3D food printing facts for kids

3D food printing is a cool way to make food using a special machine called a 3D printer. Think of it like a regular printer that uses ink, but instead, a 3D food printer uses edible materials! These materials come out of tiny nozzles, building up your food layer by layer.

One great thing about 3D food printing is that you can create unique dishes in any shape you want. You can also make food that fits special dietary needs, like if someone has allergies or needs certain nutrients.

Contents

How It Started

The idea of 3D printing was invented by Chuck Hull in the USA in 1986. But it wasn't until the 2000s that this technology started being used for food.

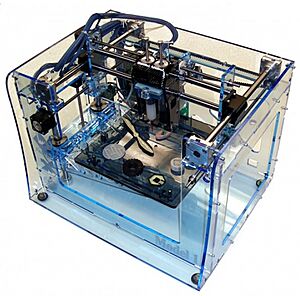

The first tests of 3D food printing happened in 2007 at Cornell University and Massachusetts Institute of Technology (MIT). A team at Cornell University had already created the Fab@Home 3D printer in 2006. This printer could make foods like chocolate, cookie dough, and cheese!

How 3D Food Printing Works

For food to be printed perfectly, three main things are important:

- The ingredients or materials the printer uses.

- How the food comes out of the printer and how fast it does.

- What happens to the food after it's printed (like if it's baked, microwaved, or eaten as is).

The Printing Steps

First, you fill a special container in the 3D printer with the food material. This container looks a bit like a syringe. The printer then warms up the material and pushes it out through a special nozzle, building the food layer by layer. If you use dry powder ingredients, the printer sprays them with an edible liquid to make them solid before printing.

You can program the printer with recipes that are already saved. Or, you can design your own food using computers, phones, or even smart devices connected to the internet.

What Materials Are Used?

The edible materials, or "ink," used in these printers can be many different things:

- chocolate

- purée (like fruit or vegetable puree)

- jelly

- frosting

- cheese

- mashed potatoes

- dough (like cookie dough)

- Powdered ingredients

Special Additives

Sometimes, special ingredients called transglutaminase and hydrocolloids are added to the food materials. These help the food keep its shape after it's printed.

Cool Uses for 3D Food Printing

3D food printing has many exciting uses:

- Personalized Meals: Imagine food made just for you! People with food allergies or older adults can get meals made to fit their exact needs. For example, in 2019, a company called Nourished started 3D printing personalized nutritional gummies. You can take a survey and get a gummy made with the specific vitamins you need.

- Amazing Food Designs: 3D food printing lets you create super detailed and fancy designs with food, especially with sugar. Sometimes, kids will even eat healthy meals if they are printed in a fun, cool shape!

- Less Food Waste: A lot of food gets wasted when it's processed, shipped, or even eaten. 3D printing can help reduce this waste. Food that might not look perfect can be used as the "ink" to make new, better-looking food. A Dutch company, Upprinting Food, blends leftover ingredients to create purees for 3D printing. Chefs are also using 3D printers to make new dishes from food that would otherwise be thrown away.

- Food for Space: For astronauts on long space missions, it's hard to store food. 3D food printing can create food that is both nutritious and easy to keep in space.

- Helpful in Medicine: This technology can also help people with health issues. For example, it can make food that is easier to swallow for people who have trouble eating (a condition called dysphagia). It can also create food that is easier to digest for those with stomach or gut problems.

What Are the Challenges?

Even though 3D food printing is amazing, there are some challenges:

- Higher Cost: Right now, 3D food printing is more expensive than making food the traditional way. The printers themselves are costly, and they need special food-grade materials.

- No Clear Rules: There aren't many specific rules or laws for 3D food printing yet. This can make some people feel a bit unsure about it.

- Limited Designs: While it can make cool shapes, the design options for 3D printed food are still limited compared to what chefs can do by hand.

- Ingredient Problems: Not all ingredients can be used in a 3D printer. Some just don't work well.

- Shorter Shelf Life: 3D printed food often doesn't last as long as regular food products unless it's stored and packaged very carefully.

- Hard to Get Ingredients: It can be tricky to find and get the right ingredients that work best for 3D food printing.

- It's Slow: One of the biggest challenges is speed. 3D food printing is currently much slower than traditional ways of making food.

Fun Facts About 3D Food Printing

- Making just one 3D-printed food item can take anywhere from 7 to 45 minutes!

- The famous chocolate company Cadbury uses custom 3D printers to create molds and test out new sweets.

- Barilla, a well-known Italian pasta company, is working on a pasta 3D printer. It can make tiny works of art from durum wheat flour.

- Most food 3D printing needs the ingredients to be melted or mashed into a paste so the machine can push them out.

- A Chinese company called Beets once made jelly animals and figures using Philadelphia cream cheese!

See also

- 3D Printing

- Multi-material 3D printing

- 3D bioprinting

- 3D Scanning

- 3D Modelling

- Fused Deposition Modeling (FDM)

- Selective Laser Sintering

- Inkjet Printing

- IoT

- Fab@Home

- Transglutaminase

- Hydrocolloids

- Viscosity

- Edible ink printing