General Electric Specialty Control Plant facts for kids

|

General Electric Specialty Control Plant

|

|

|

|

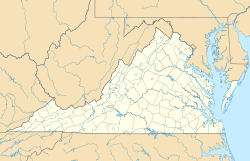

| Location | 1 Solutions Way, Waynesboro, Virginia |

|---|---|

| Area | 25.5 acres (10.3 ha) |

| Built | 1927, 1953, 1960, 1969 |

| Built by | J. A. Jones Construction Company |

| Architect | Whitman, Requardt & Associates |

| NRHP reference No. | 12000180 |

Quick facts for kids Significant dates |

|

| Added to NRHP | March 29, 2012 |

The General Electric Specialty Control Plant is a large, historic factory in Waynesboro, Virginia. This huge factory complex covers about 115 acres (47 ha) of land. It includes several important buildings and structures. These include a main plant building, a water tower, and even an old airplane hangar from around 1927.

The property used to be an airport before General Electric (GE) bought it in 1953. This Waynesboro plant was one of many new factories GE opened across the country. It became a key place for creating new technologies. These breakthroughs helped with America's military efforts, space travel, and even early computer technology. The factory was later sold to another company called GENICOM in 1983.

The street where the plant is located has changed names over the years. It was first General Electric Drive, then GENICOM Drive. Today, part of it is called Solutions Way. In 2000, GENICOM faced financial trouble. The building was then sold to Solutions Way Management. This company now rents out parts of the factory to other businesses. The plant was added to the National Register of Historic Places in 2012. This means it is recognized as an important historical site.

Contents

How the Plant Started

In the early 1950s, the General Electric Company was very centralized. Most of its factories were in just a few big cities. Then, under its president, Ralph Cordiner, GE decided to change. They wanted to spread out their operations. This meant dividing larger business groups into smaller departments. New plants were built in many different places.

The original Industrial Control Division was in Schenectady, New York. It was split into four new departments. Each of the first three focused on a specific product type.

- The Industry Control Department made control systems for big industries. This included systems for cranes, steel mills, and marine uses. It was located in Salem, Virginia.

- The General Purpose Control Department made smaller control parts. These included relays and contactors for general industrial use. It was located in Bloomington, Illinois.

- The Appliance Control Department made control systems for home products. This included parts for refrigerators and oil burners. It was located in Morrison, Illinois.

The Specialty Control Department came to Waynesboro, Virginia. This department handled all the other different products from the original division. These were products that couldn't easily fit into the other three new departments.

Building and Growing the Plant

Construction Begins

In 1953, GE bought the old Waynesboro airport. It was a 75-acre property. About 43 acres were used for the new plant, parking lots, and landscaped areas. Construction of the new factory began quickly. By the summer of 1954, they were ready to start making products. Some managers moved from Schenectady, and about 10 local women were hired to begin production.

Early Planning Team

A small group of people moved from Schenectady to Waynesboro in 1954. They were the first planning team for the new plant. This group helped get everything ready. They oversaw the start-up and the transfer of other employees to Waynesboro.

- Dr. L. T. Rader, General Manager

- Maggy Fitzgibbons, Secretary to Mr. Rader

- Ernie Hutton, Engineering

- Charles Hughes, Purchasing

- Cyril Lee, Planning

- Joe Ponzillo, Manufacturing

- Fred Curto, Buildings and Grounds

- Bill Walker, Laboratory

Operations Start in 1954

In its first full year, the new department hired 400 factory workers. Most of these people had never worked in a factory before. For many, it was their very first job.

Waynesboro and the nearby areas saw a big building boom in 1955. Over 140 families from GE began moving to the area. They came to work at the new factory. New homes quickly filled areas like Cortland Street and Club Court. Local families were very welcoming to the newcomers. They helped them settle into their new homes. Over the next few years, many new churches were built. A new hospital also opened. The shopping areas in Waynesboro also saw big improvements.

Plant's Impact on Jobs

The GE plant was a major employer in the area. At its busiest in the late 1970s, it employed 3200 people. This made GE one of the largest employers in the Waynesboro area. Many people found their entire careers working at the plant. The plant had a big impact on the local economy.

Improving the Plant's Access

The original entrance to the new plant was a narrow road. It crossed the railroad tracks. GE wanted a bridge built over the railroad. This would make it safer for the many vehicles coming to the plant each day. The bridge was built within two years.

