Paper machine facts for kids

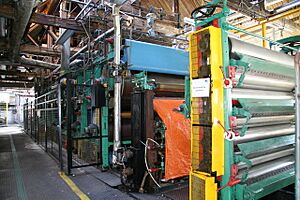

A paper machine is a huge industrial machine. It's used in paper factories to make lots of paper very quickly. Modern paper machines work like the original Fourdrinier Machine. This machine uses a moving screen to create a long, continuous sheet of paper. It works by taking out the water from a mix of fibers, leaving a wet mat of paper. This wet mat then gets dried to become strong paper.

This process is like a super-sized version of how paper used to be made by hand. But hand-making couldn't keep up with the world's need for paper! The first modern paper machine was invented in France in 1799 by Louis-Nicolas Robert. Later, Henry and Sealy Fourdrinier patented an improved version in Britain in 1806.

The same kind of process is also used to make paperboard, which is thicker than regular paper.

Contents

How a Paper Machine Works

Paper machines usually have several main parts that work together to turn a watery mix of fibers into dry paper. Let's explore them!

Making the Paper Sheet (Forming Section)

This part is often called the wet end. It has a continuous, rotating screen that looks like a giant conveyor belt. The watery mix of fibers (called stock) is poured onto this screen. As the screen moves, water is sucked out, leaving the fibers behind to form a wet sheet of paper.

The stock starts in a special box called the headbox. This box makes sure the fibers are spread out evenly and don't clump together. The watery mix then flows out of a narrow opening called the slice onto the moving screen, or wire. As the wire moves, water drains away, helped by special parts called foils and suction boxes. By the time the sheet leaves this section, it's about 25% dry.

Different Ways to Form Paper

- A secondary headbox can add another layer of fibers on top of the first. This is common for making linerboard, which is used for cardboard boxes.

- A top wire former adds a second screen on top of the main one. This helps drain water faster and makes the paper more even.

- A Twin Wire Machine uses two vertical screens. This helps remove water quickly and makes both sides of the paper look the same.

- Some machines have entire forming sections stacked on top of each other. These are called top Fourdriniers and they make multi-layer paper or paperboard. For example, they can make a white top layer over a brown, unbleached layer.

- The cylinder mould machine uses a rotating cylinder covered in mesh, partly dipped in the fiber mix. This creates a paper sheet with fibers spread out in a more random way. This can make paper thicker and stiffer, which is good for things like cereal boxes.

- Tissue machines are special. They form the paper between a screen and a special fabric. The wet paper then goes onto a huge heated cylinder called a yankee dryer. A blade scrapes the tissue off the dryer when it's ready. Tissue machines are super fast!

Squeezing Out Water (Press Section)

After the wet end, the paper sheet goes into the press section. Here, it passes between large rollers that squeeze out as much water as possible. These rollers are under very high pressure. Special thick fabrics called felts help support the paper and soak up the water. After this section, the paper is usually over 40% dry!

Types of Presses

- Conventional roll presses use smooth or grooved rollers. The paper goes through a "nip" (where two rollers meet) and water is squeezed into the felt.

- Extended Nip Presses (ENP) are newer. They have a special curved shoe that extends the time the paper is squeezed. This removes even more water, making the paper up to 45% dry or more. This saves a lot of energy in the next drying step!

Drying the Paper (Drying Section)

Next, the pressed paper sheet goes through the drying section. It winds around many large, heated cylinders that are filled with steam. These hot cylinders evaporate the remaining water. The paper usually ends up with about 6% water content, which is perfect for typical indoor conditions. Long felt loops hold the paper against the dryers to help it dry faster.

The drying sections are often enclosed to keep the heat in. Hot air is also blown into the spaces where the paper leaves the dryers to speed up drying.

Adding Special Coatings (Size Press)

Sometimes, the paper needs extra things added to it. This happens at the size press. Here, a thin layer of starch or other chemicals is applied to the semi-dried paper. This makes the paper stronger, smoother, and better for printing. It can also make it less likely to fuzz or absorb water too quickly. This section is usually placed before the very last drying cylinders.

