Inkjet printing facts for kids

Inkjet printing is a type of computer printing that makes a digital image by spraying tiny drops of ink onto paper or plastic. For a long time, inkjet printers were the most common type of printer for homes. They ranged from small, affordable models to large, expensive machines used by professionals.

The idea for inkjet printing started in the 1900s. The technology really began to grow in the early 1950s. In the late 1970s, companies like Epson, Hewlett-Packard (HP), and Canon developed inkjet printers that could print digital images from computers. Today, Canon, HP, Epson, and Brother sell most of the inkjet printers around the world.

In 1982, Robert Howard thought of a way to make a small color printer. It used special crystals called piezos to shoot out ink drops. His company, Howtek, Inc., created the Pixelmaster color printer. This printer used "solid ink" (like wax) and a technology called Thermojet. This showed that inkjet technology could do more than just print on paper.

Today, inkjet technology is also used to place materials directly onto surfaces. For example, it can put solder paste on printed circuit boards (PCBs). It can even place living cells for creating biosensors and for tissue engineering.

Sometimes, high-quality art prints made with inkjet printers are sold under special names like giclée. This makes them sound more artistic and different from everyday printing.

Contents

How Inkjet Printers Work

Inkjet printers work by creating tiny drops of ink. These drops are very small, about 0.004 inches wide. The nozzles that spray the ink are even smaller, about 0.003 inches. The ink can be water-based, wax-based, oil-based, or even melted metal.

There are two main ways inkjet printers make these drops:

- Continuous Inkjet (CIJ): This method sprays a constant stream of ink.

- Drop-on-Demand (DOD): This method sprays ink one drop at a time, only when needed.

Continuous Inkjet Printing

The continuous inkjet (CIJ) method is often used in factories. It marks and codes products and packages. The first commercial CIJ devices were used in 1951.

Here's how it works:

- A pump pushes liquid ink from a tank through a tiny nozzle. This creates a steady stream of ink.

- A special crystal vibrates. This causes the ink stream to break into many small droplets. This can happen very quickly.

- As the drops form, they pass through an electric field. This field gives each drop a controlled electric charge.

- The charged drops then pass through another electric field. This field steers the drops.

- Drops that are charged are directed to print on the paper or product. Uncharged drops are not used. They go into a collection area to be reused. Only a small number of drops are actually used for printing.

CIJ is an older but very reliable technology. Its main benefits are:

- High speed: The ink drops move very fast, allowing for quick printing.

- Long distance: The print head can be quite far from the surface being printed on.

- No clogging: Since the ink is always flowing, the nozzles are less likely to get blocked. This also means the ink can dry quickly.

In the 1950s, heated wax inks became popular with CIJ printers. Later, in 1971, someone even patented using melted metal as ink to print 3D objects!

Drop-on-Demand Printing

Drop-on-demand (DOD) inkjet printers only release ink drops when they are needed. This can be done in many ways. The most common are thermal DOD and piezoelectric DOD. DOD printers can have just one nozzle or thousands. Modern DOD printers can control how many drops of ink are placed at each spot.

DOD technology is very popular today. It can use many types of "ink." This includes thick pastes, glues, hot-melt inks, and even biological fluids.

Thermal Drop-on-Demand Printing

Most home inkjet printers, including those from Canon and Hewlett-Packard, use the thermal inkjet process. The idea came from two groups working separately in the late 1970s. One engineer at Canon accidentally discovered that ink shot out of a syringe when it was heated.

Here's how thermal inkjet works:

- The print cartridges have many tiny chambers. Each chamber has a small heater.

- When a quick electric pulse goes through the heater, the ink in the chamber heats up very fast. It turns into a bubble of vapor.

- This bubble creates a lot of pressure. This pushes a tiny drop of ink onto the paper. This is why Canon calls its system "Bubble Jet."

- When the bubble cools and shrinks, more ink is pulled into the chamber from the ink tank. It is then ready for the next drop.

- Thermal inks are usually water-based. They use either pigments or dyes for color. They must have a part that can turn into vapor to make the bubble.

- These print heads are usually cheaper to make because they don't need special materials.

Piezoelectric Drop-on-Demand Printing

Many professional and some home inkjet printers (like those from Epson and Brother Industries) use a piezoelectric material. This material is in an ink-filled chamber behind each nozzle.

Here's how piezoelectric inkjet works:

- When electricity is applied, the piezoelectric material changes shape.

