Mechanization facts for kids

Mechanization is when we start using machines to do work that people or animals used to do by hand. Think of it as upgrading from doing things by yourself to using tools and machines.

A machine is built to perform specific tasks. It needs a power source, like electricity or an engine, and something to work on. Machines act as a go-between, connecting the power to the job that needs to be done.

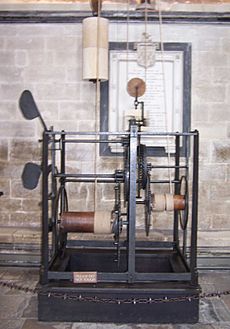

In simple terms, mechanization means using more complex machines, not just basic hand tools. For example, a clock with gears is a machine, but a simple hammer isn't. When factories started using electricity, mechanization often meant using machines powered by motors. When machines can do many tasks by themselves, it's called automation.

Contents

History of Machines

Early Machines

People have used machines for a long time!

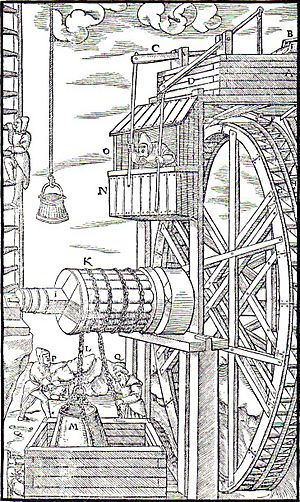

- Water wheels were used by the Romans to grind grain and lift water for farms.

- In China, water-powered bellows helped blast furnaces as early as 31 AD.

- By the 1200s, water wheels powered sawmills and machines called trip hammers. These hammers crushed ore or helped make paper.

Clocks were some of the first really complex machines. Clockmakers were very important. They invented tools to cut gears and screws. Clocks were also among the first items to be mass-produced, starting around 1830.

People also improved how gears worked. Better gear designs meant less wear and more power. By the 1700s, special gear designs, like "involute gears," were used. Machines that could cut gears also appeared around this time.

The Industrial Revolution

The Industrial Revolution was a huge step forward for machines. It started in the 1700s, mostly with machines for making clothes.

- The Newcomen steam engine was first used in 1712 to pump water out of mines.

- Machines like the spinning jenny (1764) and water frame (1768) made it much faster to spin thread.

Making these new textile machines needed lots of metal parts. This led to the invention of many machine tools from the late 1700s to the mid-1800s. Slowly, iron replaced wood in machine parts. By the 1840s, "self-acting" machine tools were invented, meaning they could do more on their own.

Machines also changed farming.

- The seed drill, invented around 1700, helped farmers plant seeds more evenly. This meant more crops and less wasted seed.

- In 1817, the first bicycle was invented in Germany.

- Horse-drawn machines like reapers (for cutting crops) and threshing machines (for separating grain) appeared in the 1800s.

- Later, steam engines powered threshing machines and even early tractors.

- In the 1900s, tractors started using internal combustion engines. By the 1930s, combine harvesters could do both threshing and harvesting.

In the mid-1800s, new systems using water (hydraulic) or air (pneumatic) pressure were used to power machines. These could move heavy objects or control parts of a machine. For example, power steering in cars uses hydraulics. Compressed air is often used to open and close valves in factories.

The 1900s and Beyond

By the early 1900s, machines could do very complex jobs that used to need skilled workers.

- A machine invented in 1905 could make glass bottles. This machine replaced many human workers and led to bottles being made much faster and cheaper.

After 1900, factories started using electricity. Electric motors and controls made machines even more powerful and precise. This meant almost everything we use today could be made by machines.

Types of Mechanization

In factories, machines replaced hand methods for making goods.

- Prime movers are machines that turn energy (like heat or wind) into movement. This includes car engines, jet engines, water wheels, windmills, and steam engines.

- Transportation equipment like trains, cars, trucks, and airplanes are also types of machinery.

- Inside factories and warehouses, material handling equipment (like forklifts) replaced people carrying things by hand.

In mining, big power shovels replaced picks and shovels. Old water-powered trip hammers that crushed ore were replaced by modern crushers and ball mills.

Bulk material handling systems move large amounts of things like coal, sand, or grain.

Construction equipment includes cranes, concrete mixers, and power tools.

Powered Machines

Today, "powered machinery" usually means machines run by electric motors or internal combustion engines (like in cars). Before the early 1900s, "powered" often meant using steam, water, or wind.

Many early machines were hand-powered. But by the early 1800s, most switched to water or steam power.

Before factories had electricity, power was often sent to machines using a long spinning rod called a line shaft. When factories got electricity, each machine could have its own motor. This was called "unit drive." It made factories more organized and allowed different machines to run at different speeds. It also made machines much faster.

A step beyond just mechanization is automation. Early machines, like the glass bottle blowing machine from the 1890s, still needed a lot of human help. But by the 1920s, fully automatic machines needed much less human attention.

Machines in the Military

In the military, "mechanized" means using armored vehicles (like tanks or armored personnel carriers) to move troops and fight from them. "Motorized" means troops ride in vehicles (like trucks) to get to a battle, but then they get out and fight on foot. So, a self-propelled artillery unit (which moves and fires from a vehicle) is mechanized, but a towed artillery unit (which is pulled by a truck) is motorized.

Machines vs. Human Work

Machines are much more powerful and efficient than humans for many tasks.

- A human worker is only about 1% to 5.5% efficient at turning food energy into work.

- Internal combustion engines are about 20% efficient, and some very large diesel engines can be almost 50% efficient. Electric motors can be over 90% efficient.

Machines can also do a lot more work for less money. For example, burning just one liter of fuel in an engine can do the same amount of work as about 50 people working for a whole day!

An average person can only produce about 0.9 horsepower of work. A small engine can produce much more. It takes a person more than an hour and a half of hard work to produce just one kilowatt-hour (kWh) of energy. A small engine can do that in less than an hour, using less than a liter of fuel. This shows why machines are so important for getting a lot of work done quickly and cheaply.

How Mechanization Grows

Mechanization can be seen as a series of steps, from very simple to very advanced:

- Step 1: Doing work only with your hands or muscles.

- Step 2: Using simple hand tools (like a hammer).

- Step 3: Using powered hand tools (like an electric drill).

- Step 4: Using powered tools that do one job over and over.

- Step 5: Using powered tools that can do many jobs and can be programmed.

- Step 6: Using powered tools that can be controlled from far away.

- Step 7: Machines that start working when something is put into them (like a coin phone).

- Step 8: Machines that can measure things.

- Step 9: Machines that can control other things (like a water power control).

- Step 10: Machines that record how well they are working.

- Step 11: Machines that change what they do based on measurements.

- Step 12: Machines that sort or reject things based on measurements.

- Step 13: Machines that choose the right action to take.

- Step 14: Machines that fix their own performance after they finish a job.

- Step 15: Machines that fix their own performance while they are working.

See also

In Spanish: Mecanización para niños

In Spanish: Mecanización para niños

| Sharif Bey |

| Hale Woodruff |

| Richmond Barthé |

| Purvis Young |