Conrad Rice Mill facts for kids

Quick facts for kids |

|

|

Conrad Rice Mill

|

|

Rice mill circa 1913

|

|

| Location | 307 Ann Street New Iberia, Louisiana |

|---|---|

| Area | 0.7 acres (0.28 ha) |

| Built | 1914 |

| NRHP reference No. | 82000437 |

| Added to NRHP | November 10, 1982 |

The Conrad Rice Mill is a special place in New Iberia, Louisiana. It's a rice mill that has been owned and run by the same family for a long time. This mill makes different kinds of rice under the Konriko brand. It started way back in 1912, making it the oldest family-owned rice mill in the United States that is still working today!

Two of the buildings at the mill, built between 1914 and 1917, and another from 1930, were added to the National Register of Historic Places on November 10, 1982. This means they are important historical sites.

Contents

How the Mill Started

Philip Amelius (PA) Conrad, who was born in 1882, began growing rice in Avoyelles Parish, Louisiana around the year 1900. He worked with his uncle, Charles Conrad. PA Conrad wanted to have his own business, so he moved to New Iberia. This town is right next to the Bayou Teche, which is a slow-moving river.

He bought land near the Bayou to grow rice. At first, after he harvested his rice, he had to send it about 125 miles by steamboat all the way to New Orleans to be processed. This was because there were no rice mills nearby. After growing several crops, he decided to build his own small rice mill on his land in 1910. This way, he didn't have to ship his rice so far away.

In 1912, he moved his mill to its current spot at 307 Ann Street in New Iberia. He named his new business the Conrad Rice Milling and Planting Company. He bought more land and moved his rice fields to the other side of the Bayou. Having the rice fields near the Bayou Teche was very important because rice needs a lot of water to grow. Over the years, the company bought even more land for farming, eventually owning 575 acres!

Early Rice Farming Methods

In the early days of the mill, rice farming was done mostly by hand, without big machines. Farmers used mules to pull tools that prepared the land. After spreading the seeds by hand, they built small dirt walls called levees. These levees were just tall enough to hold about 1 to 1.5 inches of water in the fields.

Water was brought from the Bayou Teche, which could be up to three miles away! They built a special system to do this. Water pumps pulled water from the bayou up to a high trough, about twelve feet above the water. This trough then sloped down for over 700 feet to a street-level channel called a flume. Gravity helped the water flow through this flume to the fields. The flume even went under parts of New Iberia by using old steam boilers as tunnels!

Two powerful pumps were used at the bayou. They could pump 1100 to 1300 gallons of water every minute! It took about a week to flood the fields the first time. They had to keep pumping water to keep the fields wet until the rice plants grew tall enough. Then, they would open the levees to drain the water so the young plants wouldn't get hurt. Once the plants were strong, they flooded the fields again until the rice was almost ready to harvest.

Rice was usually planted in the spring, around Easter, and harvested in August. It took about 150 days for the rice to grow, but newer types of rice grew faster, in about 120 days. All this work, from watering to harvesting, needed 20 to 40 workers!

The rice stalks were cut by hand and gathered into bundles called shocks. These shocks were left in the field for 2 to 3 days to dry. Then, a tractor-powered thresher separated the rice grains from the stalks right there in the field. After that, the rice was taken by wagon to the mill, sometimes several miles away. At the mill, the rice was dried even more using a special dryer. This reduced the moisture in the rice from about 25% to 18%, which made it easier to mill.

How Farming Became Mechanical

Machines started to be used in the 1930s. Tractors first took the place of mules for preparing the land. The first tractors were from McCormick-Deering/International Harvester. They had steel wheels and had to be started by hand cranking!

Mechanical harvesting didn't start until just before World War II. That's when a McCormick Reaper was changed to work with rice. This machine cut and bundled the rice stalks. Workers still gathered these bundles into shocks for drying in the field. A mechanical thresher then replaced the old tractor-driven one. Also, new rice dryers allowed the rice to be dried right in the field. This helped protect the rice from birds and rain.

In 1946, amazing machines called combines were introduced. These machines could do both cutting and threshing at the same time! They removed the rice from the stalk right in the field. This meant all the drying could happen at the mill after the rice was off the stalk.

How Rice Was Milled

The mill built on St. Ann Street in 1912 was three stories tall. This was smart because it used gravity to move the rice through different steps. Rice would start on the third floor and move down to the second and first floors as it was processed. Then, it would be lifted back up for the next stage.

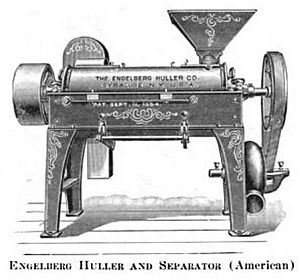

The first step was when rice was brought by an elevator to a storage bin on the third floor. From there, it went into two large, five-foot-wide stones that removed the outer shell of the rice. Next, it went into a huller to take off the bran layer. After that, a "brush" polished the rice. In those days, very polished white rice was popular. Today, the first step is often skipped to keep the healthy bran layer on the rice.

After the "brush," the rice went into a machine called a "trumble." This machine added a coating of sugar (sucrose) and talcum powder. This is why old instructions often said "wash before cooking"! Finally, the rice was moved to scales to be weighed and put into bags. At first, it was sold in large 100-pound sacks. Later, it was sold in smaller bags of 10, 25, and 50 pounds.

The machines that removed the outer shell were called Engelberg hullers, made in Germany. Before electric motors, these hullers were powered by huge 150-horsepower steam engines. These engines got their power from big boilers. A complex system of belts and pulleys transferred the power from the engines to the hullers. In 1951, electric motors were finally brought in, replacing the old steam engines.

Owners and Workers

PA Conrad's oldest son, Philip Odell (PO) Conrad, joined his father in the business after high school in 1920. He worked there until he passed away in 1945. PA's second son, Allen Conrad, started working at the mill in 1925 after finishing boarding school. He began as a farm hand. PA's third son, Julian, also worked as a farm hand during his school years. After graduating from business college, he joined the company as the bookkeeper, managing the financial records.

PA Conrad retired in 1940 to open a different business, but he still helped out at the mill as an advisor until he passed away in 1961. During World War II, the mill lost all its full-time workers. Since there weren't many machines back then, family members and day laborers had to work hard to keep the mill running.

The person who worked at the mill the longest was Leander "Gutchie" Viltz. Leander grew up with Allen and Julian. He started working at the mill when he was just six years old and worked there for an amazing 72 years!

Recent History of the Mill

Growing rice on the farm stopped in 1968. Part of the farm land was sold to build new neighborhoods in New Iberia. Other housing developments were built near the old irrigation system. However, the milling of rice continued, and it still does today! When the Conrad family owned the mill, they only made white rice, which they sold to local grocery stores.

In 1975, Michael Davis bought the mill from the Conrad family after Allen and Julian Conrad retired. Mr. Davis added more types of rice, like brown rice and flavored rice. The business also started making other food products, such as local seasonings, spices, sauces, marinades, and snacks. They added new brands like HOL GRAIN and QUIGGS and started selling their products all over the United States and Canada.

The Konriko Brand Name

In the 1950s, the company tried to trademark their brand name as "Conrico." This name came from "Conrad Rice Company." However, the US Patent and Trademark Office said no. This was because another company, the California Rice Cooperative, had a very similar trademark. So, the name was changed to Konriko, which was accepted. This is the brand name the mill is known by today!

See also

- Rice Mill Lofts: A former rice mill building in New Orleans.

- National Register of Historic Places listings in Iberia Parish, Louisiana