Wide Range of Products

The Waynesboro plant made many different products. This shows how much technical skill was at the factory. The staff knew about almost every scientific area. Here are some of the products made:

- Special relays for aerospace and military uses.

- Numerical Control Systems for machine tools. These systems used punched tape or cards to control machines. Some were even controlled by computers.

- Adjustable speed drives for different industries. These controlled the speed of machines.

- Regulators for electrical power systems.

- Photoelectric devices for many uses. These included detectors for tiny holes and controls for speed.

- Hot-box detectors for finding overheated parts on railroad cars.

- Aircraft and military products. This included power supplies for the Apollo Lunar Module that went to the moon.

- Automation systems for machinery. These included weighing and inspection systems.

- Gauges to measure the thickness of steel sheets using nuclear radiation.

This wide variety of products helped the plant stay strong. It could handle the ups and downs of business better than other companies. This meant fewer layoffs and more stable jobs for the local area. The Specialty Control Department was the only GE part that made a profit in its first year after moving.

Major Expansion in 1960

In 1960, the plant had a big expansion. They added more office and manufacturing space. A new auditorium and cafeteria were also built. They also added a "white room." This was a super clean area for putting together sensitive relays.

The Waynesboro GE plant continued to grow. By the late 1960s, a new product line called 'Terminet' began. A special team developed these new printer terminals. They used new solid-state technology. These printers competed with other companies in the computer and business data field. The belt printer technology they created was very successful. It was used in printers for almost 20 years.

Dividing the Department in the 1970s

In the early 1970s, the Specialty Control Department was split. The growing numerical control group became its own department. It was called the Numerical Equipment Control Department.

Over the years, the Specialty Control Department had five different general managers.

Moving to Charlottesville in 1979

By 1979, the GE-Waynesboro plant was very full. Because of this, the Numerical Equipment Control Department moved. It went to a new facility north of Charlottesville, Virginia. There, it joined a larger division.

Plant Changes and Closure

Product Lines Move Out

By the late 1960s, the aircraft product business had moved to other GE plants. By 1974, the adjustable speed drives business also moved. The photoelectric business was taken over by another GE department. Other power system parts also moved to different GE locations.

This meant that only the Terminet printers and the relay business were left at the Waynesboro plant. The name of the department changed to Data Communications Products Department.

New Printer Technology

In the late 1970s, GE tried to develop a new type of printer. This printer would not use impact, like laser printers. The goal was to create a printer that could print 8000 lines per minute. At that time, most printers did 300 to 600 lines per minute. This new technology was very advanced. However, the company couldn't find a market for it, and the project stopped.

Relays and High-Speed Printers: The Start of Genicom

Two product lines at Waynesboro were difficult for GE to manage. For years, GE thought the relay business would end. Also, in the early 1980s, GE didn't see a long-term future for high-speed impact printers. These products didn't fit into GE's main business plans anymore.

In 1981, GE decided to sell both the relay and printer businesses. A group of managers bought them in October 1983. A new company was formed called Genicom Corporation. Genicom focused on the printer business. Genicom later sold the relay business in the early 1990s.

Genicom's Growth and Changes

Genicom was very successful at first. Its stock became public in 1987-88. However, new printer technologies like laser and ink jet printers started to take over. It became harder for Genicom to compete. Genicom also started a successful service business. This business serviced all types of printers. It grew very large and had sales of $400 million at its peak.

Genicom's Bankruptcy

Genicom tried to merge with other companies, but these efforts failed. On March 10, 2000, Genicom declared bankruptcy. In 2001, a group of investors bought the printer division. It was renamed Genicom LLC. It was then resold again in 2003.

A small part of the printer business continued under the name Genicom LP. Another company, Northrop-Grumman, took over the parts and service for existing Genicom printers.

Tally-Genicom Merger

In 2003, Tally and the remaining Genicom company merged. They formed Tally-Genicom. This new company continued to design and support dot-matrix printers. They used a part of the old General Electric plant.

Solutions Way Management Today

Solutions Way Management, LLC, bought the former GE property in 2001. They bought it as part of the Genicom bankruptcy. Today, they operate the property as a place for new businesses. They provide manufacturing space and support services for these companies.

Environmental Efforts

General Electric and GENICOM used to make circuit boards at the site. This process created waste materials. These wastes caused some groundwater contamination. General Electric has taken responsibility for this. They now operate a system that pumps and treats the water to clean it up.