West End Gasworks facts for kids

Quick facts for kids West End Gasworks |

|

|---|---|

West End Gasworks Distribution Centre, 1999

|

|

| Location | 321 Montague Road, West End, Queensland, Australia |

| Official name: West End Gasworks Distribution Centre, South Brisbane Gas and Light Company Works, West End Gasworks | |

| Type | state heritage |

| Designated | 22 October 1999 |

| Reference no. | 601595 |

| Lua error in Module:Location_map at line 420: attempt to index field 'wikibase' (a nil value). | |

The West End Gasworks is a historic site in West End, Australia. It used to be a place where gas was made and stored. This site, also known as the South Brisbane Gas and Light Company Works, was added to the Queensland Heritage Register on October 22, 1999. It played a big part in bringing gas to homes and streets in South Brisbane.

The Story of West End Gasworks

The West End Gasworks started in June 1885. It was built to help supply gas to the growing city of Brisbane. Gas had already been used in London since 1812, Sydney since 1841, and Melbourne since 1856. Brisbane got its first gas supply in 1865 at Petrie Bight.

Gas Comes to Brisbane

In the 1860s, Brisbane's population grew very fast. The city needed better services, like street lighting. Gas was the best way to light streets back then. The Brisbane Gas Company started supplying gas, mostly to the north side of the Brisbane River.

By 1885, a new company, The South Brisbane Gas and Light Company Limited, was formed. It aimed to supply gas to the south side of the river. This area was developing quickly with many new homes. These homes needed gas for lighting, cooking, and heating.

The original gasworks was designed by John Davies. He was the company's first engineer. Construction finished, and gas was first supplied on December 22, 1886.

Competing for Customers

At first, the two gas companies in Brisbane competed fiercely. They even had a price war! But by 1889, they decided to split Brisbane into two areas. The Brisbane Gas Company served the north, and the South Brisbane Gas and Light Company served the south.

Later, in 1916, the government passed the Gas Act. This law looked at how gas companies operated. It made sure gas quality and pressure were good. It also helped control gas prices.

Dealing with Floods

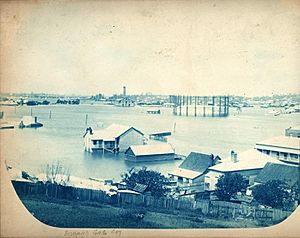

The gasworks was built near the Brisbane River. This meant it was at risk of flooding. In 1890, a flood hit the gasworks but did not cause too much damage. However, the 1893 floods were much worse. They caused serious damage and even destroyed one of the large gas holders. Many important documents and drawings were also lost.

After the 1893 flood, some people thought the city should use electricity for street lights instead of gas. The flood also destroyed many homes in the area. This reduced the number of customers for the gas company.

Improving the Gasworks

Over the years, the gasworks was updated many times. In 1914, Engineer William Summers Moore oversaw a big upgrade. This made the process of making gas much more efficient. It meant they could get more gas from each ton of coal.

In 1930, another major upgrade happened. This time, WH Shedden, the new Engineer and Manager, designed the changes. They added new equipment, like a "Glover-West vertical retort house." This further improved how efficiently gas was made.

The company also started using "high-pressure reticulation" for new areas. This meant gas could be sent further and more easily. One of the old electric compressors from this time, called No. 2, is still there today.

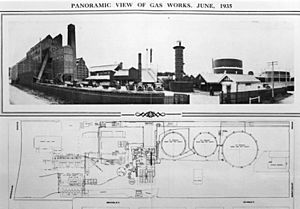

By 1935, the site had three large gas holders. These were huge tanks that stored the gas. They could hold a total of 922,000 cubic feet of gas! Over time, these were replaced or updated.

Moving to Natural Gas

In the late 1960s, natural gas became available. It was a cleaner and more efficient fuel. The South Brisbane Gas Company decided to switch to natural gas. In December 1969, the old plant that made gas from coal was shut down. The retort house, where gas was made, was demolished in 1974.

