Boston Manufacturing Company facts for kids

|

Boston Manufacturing Company

|

|

Boston Manufacturing Company, Waltham, Massachusetts

|

|

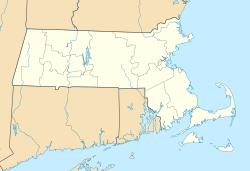

| Location | 144-190 Moody St., Waltham, Massachusetts |

|---|---|

| Built | 1813 |

| Architect | Paul Moody |

| NRHP reference No. | 77001412 |

Quick facts for kids Significant dates |

|

| Added to NRHP | December 22, 1977 |

| Designated NHLD | December 22, 1977 |

The Boston Manufacturing Company was a very important business in early American history. It started one of the first successful factories in the United States. In 1813, a rich merchant named Francis Cabot Lowell teamed up with other investors. They wanted to make cotton cloth.

They built the world's first factory that could spin cotton into yarn and weave it into cloth all in one place. This factory was in Waltham, Massachusetts. It used water power from a river to run its machines. Lowell had secretly brought plans for a special machine called a power loom from England. This factory became the largest in the U.S. at the time, with about 300 workers. It was very efficient and made a lot of money. The company's ideas were later copied in other towns like Lowell, Massachusetts.

How the Factory Started

Before this factory, making cloth was a slow process. Since 1793, machines powered by water had been spinning cotton into yarn. But this yarn then had to be sent to small shops or homes. There, people used hand-operated looms to weave it into cloth. By 1810, many spinning mills existed in New England, but making cloth was still quite slow.

In 1810, Francis Cabot Lowell visited England. He studied their successful textile factories. He was especially interested in the power loom. This machine could weave cloth much faster than by hand. Lowell knew America needed such a machine to make more cloth. When he returned to Boston in 1812, he had memorized the plans for the power loom. He had to be careful because England did not allow this new technology to leave the country.

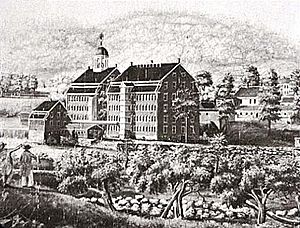

In September 1813, Lowell and his partners bought a paper mill site in Waltham. The nearby Charles River had a ten-foot drop in its water level. This made it a perfect spot to build their new water-powered factory.

A Manufacturing Revolution

The group hired a skilled mechanic named Paul Moody. He was from Amesbury. Moody's job was to design and build the factory's machinery. He also oversaw the construction of the new mill.

After more than a year of testing, Moody successfully built Lowell's power loom. He even made his own improvements to it. Moody's perfected power loom changed American industry forever. For the first time, all the steps of making cloth could happen in one building. Moody also created a new way to transfer power using leather belts and pulleys. This system, powered by water turbines, was much more efficient than older methods. The first mill was finished in late 1814.

By early 1815, the factory was selling its cloth. Production and profits grew quickly. In 1816, a second, larger mill was built next to the first. This new mill not only made cloth but also built textile machines for other companies. The two mills were later connected in 1843 as the company expanded. Many other mills in New England soon copied the power loom. Francis Cabot Lowell passed away in 1817 at the age of 42.

The Waltham System of Work

The Boston Manufacturing Company wanted to create a good system for its workers. They wanted to avoid the harsh conditions seen in English factories. So, they hired young women from nearby farms. These "mill girls" came to work the machines in Waltham. The company provided boarding houses for them. Older women supervised the girls, and they had to follow strict rules.

The mill girls worked about eighty hours each week. Their day started early, with a factory bell ringing at 4:40 in the morning. They began work at 5:00 a.m. and had a half-hour breakfast break at 7:00 a.m. They worked until noon, when they had a lunch break of about 30 to 45 minutes. The factory closed at 7:00 p.m., and the workers returned to their company homes. This routine was followed six days a week. This way of organizing work and life became known as the Waltham System.

By the early 1820s, the Waltham factory was using almost all the available water power from the Charles River. The investors looked for a new place to build even more mills. In 1822, they started the Merrimack Manufacturing Company. They copied the Waltham System on a much larger scale in the new city of Lowell, Massachusetts. The same group of investors later helped create other industrial cities. These included Lawrence, Massachusetts and Manchester, New Hampshire. The factory methods started in Waltham were also copied by other industries in the years that followed.

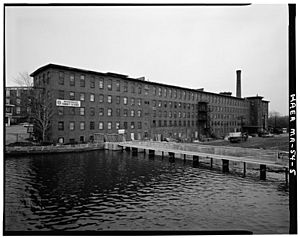

The Waltham site was expanded again in the late 1800s. The original mills were connected, and new floors were added. The Boston Manufacturing Company finally closed in 1930.

In 1977, the site was recognized as a National Historic Landmark. Some of the company's housing for workers is also listed on the National Register of Historic Places.

Today, the old factory site is home to several things. It includes the Charles River Museum of Industry & Innovation. There is also housing for seniors and an arts center called the Ira B. Gordon Center For the Arts.

See also

| Selma Burke |

| Pauline Powell Burns |

| Frederick J. Brown |

| Robert Blackburn |