Tunnelling shield facts for kids

A tunnelling shield is a special protective structure used when people dig large tunnels. Imagine you're digging a hole in soft sand – it might collapse! Tunnelling shields work like a strong, temporary wall to keep workers safe from falling dirt or cave-ins.

These shields stay in place only for a short time. They protect the digging area until a permanent tunnel wall can be built right behind them. This permanent wall can be made of bricks, concrete, or metal. The very first shield, designed by Marc Isambard Brunel, was a big, rectangular iron frame. Today, most shields are shaped like a cylinder, like a giant pipe.

Contents

How Tunnelling Shields Began

The first successful rectangular tunnelling shield was invented by Marc Isambard Brunel and Thomas Cochrane, 10th Earl of Dundonald in 1818. Brunel and his son, Isambard Kingdom Brunel, used it to dig the famous Thames Tunnel in London, starting in 1825. This tunnel finally opened in 1843.

Brunel got his idea from a tiny creature called a shipworm. He noticed how this mollusc could bore through wood underwater without the tunnel collapsing. The company Maudslay, Sons & Field built Brunel's shield and the powerful steam pumps that kept the tunnel dry.

In 1840, Alfred Ely Beach, who edited Scientific American magazine, thought a round shield would be better than Brunel's rectangular one. In 1868, Beach built a circular shield for his own tunnel project.

Later, James Henry Greathead made big improvements to Brunel's design. He got several patents for new shield designs. He also invented a way to spray concrete grout (a type of liquid concrete) to make the ground stronger. He also created a system to inject grout into the gaps between the tunnel lining and the surrounding earth.

Greathead was the first to use a cylindrical tunnelling shield. He used it to build the Tower Subway under the River Thames in London in 1869. This shield was about 7 feet 3 inches (2.2 meters) wide.

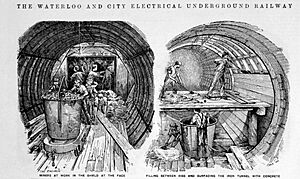

Greathead's shields were also used for the City and South London Railway (now part of the London Underground's Northern line) in 1884. Those tunnels were about 10 feet 2 inches (3.1 meters) wide. His shield also helped build the Waterloo & City Railway tunnels, which were 12 feet 1¾ inches (3.7 meters) wide and opened in 1898. The station tunnels at Bank (then called City station) were huge for their time, measuring 23 feet (7 meters) across!

You can still see an original Greathead shield today! It's in some old tunnels under Moorgate station in London. Most modern tunnelling shields are still based on Greathead's clever ideas.

How Early Shields Worked

In the early days of tunnelling, the shield was a safe space for workers. They would dig the dirt out in front of the shield, and then the shield would be pushed forward. As the shield moved, workers would build new sections of the tunnel wall behind it. This is how many of the first deep tunnels for the London Underground were made. The shield had different sections, so each worker had a specific area to dig.

Modern Tunnel Boring Machines

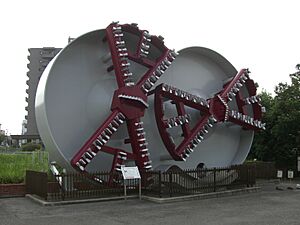

Today, we use huge machines called Tunnel Boring Machines (TBMs). A TBM is basically a very advanced tunnelling shield with lots of extra parts.

At the very front of the TBM is a big, rotating cutting wheel. This wheel grinds away the soil or rock. Behind the cutting wheel, there's a special chamber. Here, the dug-out soil is either mixed with a special liquid called slurry or kept as it is. The type of TBM used depends on the kind of ground being dug through. There are also systems to remove all the dug-out material.

Behind this chamber are powerful hydraulic jacks. These jacks push the TBM forward by pushing against the part of the tunnel that has already been built. Once the TBM has moved forward a certain distance (about 5 to 6.5 feet or 1.5 to 2 meters), a new ring of the tunnel wall is built. A rotating system called an "erector" picks up pre-made concrete pieces and puts them into place to form the new tunnel ring.

Inside the finished part of the tunnel, behind the shield, are many support systems. These include equipment for removing dirt, pipes for slurry (if used), control rooms for the operators, and rails to bring in the pre-made concrete pieces.

Tunnel Walls: The Lining

The tunnel lining is the actual wall of the tunnel. It's usually made of pre-made concrete pieces that fit together to form rings. In the past, London Underground tunnels often used cast iron linings, while other places sometimes used steel. The idea of using pre-made sections for the tunnel wall isn't new; James Henry Greathead actually patented it in 1874!

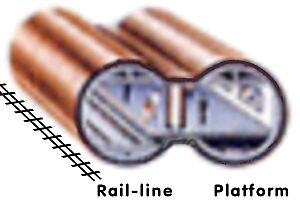

Cool Shields in Japan

Japan has some really cool and new ways of using shield tunnelling. One example is the Double-O-Tube, or DOT-tunnel. This tunnel looks like two circles that overlap! There are also shields with computer-controlled arms that can dig tunnels in almost any shape you can imagine.

See also

- Longwall mining, a method used to mine coal that also uses special protective shields.

| Dorothy Vaughan |

| Charles Henry Turner |

| Hildrus Poindexter |

| Henry Cecil McBay |