The company's name also changed to Allgas Energy Ltd in 1971.

The 1974 flood caused more damage to the site and its records. Most of the old manufacturing and purification equipment was demolished in 1974 and 1975. Today, there are no signs of how gas was made from coal on the site.

Some parts of the old site were sold off. The remaining part became a place to distribute natural gas. The three large gas holders were kept for a while. By 1994, the site was known as the West End Distribution Centre. Only one gas holder, No. 1, was still in use for emergencies. The Ekibin gas holder was taken down in 1999.

In 2003, the Queensland Heritage Council allowed the remaining parts of the gasworks to be demolished. But they made sure that the site was recorded with photos first. Some important parts, like the gate and a special device called a governor, were saved.

What Remains Today

Most of the original gas-making equipment has been removed. This includes things like the retort houses and purifiers. These were on the western side of the site, which has now been redeveloped.

However, in September 1999, some interesting historical items were still there. Many of these were later removed or saved for new developments. Here are some of the things that were present:

- No. 1 Gasholder: This was a very large, four-part gas holder. It was built around the 1940s. It sat in a brick tank about 38 meters wide and 6 meters deep. It could hold 908,000 cubic feet of gas.

- Gasholder Tanks: There were also two other brick tanks. One, No. 2, was about 24 meters wide and contained water. The other, No. 3, was also 24 meters wide but was filled with earth.

- Weighbridge: A dismantled weighbridge was found near the Beesley Street fence. This was used to weigh incoming coal and outgoing coke.

- Governor: A special device called a governor was in a small brick building. It was made by W Parkinson of London and likely dates back to the 1880s.

- Laboratory: A laboratory with its equipment was in a brick building on the northern side.

- Compressor House: This was a brick building that held large machines called compressors. These machines helped push the gas through pipes.

- Inside were three main compressors. No. 1 was made in 1949. Nos. 2a and 2b were older. No. 3 was made in 1950. These compressors were powered by electric motors.

- Engine Drivers Room: This brick building was once a meter room. It also housed a standby generator. This generator could provide power if the main electricity went out.

- Receiver Vessel: A large metal tank on concrete supports was near the north fence. This tank stored compressed gas from around 1930. It helped supply gas to the medium-pressure pipes.

- Art Deco Fence: A decorative fence with gates runs along Montague Road. It has a cool Art Deco style.

Why This Place is Special

The West End Gasworks Distribution Centre is important for several reasons. It helps us understand the history of gas supply in Brisbane.

A Look at History

The site shows how a vital public service, gas supply, grew and changed. It reflects the development of South Brisbane from the 1880s to the 1990s. It tells us about the economic and social growth of the area.

Unique and Rare Features

The remaining gasholder was the last of its kind in Brisbane. It was a "spiral guide type" gasholder. While many gasholders have been removed, this one was a rare example. The station governor, a device that controlled gas pressure, was also unique in Brisbane.

Showing How Gasworks Worked

The remaining parts of the site, like the gasholder tanks, compressors, and the receiver vessel, show how a gasworks operated. They demonstrate the strong and reliable machinery needed to store and deliver gas. The brick tanks also show how bricks were used in big industrial buildings. The compressors show the change from steam power to electric power for pumping gas.

Beautiful and Interesting Design

Large round structures like the gasholder are unusual and look interesting. Especially in areas with many square industrial buildings. The gasholder, even when empty, was seen as elegant. The round brick tanks also add to the site's unique look. The two main brick buildings, the compressor house and the engine drivers room, are also attractive old industrial buildings.

Smart Engineering

In 1930, the engineer JH Shedden suggested using high-pressure gas distribution. This was a very smart idea for its time. It allowed the gasworks to supply gas to a much wider area. The receiver vessel on the site is a reminder of this important technical achievement.

| William L. Dawson |

| W. E. B. Du Bois |

| Harry Belafonte |