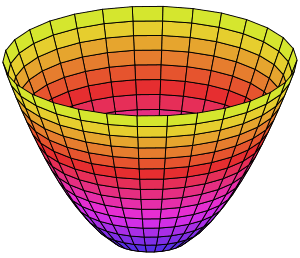

The furnace works because of a cool science fact: when a liquid spins, its surface naturally forms a concave paraboloid shape. This was something even Newton knew a long time ago! This natural shape is exactly what's needed for the main mirror of a reflecting telescope.

Paraboloids are very useful. When they are coated with a shiny material like silver, they can become primary mirrors in reflecting telescopes. They are also used in solar cookers to focus sunlight and create heat.

How a Rotating Furnace Works

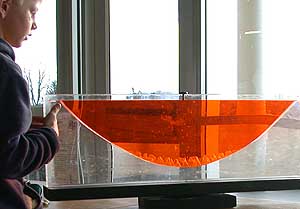

A rotating furnace has a container that spins very steadily around a straight up-and-down (vertical) axis. To make a mirror, enough glass is placed into this container. The glass is then heated until it melts completely and becomes a liquid.

While the glass is still spinning, it's allowed to cool down. It keeps spinning until it becomes completely solid again. When the spinning stops, the glass is solid, and its top surface has kept the perfect paraboloid shape. This special way of making things is called spin casting.

Making Lenses with Spin Casting

This same method can also be used to create a lens with a concave paraboloid surface. The bottom part of the lens gets its shape from the container holding the molten glass, which acts like a mold. Lenses made this way are sometimes used as objectives in refracting telescopes.

Creating Different Paraboloid Shapes

The center of the spinning motion becomes the center of the paraboloid shape. It's not always necessary for this spinning center to be right in the middle of the glass container. You can place the container away from the center of rotation. This allows you to create special "off-axis" paraboloid segments. This technique is important for making very large telescopes, which often have mirrors made from several different segments joined together.

| Anna J. Cooper |

| Mary McLeod Bethune |

| Lillie Mae Bradford |