Making it Smooth (Calender Section)

The calender section has two or more smooth rollers that press the dried paper. This makes the paper surface extra smooth and glossy. It also helps make the paper thickness very even. The more pressure applied, the smoother and glossier the paper becomes.

Winding it Up (Reel Section)

After being smoothed, the paper is wound onto large metal spools. This creates a giant roll of paper called a master roll. To keep the machine running non-stop, the reel can quickly switch from a full spool to an empty one without stopping the paper flow. This means the paper machine can run continuously!

Cutting the Rolls (Winder Section)

The master rolls from the reel section are very wide. In the winder section, these huge rolls are cut into smaller rolls of different widths and sizes, based on customer orders. Sharp cutting wheels slice the paper, and then the smaller rolls are wound up and labeled before being sent away.

History of Paper Machines

Before these amazing machines, paper was made one sheet at a time. People would dip a screen into a mix of pulp, lift it out, press the wet paper, and then hang it to air dry. This was a slow process!

The Fourdrinier Machine

In 1799, Louis-Nicolas Robert in France got a patent for a continuous paper-making machine. He worked with the Didot family, who thought England was a better place to develop the machine. So, Didot's brother-in-law, John Gamble, went to England. He met brothers Sealy and Henry Fourdrinier, who were stationers (people who sell paper and office supplies) in London. They decided to fund the project.

Gamble got a British patent in 1801. The Fourdrinier machine used a special woven fabric screen (called a wire) that moved like a conveyor belt. A watery mix of fibers (usually from wood) was put on this wire, and the water drained away, creating a continuous sheet of paper.

With help from a clever mechanic named Bryan Donkin, an improved version of Robert's machine was set up at Frogmore Paper Mill in England in 1803. More machines followed, and the process kept getting better.

Around the same time, in 1809, John Dickinson designed a different type of machine called a Cylinder Mould Machine. The first U.S. cylinder machine was made in 1817 by Thomas Gilpin. The Fourdrinier machine didn't arrive in the USA until 1827.

Other Early Designs

Records show that Charles Kinsey in New Jersey had already patented a continuous paper-making machine in 1807. His machine was making paper successfully by 1809! However, due to financial problems, his mill changed to making cotton, and his paper-making success was forgotten for a while.

Gilpin's 1817 patent and John Ames's 1822 patent were similar to Kinsey's. Ames's patent was even challenged because people thought he was using Kinsey's ideas!

Impact on Other Industries

The idea of continuous production shown by the paper machine was very important. It later influenced how other things were made, like the continuous rolling of iron and steel.

Making the Pulp

Paper is made from plant fibers, mostly cellulose. These fibers naturally stick together when water is present. When the water dries, they stay bonded, so you don't usually need to add extra glue for most paper types.

Long ago, paper was made from cotton and linen rags. Today, almost all paper pulp comes from wood. Cotton fibers are still used for special papers, like for resumes or money.

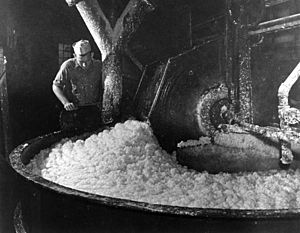

How Rags Become Pulp

Old rags, like denim scraps, can be used. These cotton fibers are cleaned with bleach and other chemicals, often using steam. Then, the cloth pieces are mechanically rubbed and cut into shorter fibers. This happens in a machine where the rags and water go into a loop. A spinning cylinder with cutting blades slowly lowers, breaking the rags into fibers and cutting them to the right length for paper making.

Another source of cotton fiber is from cotton ginning, which separates cotton fibers from seeds. The short fibers left on the seeds are called linters, and they are too short for fabric but good for paper.

Wood Pulp Types

The two main types of wood pulp are chemical and mechanical.

- Chemical pulps (like kraft pulp) dissolve the lignin (a natural glue in wood) that holds fibers together. This makes strong paper. Kraft pulp is great for things like cardboard and good quality printing paper.

- Mechanical pulps (like groundwood) are made by grinding wood. They contain a lot of lignin, which makes the paper weaker but cheaper. Newsprint and magazine paper often use groundwood.