- This change in shape creates a pressure pulse in the ink.

- This pressure pushes a drop of ink out of the nozzle.

- Piezoelectric inkjet can use a wider range of inks than thermal inkjet. This is because it doesn't need the ink to vaporize.

- However, these print heads are more expensive to make. This is due to the special piezoelectric material used. But, the ink cartridges can be separate from the print head. This can make them cheaper to run over time.

Printing with Solid Inks (3D Printing)

In the 1970s, most DOD inks were water-based. But in the late 1970s and 1980s, companies started using wax- and oil-based inks. In 1984, a company called Howtek found that solid ink materials (like plastics that melt when heated) could be sprayed at high temperatures.

Howtek launched the Pixelmaster printer in 1986. It used solid ink. This opened the door to printing three-dimensional plastic objects. This technology led to patents used by the first major 3D printer companies.

Howtek also created the Braillemaster in the late 1980s. This printer used four layers of solid ink. It created Braille documents that blind people could read.

Today, some companies still use Howtek-style solid ink materials and nozzles for 3D printing. These printers can make many drops per second. They can print 3D models with hundreds of layers.

What's in Inkjet Inks?

The biggest challenge with inkjet inks is this: the coloring part needs to stay on the surface. But the liquid part needs to dry quickly without spreading too much.

Water-Based Inks

Most home and office inkjet printers use aqueous ink. This ink is made mostly of water, glycol, and dyes or pigments.

- These inks are cheap to make.

- They can be hard to control on regular paper. They often need special coated paper.

- They are mainly used in printers with thermal inkjet heads. These heads need water to make the ink drops.

- Water-based inks usually give the brightest colors.

- However, most are not waterproof unless the print is specially coated.

- Dye-based inks are usually the cheapest. But they can fade quickly in light.

- Pigment-based inks cost more. But they last much longer and resist ultraviolet light better. Inks called "archival quality" are usually pigment-based.

Solvent Inks

These inks mainly contain volatile organic compounds (VOCs). They use pigments for color. This makes them very resistant to fading.

- Solvent inks are relatively inexpensive.

- They can print on flexible, uncoated vinyl materials. These are used for things like car graphics, billboards, and banners.

- A downside is that they produce vapors. They need proper ventilation.

- Unlike most water-based inks, solvent-based prints are usually waterproof and UV-resistant for outdoor use.

- They dry quickly. They often need heaters and fans in the printer.

- "Mild" or "eco-solvent" inks are safer for indoor use without special ventilation.

UV-Curable Inks

These inks are made of monomers and a special starter. After printing, the ink is hardened by strong UV light.

- The UV light causes a chemical reaction. This turns the liquid ink into a solid.

- This reaction happens very fast, so the ink dries instantly.

- UV inks don't evaporate. So almost all the ink volume is used for color.

- They can be used on many different uncoated materials.

- They create a very strong and durable image.

- Disadvantages include being expensive. They also need special UV lights in the printer.

- They are often used in large "flatbed" printers. These print directly onto hard materials like plastic, wood, or aluminum.

Dye Sublimation Inks

These inks contain special sublimation dyes. They are used to print on fabrics. Especially those with a lot of polyester.

- When heated, the dyes turn into a gas. They go into the fabric fibers.

- This creates a strong, colorful, and durable image.

Solid Ink

These inks are mostly made of waxy compounds. They are heated until they melt for printing. Then they harden when they hit the cool surface.

- Solid inks are often used for special printing. This includes creating masks or for graphic printing.

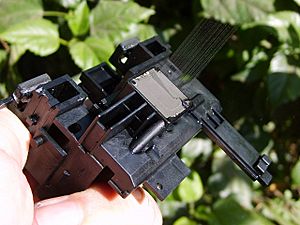

Print Heads: Fixed or Disposable?

Inkjet printers use different types of print heads: fixed-head or disposable head. Each has its own good and bad points.

Fixed Print Heads

A fixed print head is built into the printer. It is meant to last for the printer's entire life.

- Pros: Since you don't replace the head often, ink costs can be lower. The head can also be made more precisely.

- Cons: If a fixed head gets damaged or clogged badly, it can be very expensive to replace. You might even need to buy a whole new printer.

Fixed heads are common in industrial and large-format printers. Epson and Canon use them in some of their home printers. Many newer HP models do too.

Disposable Print Heads

A disposable print head comes as part of a replaceable ink cartridge.

