Foundry facts for kids

A foundry is a special factory where metal objects are made. These objects are called castings. To make them, workers melt metal until it's liquid. Then, they pour the hot liquid metal into a mold. After the metal cools down and becomes solid, they remove the mold. The most common metals used are aluminum and cast iron. But foundries also work with bronze, steel, magnesium, copper, tin, and zinc.

Contents

How Castings Are Made

Making metal castings involves several important steps. Each step helps turn raw metal into a finished product.

Melting the Metal

Melting happens inside a special oven called a furnace. Workers put different materials into the furnace. These include new, pure metal, old metal scraps from other factories, and even leftover metal from inside the foundry. They also add special ingredients called alloying elements. These elements help create the right mix for the metal.

First, the metal melts. Then, it's "refined" to remove any unwanted gases or tiny bits that could cause problems. Workers also adjust the metal's chemistry. This makes sure it has the right properties. Finally, the melted metal is poured into a transport container, like a large bucket called a ladle.

Types of Furnaces

Foundries use different types of furnaces to melt metal. These furnaces are like big, strong containers lined with heat-resistant materials. They hold the metal and provide the energy to melt it. Some modern furnaces include electric arc furnaces, induction furnaces, and cupolas.

The type of furnace depends on the metal and how much is being made. For example, furnaces for zinc or tin might only need to reach about 327° Celsius. These use electricity, propane, or natural gas. But for metals like steel or nickel, furnaces need to get much hotter, over 1600° Celsius! These high-temperature furnaces often use electricity or a fuel called coke.

Most foundries focus on one type of metal. An iron foundry might use a cupola or induction furnace. A steel foundry would use an electric arc or induction furnace. Aluminum foundries often use electric or gas-heated furnaces.

Removing Gas from Aluminum

When working with aluminum alloys, it's important to remove hydrogen gas from the liquid metal. If there's too much hydrogen, the finished casting will have tiny holes. These holes can make the metal weaker.

To remove hydrogen, workers bubble gases like argon or nitrogen through the melted aluminum. As the bubbles rise, they collect the dissolved hydrogen and carry it to the surface. Foundries also have tools to measure how much hydrogen is in the metal.

Making the Mold

Before pouring, a mold must be made. This mold is shaped like the part that will be cast. The mold is created using a "pattern." This pattern can be made from wax, wood, plastic, or metal. Simple parts might use a single-piece pattern. More complex parts use a "split pattern" with two sections: a top part called a "cope" and a bottom part called a "drag."

The line where the cope and drag meet is called the parting line. To make it easy to remove the pattern without breaking the mold, the edges of the pattern are slightly angled. This angle is called "draft."

Different ways of making molds include:

- Sand casting: Uses sand mixed with a binder.

- Lost-foam casting: Uses a foam pattern that melts away when hot metal is poured in.

- Investment casting: Uses a wax pattern that is melted out, leaving a ceramic mold.

- Die casting: Uses a reusable metal mold.

Pouring the Metal

Once the mold is ready, the hot, liquid metal is poured into it. This can be done by gravity, or sometimes with help from a vacuum or pressurized gas. Many modern foundries use robots or automatic machines to pour the metal. In the past, workers poured the metal by hand using large ladles.

Shakeout

After the metal cools and becomes solid, it's time to remove it from the mold. If it's a sand mold, workers might shake or tumble the mold. This helps free the new metal casting from the sand. The casting is still attached to extra metal parts, like channels that guided the liquid metal.

Removing Extra Metal

Next, workers remove the extra metal parts. These include the "runners," "gates," and "risers." These are the channels and reservoirs that helped the liquid metal flow into the mold. They can be cut off using special torches, saws, or ceramic blades. Sometimes, for certain metals, these extra pieces can simply be broken off with a hammer.

The amount of extra metal can be more than half of the total metal poured! This leftover metal is melted down again and reused. Foundries try to design their molds to reduce this waste.

Cleaning the Surface

After removing the extra metal, some sand or mold material might still stick to the casting. To clean this off, the surface is blasted. This means tiny pieces of material, like steel or glass beads, are shot at the casting. This knocks off any stuck-on bits. This process is called cleaning, bead blasting, or sand blasting.

Finishing the Casting

The last step is to make the casting perfect. This often involves grinding, sanding, or machining the part. These steps help the casting reach the exact size, shape, and smoothness needed.

Any leftover gate material is usually ground or sanded off. Then, parts that need very precise measurements are machined. Many castings are machined using CNC machines. These machines are very accurate and repeatable. Some castings are used without any machining at all.

Some foundries offer extra services. They might paint the castings to prevent rust or make them look better. They might even put several castings together to make a complete machine or a part of one. Some foundries also weld castings together.

More and more, robots are used for finishing castings. This means humans don't have to do the hard work of grinding or breaking off extra pieces. Robots can work faster, reduce injuries, and make sure every casting is finished exactly the same way. They can work with many different metals, like iron, bronze, and aluminum.

Images for kids

-

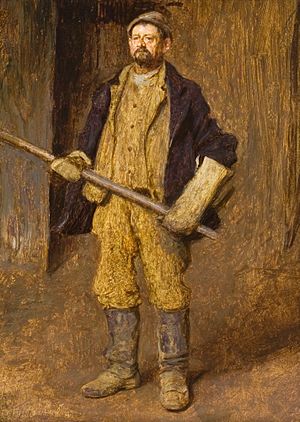

From Fra Burmeister og Wain's Iron Foundry, by Peder Severin Krøyer, 1885.