Smokeless powder facts for kids

Smokeless powder is a special type of propellant used in firearms and artillery. It gets its name because it makes much less smoke when fired compared to older black powder. It also leaves less fouling (dirty residue) inside the gun barrel. Because they are used for similar things, both black powder and smokeless powder are often just called "gunpowder."

When smokeless powder burns, it mostly turns into gas. Black powder, however, leaves behind about 55% solid stuff. These solids can make the gun barrel rusty because they attract moisture. Smokeless powder doesn't have this problem.

Even though it's called "smokeless," it's not completely smoke-free. Small guns might not make much smoke. But big artillery guns can still produce a lot of smoke.

A French inventor named Paul Vieille created smokeless powder in 1884. Most modern smokeless powders are made from nitrocellulose. This material was found to be much better than other mixtures used in the late 1800s.

Smokeless powder is usually classified as an explosive. But when used normally, it burns very fast (called deflagration) instead of exploding instantly (called detonation). This controlled burning is what pushes a bullet or shell out of a gun.

Smokeless powder made it possible to create modern guns that load themselves, like semi-automatic and fully automatic firearms. These guns would get jammed easily with black powder's heavy residue. It also allowed for lighter parts in artillery guns.

Contents

History of Smokeless Powder

Before smokeless powder, using black powder caused many problems in battles. Military leaders during the Napoleonic Wars found it hard to give orders. The battlefield was often covered in thick smoke from the guns. It was also hard to see signals through the smoke.

After just a few shots, soldiers would have their view blocked by huge clouds of smoke. Snipers could not hide their positions. Black powder also burned less efficiently. It was only about one-third as powerful as the same amount of smokeless powder.

Black powder left a lot of solid residue. This residue attracted moisture from the air. Guns had to be cleaned after every use to stop rust. The residue also caused breech-loading guns to jam. This made reloading very difficult.

Early Explosives: Nitroglycerine and Guncotton

In 1847, an Italian chemist named Ascanio Sobrero created nitroglycerine. Later, Alfred Nobel developed it into an industrial explosive called "Dynamite." But nitroglycerine was not good for guns. It exploded too fast, which could shatter a gun barrel. It was also very sensitive to shocks. This made it unsafe to carry in battle.

A big step forward was the invention of guncotton in 1846. A German chemist, Christian Friedrich Schönbein, made this material from nitrocellulose. Guncotton was more powerful than black powder. But it was also more unstable.

An explosion destroyed a guncotton factory in England in 1847. Austrian factories also blew up. Guncotton was too dangerous for field use. Guns that could fire thousands of shots with black powder would wear out after only a few hundred shots with guncotton. Small guns could not handle the high pressures it created.

Later, a British chemist named Sir Frederick Abel found a way to make guncotton safer. He removed impurities from nitrocellulose. This made it more stable and safer to handle. His process was patented in 1865.

Big Improvements in Powder

In 1863, a Prussian artillery captain named Johann F. E. Schultze patented a new powder. It was made from nitrated wood. Other inventors also worked on new powders. But many of these early smokeless powders were only good for shotguns, not rifles. Rifles create more resistance to gas expansion.

In 1884, Paul Vieille invented a truly revolutionary smokeless powder. He called it Poudre B (meaning "white powder"). It was made from different types of nitrocellulose. This powder was rolled into thin sheets and cut into flakes.

Vieille's powder was amazing for small guns. It made almost no smoke. It was also three times more powerful than black powder. This meant bullets flew faster and straighter. Soldiers could hit targets from 1,000 m (1,094 yd) away. Less powder was needed per bullet. This made cartridges smaller and lighter. Soldiers could carry more ammunition. Poudre B could even burn when wet, unlike black powder.

Other European countries quickly started making their own versions of Poudre B. Germany and Austria introduced new weapons in 1888. Later, chemicals like diphenylamine were added to make the powder more stable.

In 1887, Alfred Nobel patented his own smokeless powder called Ballistite. This powder used nitroglycerine to dissolve the nitrocellulose. Other inventors, like Hiram Maxim and Hudson Maxim, also patented similar powders.

Britain wanted an even better powder. In 1889, Sir Frederick Abel, James Dewar, and Dr. W. Kellner patented a new formula. It was called Cordite. Cordite became widely used by the British military in 1891. It was made of nitroglycerine, guncotton, and mineral jelly. Cordite could be made in any shape or size. It also caused less wear on gun barrels.

Many companies in the United States also started making smokeless powder. By the early 1900s, DuPont became a major producer. Newer powders were more stable and safer to handle than the first ones.

How Smokeless Powder Works

The way smokeless powder burns depends a lot on the size and shape of its pieces. Powder only burns on its surface. So, larger pieces burn more slowly. Some powders also have special coatings to slow down the burning even more.

The goal is to control how fast the powder burns. This creates a steady pressure that pushes the bullet down the barrel. This helps the bullet go as fast as possible. For example, fast-burning pistol powders are often made as flakes or flattened beads.