- Pros: If the print head gets damaged or clogged, it's an easy fix. Just buy a new cartridge.

- Cons: This makes the ink cartridges more expensive. This is because you're buying a new print head every time. It also makes it harder to make a very precise head cheaply.

Hewlett-Packard has often used disposable print heads. Some printers use a mix: a disposable ink tank connected to a head that is replaced less often.

For 3D printers, print heads can wear out over time. So, replacement print heads are usually available as spare parts for these long-use printers.

How Printers Clean Themselves

The biggest problem with inkjet printers is that ink can dry on the tiny nozzles of the print head. This can block the ink from coming out. Most printers try to stop this by covering the nozzles with a rubber cap when not in use. But even with the cap, ink can still dry out over time.

To fix this, almost all inkjet printers have a cleaning system:

- The printer tries to spray ink from all nozzles at once. Some of this ink helps soften any dried ink.

- Then, a rubber blade wipes across the print head. This spreads moisture evenly.

- Finally, the jets spray again to push out any remaining ink clumps.

Some printers also have a pump that sucks ink through clogged cartridges. This pump is also used to get ink flowing when a new printer is first set up or when ink tanks are changed.

The ink used for cleaning needs to go somewhere. It's collected in a special area called a spittoon. In some printers, this is an open tray. In others, it's an absorption pad. If a printer is old, this dried ink can build up and cause problems.

Another drying problem happens inside the ink cartridge. Air needs to enter the cartridge as ink is used. This air can cause the ink to dry from the inside. To prevent this, many professional printer cartridges use an airtight, collapsible bag for the ink. The bag just shrinks as ink is used, so no air gets in.

All this cleaning uses up a lot of ink. This can make printing more expensive. If nozzles are clogged, you can print a test pattern to check. Some software can even send printing information from a clogged nozzle to a working one.

Ink Delivery Systems

Ink cartridges have been the usual way to deliver ink to the print head. Newer systems include:

- Continuous ink system (CISS): These printers connect the print head to large ink tanks. Or they refill the built-in cartridges using external tanks connected by tubes.

- Supertank printers: These are a type of CISS printer. They have large, built-in ink tanks or packs. You refill them manually with ink bottles.

Good Things About Inkjet Printers

Compared to older printers, inkjet printers have many good points:

- They are much quieter than impact dot matrix or daisywheel printer printers.

- They can print finer, smoother details because they have higher resolution.

- You can easily buy home inkjet printers that print photos with great quality.

- They usually don't need to warm up, unlike laser printers.

- The cost per page can be lower than some other printing methods. However, low-cost laser printers can sometimes have lower costs, especially for black and white.

Some types of industrial inkjet printers can now print very fast. They can print in wide formats. They can also be used for many industrial jobs. This includes signs, textiles, and even 3-D printing.

Not-So-Good Things About Inkjet Printers

Ink Cartridge Challenges

Many "smart" ink cartridges have a tiny microchip. This chip tells the printer how much ink is left. Sometimes, the printer might say the cartridge is empty even when there's still a good amount of ink inside. Some inkjet printers will even refuse to print if the chip says a cartridge is empty. This can happen even if you only need black ink and a color cartridge is low.

This has led to many companies selling cheaper, third-party ink cartridges or refill kits. Printer makers often warn against using these. They say they can damage the print heads or give bad print quality. However, some studies have shown that third-party inks can work well.

Clogging and Maintenance

The very small nozzles on inkjet print heads can easily get clogged. The ink used for cleaning (either by you or automatically by the printer) can be a lot. This adds to the cost of printing.

If a print head gets clogged, you can sometimes clean it with special liquids or warm water. But if a fixed print head gets permanently clogged, you might have to throw away the whole printer. Printers with disposable print heads are easier to fix. But their ink cartridges are usually more expensive per page.

Laser printers don't have print heads that clog. They usually need less maintenance.

Print Durability

How long an inkjet print lasts depends a lot on the quality of the inks and paper.

- If cheap paper is used, it can turn yellow and fall apart over time.

- Many low-cost inkjet inks are water-soluble. This means even a small drop of water can cause them to blur or run. Sweaty fingers can also cause smudges.

- Dye-based inks can fade over time, especially in light.

- Pigment-based inks are much more durable and water-resistant. Many newer printers use pigment-based inks, at least for black.

- Special photo papers can also make prints more resistant to water and smudges.

