Francis turbine facts for kids

The Francis turbine is a special type of water turbine. It pulls water in from the sides and pushes it out through the middle. This design combines two ways water can flow: radial (like spokes on a wheel) and axial (straight down). Francis turbines are the most common water turbines used today. They are super efficient, turning more than 95% of the water's energy into power!

This turbine was named after a British-American engineer named James B. Francis. He created a new turbine design in 1848. By around 1920, his improved design became known as the Francis turbine.

Francis turbines are mainly used to make electricity. The power they produce can range from small amounts (a few kilowatts) to huge amounts (up to 1000 megawatts). They work best when the water falls from a height (called the head) of about 100 to 300 meters (330 to 980 feet). The pipes that carry the water, called penstocks, are usually between 1 and 10 meters (3 to 33 feet) wide.

These turbines spin very fast, from 70 to 1000 times per minute. A special gate, called a wicket gate, controls how much water flows through the turbine. This helps manage how much electricity is made. Francis turbines are often set up with a vertical shaft. This keeps the water away from the generator and makes them easier to install and maintain.

Contents

How Francis Turbines Were Developed

People have used water wheels for over 1,000 years to power mills. But these old water wheels were not very efficient. In the 1800s, new water turbines were invented that were much better. These new turbines started to replace water wheels. They even competed with steam engines in places where water power was available.

Later in the 1800s, electric generators were invented. Turbines became a perfect way to power these generators and make electricity from flowing water.

In 1826, a French engineer named Benoit Fourneyron created a very efficient water turbine. It was 80% efficient! Water flowed out from the center of his turbine, making it spin. Around 1820, another French engineer, Jean-Victor Poncelet, designed a turbine that pulled water inwards.

In 1848, James B. Francis worked as a chief engineer in Lowell, Massachusetts. This city had many textile factories powered by water wheels. Francis improved on the designs of earlier turbines. He used scientific ideas and tested his designs carefully. This helped him create a very efficient turbine. His new math and drawing methods also made turbine design much better. His smart ways of calculating helped engineers design super-efficient turbines. These turbines could perfectly match the water flow and pressure at any location.

Main Parts of a Francis Turbine

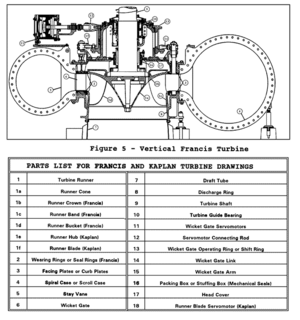

A Francis turbine has several important parts that work together:

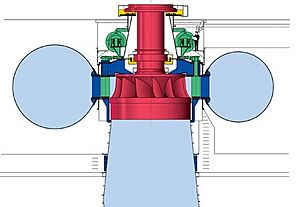

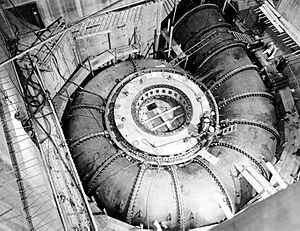

Spiral Casing

The spiral casing is a big, snail-shaped pipe that wraps around the spinning part of the turbine. It's also called the volute casing or scroll case. This casing has many openings that let water flow into the turbine's blades. As the water moves through this casing, its pressure energy turns into movement energy (kinetic energy). The casing gets smaller as it goes around, which helps keep the water's speed constant as it enters the blades.

Guide and Stay Vanes

These are special blades that sit inside the spiral casing. Their main job is to turn the water's pressure energy into kinetic energy. They also make sure the water hits the main spinning blades at the perfect angle.

Runner Blades

These are the most important part of the turbine. They are the spinning blades that the water hits. When the water pushes against these blades, it creates a turning force (torque). This force makes the turbine's shaft spin. Engineers pay close attention to the angles of these blades. The angles are very important for how much power the turbine can make.

Draft Tube

The draft tube is a pipe that connects the bottom of the spinning blades to the place where the water leaves the turbine. This is called the tail race. The main job of the draft tube is to slow down the water as it leaves the turbine. This helps save energy that would otherwise be lost. It also allows the turbine to be placed higher than the water level outside, without losing much power.

How a Francis Turbine Works

The Francis turbine is a reaction turbine. This means that water comes into the turbine under very high pressure. The turbine blades then take energy from this high-pressure water. Part of the water's energy is used up as its pressure changes while it moves over the blades. The rest of the energy is taken by the spiral casing.

When the water leaves the turbine, it has very little speed or energy left. The draft tube (the exit pipe) is shaped to help slow the water down even more. This also helps to recover some of the pressure.

Where Francis Turbines Are Used

Francis turbines can be designed to work with many different water heights and flows. Because they are so flexible and efficient, they are the most popular type of turbine in the world. They can work with water falling from 40 to 600 meters (130 to 2,000 feet) high. They can produce electricity from just a few kilowatts to a massive 1000 megawatts.

Large Francis turbines are custom-made for each location. This helps them work with the specific water flow and height at that spot. They are usually more than 90% efficient, sometimes even up to 99%!

Unlike some other turbines, the Francis turbine always works best when it is completely full of water. The turbine and its exit channel can even be placed lower than the lake or sea level outside. This helps prevent a problem called cavitation, which can damage the turbine.

Besides making electricity, Francis turbines can also be used for pumped storage. In this system, the turbine acts like a pump. It uses extra electricity (when demand is low) to push water uphill into a reservoir. Then, when people need more electricity (during peak demand), the water flows back down. It spins the turbine (which now acts as a generator) to create power. This is a great way to store extra electricity for later use!

See also

- Draft tube

- Evolution from Francis turbine to Kaplan turbine

- Hydropower

- Jonval turbine

- Kaplan turbine

- Pelton wheel

- Sensor fish, a device used to study the impact of fish travelling through Francis and Kaplan turbines

| Lonnie Johnson |

| Granville Woods |

| Lewis Howard Latimer |

| James West |