Laser cutting facts for kids

Laser cutting is a cool technology that uses a super strong beam of light, called a laser, to cut through different materials. Think of it like a super-sharp, super-hot knife made of light! This method is often used in factories to make things, but now it's also popular in schools, small businesses, and for hobbies.

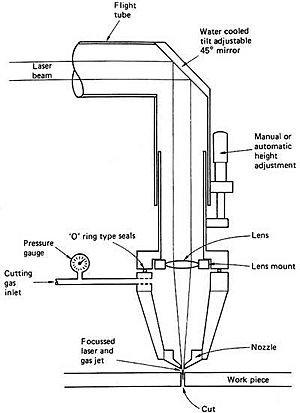

A laser cutter works by shining a powerful laser beam onto the material. Special mirrors and lenses guide this beam. A computer system, called CNC (which stands for Computer Numerical Control), tells the laser exactly where to go, following a pattern. When the focused laser beam hits the material, it gets so hot that the material either melts, burns, turns into vapor, or is blown away by a jet of gas. This leaves a very clean and smooth cut edge.

Contents

How Laser Cutting Started

The first machine that used a laser for cutting was made in 1965. It was used to drill tiny holes in diamond tools. This was done by the Western Electric Engineering Research Center.

A few years later, in 1967, British scientists found a way to use lasers with oxygen gas to cut metals. By the early 1970s, this technology was being used to cut strong metals like titanium for airplanes. Around the same time, a type of laser called a CO2 laser was used to cut things that weren't metal, like textiles (fabrics). Back then, CO2 lasers weren't strong enough to cut through metals easily.

How the Process Works

The laser beam is usually focused into a tiny spot by a special lens. This spot can be smaller than a grain of sand! Because the spot is so small, it can make very thin cuts.

To start cutting in the middle of a material, the laser first makes a small hole. This is called "piercing." The laser uses short, strong bursts of energy to slowly make this hole. For example, it can take 5 to 15 seconds to pierce through a thick piece of stainless steel.

One great thing about laser cutting is that it's very precise. The laser beam doesn't get dull like a normal cutting tool. This means the cuts are always accurate. Also, the laser only heats a very small area, so there's less chance of the material bending or changing shape from the heat. Some materials are also very hard or impossible to cut with regular tools, but a laser can do it!

When cutting metals, laser cutting is often more precise and uses less energy than another method called plasma cutting. However, plasma cutters can usually cut much thicker metal than most industrial lasers. But new, more powerful laser machines are catching up!

Different Types of Lasers

There are three main types of lasers used for cutting:

- CO2 lasers: These are great for cutting, drilling holes, and engraving many materials like titanium, stainless steel, aluminum, plastic, wood, and paper.

- Neodymium (Nd) lasers: These are used for making holes and when you need a lot of energy in short bursts.

- Nd:YAG lasers: These are similar to Nd lasers but are used when you need very high power for drilling and engraving.

Both CO2 and Nd/Nd:YAG lasers can also be used for welding (joining materials together).

CO2 lasers work by passing electricity through a mix of gases. YAG lasers are mostly used for cutting and marking metals and ceramics.

The laser machine needs to stay cool, so it often uses water that circulates through a cooling system.

Water-Jet Guided Lasers

A special type called a laser microjet uses a laser beam combined with a low-pressure water jet. The water jet acts like a guide for the laser beam, similar to how light travels through a fiber optic cable. The water also helps to clean away debris and cool the material as it's being cut. This method allows for very fast and precise cuts.

Fiber Lasers

Fiber lasers are a newer type of laser that are becoming very popular for cutting metal. Unlike CO2 lasers that use gas, fiber lasers use a special glass fiber to create and amplify the laser beam. They produce a super tiny spot, which is great for cutting shiny metals like copper and brass.

Fiber lasers have many benefits:

- They cut very quickly.

- They use less energy, which saves money on electricity bills.

- They are very reliable and need less maintenance.

- They can cut reflective metals that are hard for other lasers.

- They help increase how much you can produce because they are efficient.

How Lasers Cut Materials

Lasers can cut materials in different ways, depending on what they are cutting.

Vaporization Cutting

In this method, the laser beam heats the material's surface so fast that it turns directly into a gas (vapor). This creates a hole that quickly gets deeper. Materials like wood, carbon, and some plastics are often cut this way.