Smokeless powder does not leave the thick, sticky residue that black powder does. This means gun barrels don't rust as easily. (Some older primer compounds could leave salts that caused rust, but non-corrosive primers were invented in the 1920s.)

Faster-burning powders create higher temperatures and pressures. But they also cause more wear on gun barrels.

Over time, nitrocellulose can break down. This creates acidic byproducts. These acids can speed up the breakdown even more. If a lot of powder is stored together, the heat from this breakdown can even cause it to catch fire. To stop this, special chemicals called stabilizers are added to the powder. These stabilizers help keep the powder safe for a long time.

What Smokeless Powder is Made Of

Smokeless powders are made from different ingredients. These ingredients affect how the powder burns and how powerful it is.

- Single-base powder uses only nitrocellulose as its main explosive ingredient. Nitrocellulose is often mixed with ether and alcohol.

- Double-base powder contains both nitrocellulose and nitroglycerin. Sometimes, diethylene glycol dinitrate is used instead of nitroglycerin. This can help reduce the heat of the flame without losing power. Less heat means less wear on the gun barrel.

- Triple-base propellant was developed in the 1930s. It has nitrocellulose, nitroglycerin (or diethylene glycol dinitrate), and a good amount of nitroguanidine. These powders are called "cold propellants." They produce less flash and heat, but still give good pressure. They are mainly used for large guns, like those on ships or tanks, because these guns wear out quickly.

Newer powders are also being developed. Some of these use nitroguanidine and other powerful explosives like RDX.

Other ingredients are added to smokeless powder for different reasons:

- Deterrents (or moderants) slow down the burning rate. Examples include centralites and dibutyl phthalate.

- Stabilizers prevent the powder from breaking down over time. Diphenylamine is a common one.

- Decoppering additives stop copper from building up in the gun barrel. Copper comes from the bullet jacket. Tin and bismuth compounds are used for this.

- Wear reduction materials like wax or titanium dioxide are added to protect the gun barrel.

- Other additives include solvents (like ethyl acetate), rosin (to hold grain shape), and graphite. Graphite helps prevent static electricity and makes the powder flow better.

Reducing Muzzle Flash

Muzzle flash is the bright light seen at the end of a gun barrel when it fires. It comes from the hot gases and chemical reactions as the gases mix with air. This flash can be a problem, especially at night. It can show the enemy where the gun is. It can also temporarily blind the gun crew.

Smokeless powder doesn't have enough oxygen to burn completely on its own. So, when the hot gases leave the barrel, they mix with oxygen in the air and can ignite. This causes the bright secondary flash.

On small guns, special devices called flash suppressors can reduce the flash. But for large artillery, this isn't practical. For artillery, the best way is to use a powder that produces a lot of inert nitrogen gas at lower temperatures. This nitrogen dilutes the flammable gases. Triple-base propellants are good for this because they contain nitrogen.

Flash reducers like potassium chloride or potassium nitrate can also be added. They help cool the gases and block visible light. However, all flash reducers have one downside: they produce more smoke.

How Smokeless Powder is Made

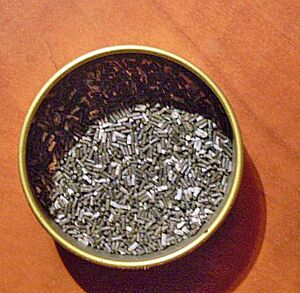

Smokeless powder can be made into small round balls. Or it can be pushed through a machine (called extrusion) to make cylinders or strips. These pieces can have many different shapes, like single-hole cylinders or slotted cylinders. They are then cut into short "flakes" or long "cords." Powder for cannons usually has the largest pieces.

The process starts with short cotton fibers. These fibers are cleaned and then turned into nitrocellulose using strong acids. At this stage, the nitrocellulose still looks like cotton. It's often called pyrocellulose.

Next, any leftover acid is washed away. Then, alcohol removes the water. The nitrocellulose is mixed with ether and a stabilizer like diphenylamine. This mixture is then pushed through a press to form long cords or tubes. These are cut into the right length.

The alcohol and ether are then evaporated from the powder pieces. The pieces are coated with electrically conductive graphite. This stops static electricity from causing accidental fires. Large batches of powder are mixed together to make sure they all burn the same way. Each batch is tested to find out how much powder is needed for a specific gun.

Sometimes, old military smokeless powder is recycled to make new batches. In the 1930s, a process was developed to make spherical (round) smokeless powder. This involves dissolving the powder in a liquid, then heating and stirring it with water until small spheres form. These spheres can then be changed further. For example, nitroglycerine can be added to increase energy. They can also be flattened or coated to control burning.

Today, smokeless powder in the United States is produced by St. Marks Powder, Inc.

See also

- Antique firearms

- Brown-brown

| Kyle Baker |

| Joseph Yoakum |

| Laura Wheeler Waring |

| Henry Ossawa Tanner |