Carburetor facts for kids

A carburetor is a clever device found in many engines, especially older ones. Its main job is to mix air and fuel perfectly before they enter the engine. Think of it like a chef carefully measuring ingredients for a recipe! This mix is crucial for the engine to run smoothly and powerfully.

Most modern cars and trucks today use something called fuel injection instead of carburetors. However, you can still find carburetors in many small engines. These include things like lawnmowers, generators, and even some motorcycles. Airplanes with piston engines also commonly use carburetors. It's important to know that Diesel engines have always used fuel injection, not carburetors, because they need a very precise way to deliver fuel.

Contents

What's in a Name?

The word "carburetor" comes from an older word, "carburet." This means "to mix with carbon" or "to make a gas richer by adding carbon or similar substances." So, a carburetor does just that: it mixes air with fuel, which is made of carbon-based chemicals. This fuel can be gasoline or other types like LPG.

You might see the word spelled differently! In America, it's usually "carburetor." In places like the UK, it's often "carburettor." People sometimes shorten it to "carb" or "carby" too!

How a Carburetor Works

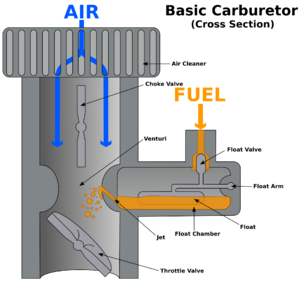

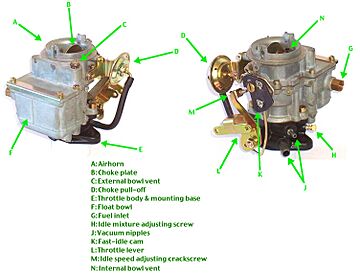

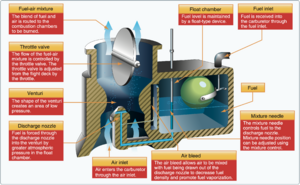

Imagine air rushing into the engine. First, it goes through an air cleaner to remove dirt. Then, it enters the carburetor. Inside, fuel is added to this air. This air-fuel mix then travels into the engine's combustion chamber to be burned. Most engines have one carburetor for all their cylinders. Some powerful engines used to have several carburetors!

The basic idea behind a carburetor is called Bernoulli's principle. It's a bit like how a spray bottle works. When air moves very fast through a narrow part of the carburetor (called a venturi), the air pressure drops. This lower pressure then pulls fuel from a small opening into the fast-moving air stream. It's a clever way to make sure the right amount of fuel mixes with the air.

When you press the gas pedal in a car, you're mostly controlling how much air enters the carburetor. More air means more fuel gets pulled in, which makes the engine go faster!

Carburetors can be designed in different ways based on how air flows through them.

- Updraft carburetors: Air enters from the bottom and leaves through the top. These were common in older engines.

- Downdraft carburetors: Air enters from the top and leaves through the bottom. These became popular from the 1930s, especially in the US.

- Side draft carburetors: Air flows horizontally through the carburetor. These were often seen in Europe.

Different Fuel Systems Inside

Carburetors have several special "circuits" or pathways to make sure the engine gets the right amount of fuel in different situations.

Main Fuel Flow

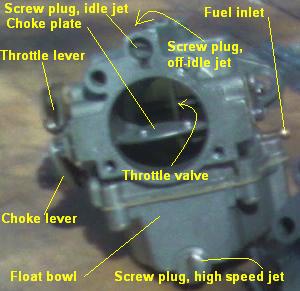

The main part of the carburetor has a narrow section called a venturi. Here, the air speeds up, and its pressure drops. This low pressure pulls fuel from tiny tubes, mixing it with the air. After the venturi, there's a throttle valve, like a butterfly flap. This valve opens and closes to control how much air (and thus fuel) goes into the engine. When you press the gas pedal, you're opening this throttle.

Choke for Cold Starts

Starting an engine in cold weather can be tricky. Fuel doesn't turn into a vapor easily when it's cold. To help, a choke valve partly closes the air entrance to the carburetor. This makes the air pressure even lower, pulling more fuel into the engine. It's like giving the engine an extra rich drink to get it going!

Older cars had a manual choke you pulled on the dashboard. Later, automatic chokes appeared. These would open slowly as the engine warmed up. Leaving the choke on too long wastes fuel and makes the engine run poorly.

Idle Speed Control

When your engine is just idling (running very slowly, like at a stoplight), the main fuel system doesn't work well. That's where the idle circuit comes in. It provides a small, steady amount of fuel to keep the engine running smoothly at low speeds.

