Surface-mount technology facts for kids

Surface-mount technology (SMT) is a way to build electronic devices. It uses tiny electronic parts that are placed right onto the surface of a printed circuit board (PCB). Think of a PCB as the green board inside your phone or computer.

These tiny parts are called surface-mount devices (SMDs). They are much smaller than older electronic parts. Older parts, called "through-hole" parts, have long wires that go through holes in the circuit board. SMDs don't need these holes, making devices smaller and easier to make.

Contents

What is Surface-Mount Technology?

Surface-mount technology helps make electronic gadgets smaller and faster. Instead of poking wires through holes, SMDs are soldered directly onto the flat surface of a circuit board. This saves space and lets manufacturers pack more parts onto a board.

Why Use SMT?

- Smaller Devices: SMDs are tiny, so products like smartphones and smartwatches can be very compact.

- Faster Production: Machines can place SMDs very quickly, making it faster to build many electronic items.

- Better Performance: Because the parts are closer together, signals travel faster, which can make devices work better.

- Lower Cost: Making many devices with SMT can be cheaper in the long run.

Common Surface-Mount Devices

Many different electronic parts come in SMD form. You might not see them, but they are inside almost every electronic device you use.

- Resistors: These control the flow of electricity. SMD resistors look like tiny black or brown rectangles.

- Capacitors: These store and release electrical energy. SMD capacitors are also small rectangles, often unmarked.

- LEDs: Light-emitting diodes are tiny lights. SMD LEDs are used in screens and indicator lights.

- Integrated Circuits (ICs): These are like the "brains" of electronics. They can contain millions of tiny parts. SMD ICs are flat, black chips with many small metal legs.

How SMDs Are Put Together

Making circuit boards with SMT involves special machines.

Pick-and-Place Machines

After a special paste (like glue with tiny bits of solder) is put on the board, a "pick-and-place" machine takes each tiny SMD. It uses a vacuum to pick up the part and then places it exactly where it needs to go on the circuit board. These machines are very fast and precise.

Soldering Process

Once all the parts are placed, the circuit board goes into a special oven. This oven heats the board just enough to melt the solder paste. When the solder cools down, it hardens and creates strong electrical connections between the SMDs and the board. This process is called "reflow soldering."

SMT vs. Through-Hole Technology

Before SMT, most electronic parts were "through-hole."

- Through-Hole Parts: These have long metal wires (leads) that go through holes drilled in the circuit board. The wires are then soldered on the other side. This method is still used for some larger or stronger parts.

- SMT Parts: These have small metal pads or short leads that sit directly on the surface of the board. They are much smaller and allow for more compact designs.

SMT has largely replaced through-hole technology for most modern electronics because of its many benefits.

Images for kids

-

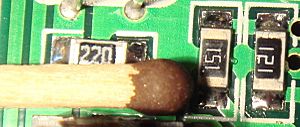

Surface-mount components on a USB flash drive's circuit board. The small rectangular chips with numbers are resistors, while the unmarked small rectangular chips are capacitors.

-

A MOSFET transistor, placed upon a British postage stamp for size comparison.

-

Removing a surface-mount device using soldering tweezers.

See also

In Spanish: Tecnolog%C3%ADa de montaje superficial para ni%C3%B1os

In Spanish: Tecnolog%C3%ADa de montaje superficial para ni%C3%B1os

| Aurelia Browder |

| Nannie Helen Burroughs |

| Michelle Alexander |