High-quality inkjet art prints are sometimes called "giclée" prints. But this term doesn't guarantee quality. It's important to check the inks and paper used.

To make your inkjet prints last longer, try to keep your printer in a room with a steady temperature. Big changes in temperature can make ink cartridges dry out faster.

How Printer Companies Make Money

A common way for inkjet printer companies to make money is by selling the printer itself cheaply. Sometimes even below cost. But they sell the ink cartridges at a much higher price. This is like selling a razor cheaply but making a lot of money on the blades.

To make sure people buy their expensive ink, many printer companies use different methods:

- They put microchips in the cartridges. These chips track ink use. They can make the printer stop working when it thinks the cartridge is empty. This happens even if the cartridge is refilled.

- Some manufacturers also put "expiration dates" on cartridges.

Many people are unhappy about the high cost of ink. This has led to many companies selling cheaper, third-party ink cartridges or refill kits. Printer makers often warn against using these. They say they can damage the printer or give bad print quality. However, many users still choose these cheaper options.

In recent years, some printer companies have started a new business model with "supertank printers."

- These printers have large, built-in ink tanks. You refill them from inexpensive ink bottles.

- The printer itself costs more upfront. But the ink bottles are very cheap and last for thousands of pages.

- Epson started this with their EcoTank range. Canon and HP now have their own versions called MegaTank and Smart Tank.

Region-Coding for Printers

Some manufacturers put "region codes" on their printers and cartridges. This is similar to DVD movies. It means you might not be able to use a printer or ink from a cheaper region in another. You can sometimes change the region code a few times. But then the printer gets locked to that region.

One way around this is to refill empty cartridges from your old region with ink from the new region. Another way is to have ink cartridges shipped from your old region. Some companies also offer special "region-free" printers for people who travel a lot.

Types of Inkjet Printers

Professional Inkjet Printers

Besides the small inkjet printers for homes, there are also professional inkjet printers.

- Page-width printers print on paper from about 8.5 to 37 inches wide. They are used for printing many business documents like bills or personalized newspapers.

- Wide format printers print on materials from 24 inches up to 15 feet wide. These are often used for advertising graphics like billboards, banners, and building wraps. They are also used for printing design documents for architects.

Some inkjet printers are used to make color proofs for big printing jobs. These printers are designed to show exactly how the final printed image will look.

Big companies like HP, Epson, and Canon make wide-format printers. Other companies like Mimaki, Roland, and Mutoh also make them, often using Epson print heads.

Home Photo Printers

SOHO (Small Office/Home Office) multifunction inkjet printers for photo printing use up to 6 different inks:

- Canon: cyan, yellow, magenta, black, pigment black, gray.

- Epson: cyan, yellow, magenta, light cyan, light magenta, black.

Professional Inkjet Photo Printers

Inkjet printers for professional photo printing use up to twelve different inks. This allows them to print very detailed and colorful images on large photo paper.

Compact Photo Printers

A compact photo printer is a small, stand-alone inkjet printer. It is designed to print 4x6 or 2x3 inch photos directly from digital cameras. It works without needing a computer.

- These printers are small, often with screens. This lets you browse and edit photos.

- They usually have many ways to connect, like USB and different memory card slots.

- Most major printer companies make compact photo printers.

Other Cool Uses for Inkjet Printers

Inkjet printers can do more than just print on paper!

- You can print edible photos onto birthday cakes. This uses food-grade inks and special printers. Many bakeries do this now.

- Inkjet technology is used to make tiny items in micro-electromechanical systems.

- They are used to create conductive paths for electronic circuits. They also make color filters for LCD and plasma screens.

- Inkjet printers are used in labs. They help develop ways to use expensive or rare materials. This includes printing polymers, nanoparticles, and carbon nanotubes.

- Inkjet technology is also used in the emerging field of bioprinting (printing living cells). They are also used for making OLED displays.

See also

In Spanish: Inyección de tinta para niños

In Spanish: Inyección de tinta para niños

- Supertank printer

- Edgeline printing

- Inkjet solar cell

- Inkjet technology

- Inkjet transfer

- Intelligent Interweaving technology

- ISO Standards for colour ink jet printers

- Laser printing

- Memjet

- Microfluidics

- Society for Imaging Science and Technology

- Tonejet

- UV pinning

- Water-jet printer

| Chris Smalls |

| Fred Hampton |

| Ralph Abernathy |