Reverse overshot water wheel facts for kids

The water wheel was a clever invention used by the Romans, especially in mines. They needed to get water out of the deepest parts of underground tunnels. The Romans came up with a special kind of water wheel called a reverse overshot wheel. It helped them lift water up, even from very low places.

This amazing machine was described by a Roman writer named Vitruvius around 25 BC. We know from old Roman mines that these wheels were often used together. They would work in a line, one after another, to lift water really high.

Contents

How Did Romans Remove Water from Mines?

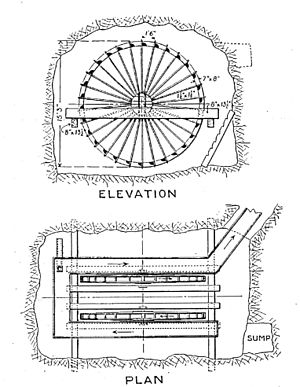

Vitruvius wrote detailed instructions on how to build machines that remove water. He described three types of a device called a "tympanum." This was a big wheel with boxes attached to it.

In the first design, the boxes went all the way around the wheel. When a box dipped into the water, it filled up. As the wheel turned, the box would lift the water. When it reached the top, the water would pour out into a channel.

Vitruvius also described a second type. Here, the boxes were only on the edges of the wheel. This meant it carried less water, but it could lift the water even higher. The third type was an endless chain of buckets. This could lift water much higher, but it needed more effort to operate.

What Did Pliny the Elder Say About Mine Workers?

Pliny the Elder, another Roman writer, probably talked about these water-lifting machines too. He wrote about silver and lead mines in his book Naturalis Historia. Spain was famous for its silver mines back then. Many of these mines were started by Hannibal.

Pliny described one huge mine with tunnels that went one or two miles into the mountain. He said "water-men" (called "aquatini" in Latin) worked day and night in shifts. They used lamps to see and kept bailing out water, making a constant stream. The fact that they "stood" suggests they operated the wheels by stepping on them to turn the parts. Working continuously would have kept the water flowing out of the mine.

Where Can We See Examples of Roman Water Wheels?

Parts of these ancient machines have been found in mines that were reopened much later, during the Victorian era. A great example comes from Rio Tinto in Spain. Here, archaeologists found parts of a system that used 16 water wheels!

These wheels worked in pairs. Each pair lifted water about 3.5 meters (11.5 feet). This means the whole system could lift water an amazing 30 meters (98 feet) in total! The system was very well-designed. People operated the wheels by stepping on slats at the side of each one.

Other examples have been found too. Oliver Davies, a historian, mentions wheels from the Tharsis copper mine and Logroño in Spain. He also found them in Dacia, which is modern-day Romania. The gold mines in Dacia were very rich after the Romans conquered the area. One system found in Ruda, Romania, was 75 meters (246 feet) deep. If it worked like the Rio Tinto example, it would have needed at least 32 wheels!

One wheel from Spain was saved and is now on display at the British Museum. Some parts of it are numbered, which suggests they were built above ground and then put together inside the mine tunnels. In the 1930s, a piece of a wooden bucket from a drainage wheel was found deep inside the Dolaucothi gold mine in west Wales. It's now in the National Museum of Wales in Cardiff. Scientists used carbon dating to find out it's about 90 AD. Since it was found 50 meters (164 feet) below other known workings, it was likely part of a series of wheels, just like in Spain. The shape of the bucket piece is almost exactly the same as those from Spain, which means they might have used a special pattern to make them.

What Was the Archimedean Screw?

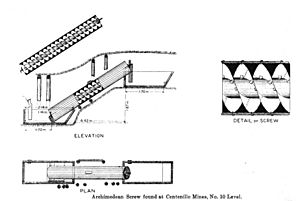

Another important device used by the Romans was the Archimedean screw, also called a "cochlea." Examples of these water-lifting machines have been found in many old mines. Pictures show that people would turn the screw by stepping on its outer casing.

These screws were also used in a series to lift water higher. However, they were probably harder to use because the person had to stand on a slanting surface to turn the screw. The steeper the angle, the more likely the person might slip. The reverse water wheel was probably easier to use because it had a flat surface to step on. The screw could also be turned with a crank handle on its central axle, but this would be more tiring because the operator's weight wouldn't help turn it.

Like the reverse water wheel, the Archimedean screw was used for many things besides draining mines. It was very popular for watering farms, but it could be used for any task that needed water to be lifted.

Other Uses of Roman Water Wheels

Romans used many water wheels in other parts of their empire too. A famous example is at Barbegal in southern France. This system also had 16 wheels stacked up, but they worked like normal overshot wheels. These wheels powered stone mills to grind grain. The water mills got their water from a stone aqueduct that supplied the Roman town of Arles. You can still see the remains of these mills today. Unlike the underground mine systems, which were often destroyed by later mining, these above-ground mills survived. Other similar groups of mills existed on the Janiculum hill in Rome, but they are now covered by newer buildings.

See also

- Mining in ancient Rome

- Roman engineering

- Roman technology

| Jackie Robinson |

| Jack Johnson |

| Althea Gibson |

| Arthur Ashe |

| Muhammad Ali |