- Thermomechanical pulp (TMP) is a type of groundwood where fibers are separated mechanically at high temperatures to soften the lignin.

- Semi-chemical pulps use a mild chemical treatment followed by grinding. These are often used for the wavy layer inside cardboard.

Recycled Paper

Recycled paper is also used. For brown packaging, it's simply cleaned and mixed with water. For white papers, it goes through a deinking plant to remove ink. Recycled pulp is used in printing paper, tissue, and paper towels, often mixed with new pulp.

At paper mills, pulp is stored in tall towers before being prepared for the machine. If a mill doesn't make its own pulp, it receives it in bales, which are then mixed with water in a machine called a repulper.

Preparing the Pulp for the Machine (Stock Preparation)

This is where the pulp gets ready to become paper. It's refined, mixed with different types of fibers (like hardwood, softwood, or recycled), and diluted to a very consistent thickness. The acidity (pH) is controlled, and things like whitening agents, size (to control how much water paper absorbs), and strength additives are mixed in.

Other things called fillers (like clay, calcium carbonate, or titanium dioxide) are added. These make the paper more opaque (so you can't see through it) and improve printing quality.

The pulp is pumped through a series of tanks called chests. These chests have stirrers to keep the fibers from clumping together, as fibers and fillers are heavier than water and can settle.

Refining the Fibers

From storage, the pulp is diluted and then pumped through a refiner. A refiner has two discs with raised bars, one spinning and one still. The pulp passes between them, which unravels the outer layers of the fibers. This increases their surface area, helping them bond better and making the paper stronger. For example, tissue paper is less refined, while packaging paper is more refined.

After refining, the pulp goes to a machine chest. This chest helps keep the pulp's thickness very steady before it goes to the paper machine.

Glossary

- broke: Waste paper made during the paper-making process, like from sheet breaks or trimmings. It's collected and recycled back into the process.

- consistency: The percentage of dry fiber in a watery pulp mix.

- couch: A French word meaning "to lie down." After the couch roll, the wet paper sheet is lifted off the screen and moved to the press section.

- dandy roll: A hollow roll covered in mesh that sits on top of the Fourdrinier screen. It breaks up fiber clumps to make the paper more even and can also create patterns like watermarks.

- fan pump: A large pump that moves the watery mix (white water) from a storage tank to the headbox. It's designed to pump smoothly to avoid making uneven paper.

- felt: A loop of fabric or synthetic material used in the press and dryer sections. In the press, it absorbs water and supports the paper. In the dryer, it holds the paper against the hot cylinders.

- filler: A fine substance added to paper during forming. Fillers make paper brighter, more opaque, and better for printing. Common fillers are clay and calcium carbonate.

- formation: How evenly the fibers are spread out in the finished paper. You can see it by holding paper up to the light.

- headbox: The chamber where the watery pulp mix is made turbulent to break up fiber clumps. Its main job is to spread the fibers evenly across the screen.

- nip: The area where two opposing rolls meet and press against each other, like in a press or calender.

- pH: A measure of how acidic or alkaline a solution is. Alkaline paper lasts a very long time, while acid paper can break down over time.

- size: A chemical or starch added to paper to slow down how fast it absorbs water. This helps ink stay sharp when printing.

- slice: The adjustable opening at the bottom of the headbox where the watery pulp mix flows out onto the screen. It controls the amount and speed of the flow.

- stock: The pulp mix that has been prepared with all the necessary additives and is ready to be made into paper.

- web: The continuous sheet of wet fibers moving along the paper machine before it's fully dried.

- white water: The water that drains from the forming section. It's usually collected and reused.

- wire: The woven mesh fabric loop used in the forming section to drain water from the pulp mix. It used to be made of bronze but is now made from strong synthetic materials.

Materials Used in Paper Machines

Stainless steel is used a lot in paper factories. This is mainly because it resists corrosion from the chemicals used in paper making and helps avoid iron getting into the paper product. Type 316 stainless steel is a common material for paper machines.

See also

- Paper chemicals

- Continuous production

- Cutting stock problem

| Precious Adams |

| Lauren Anderson |

| Janet Collins |