Melt and Blow

This method, also called fusion cutting, uses a high-pressure gas to blow away the material once it's melted by the laser. The laser heats the material just enough to melt it, and then the gas jet pushes the melted material out of the way. This method is usually used for cutting metals.

Thermal Stress Cracking

This is used for brittle materials like glass. The laser heats a small spot, causing it to expand. This expansion creates a tiny crack. By moving the laser beam, the crack can be guided across the material, cutting it very quickly.

Reactive Cutting

Reactive cutting is also known as "flame cutting." It's similar to using an oxygen torch, but the laser beam acts as the spark to start the burning. This method is mostly used for cutting thick carbon steel and can cut very thick metal plates with less laser power.

Accuracy and Smoothness

Laser cutters are incredibly accurate. They can place the laser beam within 10 micrometers (that's 0.00001 meters!) of where it's supposed to be.

The smoothness of the cut edge depends on the material's thickness, the laser's power, and how fast it cuts. Generally, thicker materials result in a slightly rougher edge, while more laser power and slower cutting speeds can make the edge smoother. Laser cutting can achieve very tight tolerances, often within 0.025 millimeters.

Types of Laser Cutting Machines

There are three main ways industrial laser cutting machines are set up:

- Moving Material Systems: In these machines, the laser head stays still, and the material moves underneath it. This keeps the distance between the laser and the material constant. These machines often have fewer parts to deliver the laser beam but can be slower.

- Hybrid Systems: These machines have a table that moves in one direction (like back and forth), and the laser head moves in the other direction (like side to side). This helps keep the laser beam's path length more consistent.

- Flying Optics Systems: In these machines, the material stays still, and the laser head moves over the material in both directions. These are usually the fastest type of laser cutters, especially for thinner materials. They are great because you don't need to clamp the material down.

Some advanced machines can even cut materials that are already shaped, not just flat sheets. These are called five or six-axis machines.

Pulsing the Laser

Most industrial lasers can either fire a continuous beam or send out short, powerful bursts of energy, called "pulses." Pulsing is very useful for making holes or when you need to cut very slowly. If the laser beam were continuous in these cases, it might melt too much of the material.

Some lasers use "double pulse" technology. This means they send out two pulses very quickly. The first pulse removes material, and the second pulse helps prevent the melted material from sticking to the sides of the cut.

How Much Power Lasers Use

One downside of laser cutting is that it uses a lot of electricity. The efficiency of industrial lasers can vary, but they can use a lot of power. The amount of power needed depends on the type of material, its thickness, and how fast you want to cut.

| Material | Material thickness | ||||

|---|---|---|---|---|---|

| 0.51 mm | 1.0 mm | 2.0 mm | 3.2 mm | 6.4 mm | |

| Stainless steel | 1000 | 1000 | 1000 | 1500 | 2500 |

| Aluminium | 1000 | 1000 | 1000 | 3800 | 10000 |

| Mild steel | − | 400 | − | 500 | − |

| Titanium | 250 | 210 | 210 | − | − |

| Plywood | − | − | − | − | 650 |

| Boron/epoxy | − | − | − | 3000 | − |

Speed of Cutting

The speed at which a laser can cut depends on many things, like the laser's power, the material's thickness, and the type of material. Industrial laser systems can cut carbon steel from about 0.5 millimeters to 13 millimeters thick. For many jobs, a laser can cut up to thirty times faster than traditional sawing!

| Workpiece material | Material thickness | |||||

|---|---|---|---|---|---|---|

| 0.51 mm | 1.0 mm | 2.0 mm | 3.2 mm | 6.4 mm | 13 mm | |

| Stainless steel | 42.3 | 23.28 | 13.76 | 7.83 | 3.4 | 0.76 |

| Aluminium | 33.87 | 14.82 | 6.35 | 4.23 | 1.69 | 1.27 |

| Mild steel | − | 8.89 | 7.83 | 6.35 | 4.23 | 2.1 |

| Titanium | 12.7 | 12.7 | 4.23 | 3.4 | 2.5 | 1.7 |

| Plywood | − | − | − | − | 7.62 | 1.9 |

| Boron / epoxy | − | − | − | 2.5 | 2.5 | 1.1 |

See also

In Spanish: Corte con láser para niños

In Spanish: Corte con láser para niños

- 3D printing

- Drilling

- Laser ablation

- Laser beam machining

- Laser beam quality

- Laser converting

- Laser drilling

- Laser engraving

- List of laser articles

- Mirror galvanometer

- Water jet cutter