Through-hole technology facts for kids

Through-hole technology is a way to connect electronic parts to a special board called a printed circuit board (PCB). Think of a PCB as the "brain" or "nervous system" of an electronic device, where all the parts are connected.

This method uses small wires, called leads, that stick out from the electronic parts. These leads are pushed through tiny holes drilled into the PCB. Once the leads are through, they are attached to the board using a melted metal called solder. This can be done by hand or by special machines.

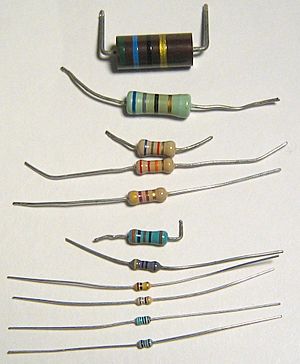

Many electronic parts made with through-hole technology are bigger than those made with a newer method called surface-mount technology.

Contents

How Through-Hole Technology Works

When you look at an electronic part made for through-hole technology, you'll see it has metal wires or "legs" sticking out. These legs are very important!

First, tiny holes are carefully drilled into the printed circuit board. These holes are just the right size for the part's legs to fit through.

Next, the electronic part is placed on the board. Its legs go all the way through the holes to the other side. On the other side of the board, there are metal pads around each hole.

Finally, the legs are connected to these pads using solder. Solder is a special metal that melts easily. When it cools, it becomes hard and creates a strong electrical connection. This connection holds the part firmly in place and lets electricity flow through it.

Why Through-Hole Is Still Used

Even though newer technologies exist, through-hole parts are still very useful for many reasons.

- Strong Connections: The way through-hole parts are mounted makes them very strong. They are less likely to break off the board if the device is dropped or shaken. This is why you might find them in things that need to be tough, like industrial machines or older electronics.

- Easy to Fix: If a through-hole part breaks, it's often easier to remove and replace it. People who fix electronics or enjoy building their own projects often prefer through-hole because it's simpler to work with by hand.

- Prototyping and Learning: For students and hobbyists learning about electronics, through-hole parts are great. They are larger and easier to handle, making it simpler to build and test new ideas or learn how circuits work.

- High Power: Some electronic parts that handle a lot of power or heat are often made with through-hole technology. Their larger size helps them manage the heat better.

Through-Hole vs. Surface Mount

You might hear about another way to put parts on a PCB called surface-mount technology (SMT). Here's how they are different:

- Size: Through-hole parts are generally bigger. SMT parts are much smaller and sit right on the surface of the board, without needing holes to go through.

- Assembly: Through-hole parts are inserted into holes. SMT parts are placed directly onto pads on the surface of the board and then soldered.

- Density: Because SMT parts are so tiny, many more of them can fit on a single circuit board. This allows for smaller and more complex electronic devices, like smartphones.

- Manufacturing: SMT is often used for mass production because machines can place tiny parts very quickly. Through-hole can be done by hand or machine, but it's often slower for very large numbers of parts.

Both technologies have their own strengths and are used for different kinds of electronic devices today.

Images for kids

-

Through-hole devices mounted on the circuit board of a mid-1980s home computer. You can see different types of parts here.

-

Parts like integrated circuits can have many leads, sometimes dozens!

See also

In Spanish: Tecnología de agujeros pasantes para niños

In Spanish: Tecnología de agujeros pasantes para niños