Smooth Transitions with Off-Idle

When you first start to press the gas pedal from an idle, the engine needs a little extra fuel to speed up smoothly. The off-idle circuit provides this boost. It helps the engine transition from idling to faster speeds without sputtering.

Power Boost for Hard Work

Sometimes, an engine needs a lot of power, like when climbing a steep hill. A power valve can help here. It's a special valve that opens when the engine is working hard, letting more fuel flow in. This gives the engine an extra kick of power!

Quick Fuel for Acceleration

When you suddenly press the gas pedal, the engine needs fuel right away. But fuel is heavier than air and takes a moment to catch up. The accelerator pump solves this! It's a small pump that squirts a bit of extra fuel directly into the carburetor when you press the pedal. This prevents the engine from hesitating or "stumbling." It can also help "prime" the engine with fuel before a cold start.

How Fuel Gets There

The Float Bowl

Carburetors need a constant supply of fuel. They have a small tank called a "float chamber" or "float bowl." A fuel pump sends fuel to this bowl, or sometimes gravity does the job if the fuel tank is higher. Inside the bowl, a floating valve keeps the fuel level just right, like the float in a toilet tank.

Sometimes, especially in hot weather, the fuel in the float bowl can get too hot and turn into vapor bubbles. This is called 'vapor lock' and can stop fuel from flowing, making the engine stall.

Diaphragm for Tricky Angles

What if an engine needs to work upside down, like in a stunt plane or a chainsaw? A float bowl wouldn't work! In these cases, a diaphragm chamber is used. It has a flexible membrane (a diaphragm) that controls fuel flow, no matter the engine's position. This ensures a steady fuel supply even when the carburetor isn't upright.

More Power: Two and Four Barrels

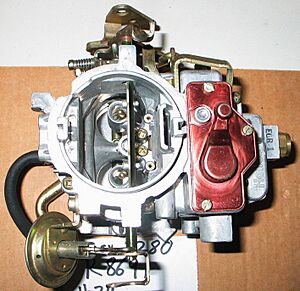

While some carburetors have just one main opening (or "barrel") for air and fuel, many have two or even four! These are called two-barrel and four-barrel carburetors.

Think of it like having extra engines for your car. The "primary" barrels handle normal driving. But when you need a lot of power, like speeding up quickly, the "secondary" barrels kick in. They open up to let even more air and fuel into the engine. This design helps save fuel during regular driving but still gives you plenty of power when you need it.

Powerful engines, especially older V8 engines, often used four-barrel carburetors. Some very high-performance engines even had multiple carburetors, each with several barrels, for maximum power!

A Look at Carburetor History

The idea of mixing fuel and air for an engine is quite old!

- In 1826, an American engineer named Samuel Morey patented an early "gas or vapor engine" that used a carburetor.

- In 1885, German engineers Wilhelm Maybach and Gottlieb Daimler created the first carburetor with a float and a spray nozzle, which is similar to how many carburetors work today.

- Later that year, Karl Benz introduced his famous Benz Patent-Motorwagen, which also used a simple carburetor.

- Hungarian engineers János Csonka and Donát Bánki patented the first carburetor for a stationary engine in 1893.

- The first four-barrel carburetors appeared in 1952 on some General Motors cars.

For many years, carburetors were the standard way to deliver fuel in gasoline engines, especially in the United States. However, by the late 1980s and early 1990s, fuel injection systems started to take over. Fuel injection is more precise and helps engines run cleaner. Even NASCAR, a famous racing series, switched from carburetors to electronic fuel injection after the 2011 season, though they still use four-barrel carburetors in their Xfinity Series.

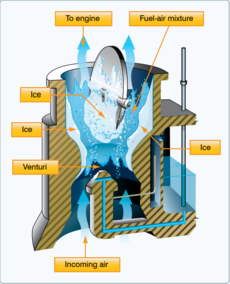

Icing in Aircraft Carburetors

For airplanes, carburetors have a special challenge: ice! When air rushes through the carburetor, its temperature can drop a lot. This, combined with the evaporating fuel, can cause ice to form inside. This is especially a problem when an airplane is descending for landing, as the engine runs at a low speed.

To prevent this, aircraft engines often have a "carburetor heat" system. This system sends warm air, usually from around the engine's exhaust, into the carburetor. Pilots can turn this heat on when there's a risk of icing. While it helps prevent ice, using carburetor heat can slightly reduce engine power because warm air is less dense.

Images for kids

See also

- Bernoulli's principle

- Fuel injection

- List of auto parts

- Venturi effect

| Emma Amos |

| Edward Mitchell Bannister |

| Larry D. Alexander |

| Ernie Barnes |