Rotary kiln facts for kids

A rotary kiln is a special machine that heats materials to very high temperatures in a continuous process. Think of it like a giant, slowly spinning oven! It's used to make many important things that we use every day, such as:

- Cement (used in concrete for buildings and roads)

- Lime (used in agriculture, water treatment, and steelmaking)

- Refractories (materials that can withstand very high heat)

- Titanium dioxide (a white pigment used in paints and plastics)

- Alumina (used to make aluminum metal)

- Iron ore pellets (small balls of iron ore used in steel production)

Rotary kilns are also used to heat up different kinds of sulfide ores before metals like copper or zinc are taken out of them.

Contents

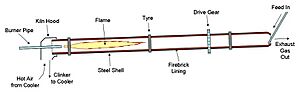

How a Rotary Kiln Works

A rotary kiln is a long, tube-shaped machine that is tilted slightly. It spins slowly around its middle. The material that needs to be heated, called the "feedstock," is put into the higher end of the tube. As the kiln spins, the material slowly moves down towards the lower end. This movement also helps to mix the material.

Hot gases flow through the kiln. Sometimes these gases move in the same direction as the material, but usually, they move in the opposite direction. These hot gases can come from a furnace outside the kiln, or they can be made by a flame inside the kiln itself. This flame comes from a special pipe, like a very big bunsen burner. The fuel for this flame can be gas, oil, or even powdered coal.

What a Rotary Kiln is Made Of

The main parts of a rotary kiln are its outer shell, the heat-resistant lining inside, the large support rings (called tyres) and rollers, the motor and gears that make it spin, and special parts inside that help transfer heat.

The Kiln Shell

The outer shell of the kiln is made from strong mild steel plates, usually about 15 to 30 millimeters (about ½ to 1⅜ inches) thick. These plates are welded together to form a long cylinder. This cylinder can be as long as 230 meters (754.5 feet) and up to 6 meters (19 feet 8 inches) wide!

There are limits to how wide a kiln can be because if it's too wide, it might start to bend into an oval shape from its own weight as it spins. Length isn't as much of a problem, but very long kilns need to be designed carefully to handle how much they expand and shrink when they get hot and cold.

Heat-Resistant Lining

Inside the steel shell, there's a special lining called a refractory lining. Its job is to protect the steel shell from the very high temperatures inside the kiln. It also protects the shell from the materials being processed, which can sometimes be corrosive. This lining can be made of special heat-resistant bricks or concrete.

The lining is usually between 80 and 300 millimeters (3.1 to 11⅜ inches) thick. A good lining can reduce the temperature by more than 1000°C (1,832°F) from the inside to the outside. The steel shell needs to stay below about 350°C (662°F) to prevent damage. Special infrared scanners are used to constantly check the shell's temperature and warn if there are any "hot-spots" that mean the lining might be failing.

Tyres and Rollers

The tyres, also called riding rings, are large, smooth steel rings that fit loosely around the kiln shell. They are designed to allow the kiln to expand and contract with heat. These tyres rest on pairs of smooth steel rollers. These rollers support the huge weight of the kiln and allow it to spin as smoothly as possible. A large kiln, like one that is 6 meters wide and 60 meters long (19 feet 8 inches by 196 feet), can weigh around 1100 tonnes (2.42 million pounds) with its lining and material inside! This weight is usually supported by three sets of tyres and rollers.

Kilns usually spin slowly, about 0.5 to 2 times per minute. Modern cement kilns can spin a bit faster, around 4 to 5 times per minute. Because the kiln is tilted, it also needs special "retaining rollers" to keep it from sliding off its support rollers.

Drive System

The kiln is usually turned by a large gear, called a Girth Gear, which goes around a cooler part of the kiln tube. This gear is connected to a powerful electric motor through a series of smaller gears. This motor needs to be very strong to start the heavy kiln spinning. A 6-meter by 60-meter kiln needs about 800 kilowatts of power to spin at 3 revolutions per minute.

The speed at which the material moves through the kiln depends on how fast the kiln spins. So, a variable-speed motor is needed to control this. It's dangerous for a hot kiln to stop spinning if the power goes out, because temperature differences could cause the kiln to bend or damage the lining. Because of this, most kilns have a backup drive system, like a small electric motor with its own power supply or a diesel engine. This backup system keeps the kiln spinning very slowly to prevent damage during power cuts.

Internal Heat Exchangers

Inside the kiln, heat can be transferred in different ways: by touching (conduction), by moving air (convection), and by heat waves (radiation). In parts of the kiln where temperatures are lower, or in very long kilns, special internal heat exchangers are often used to help transfer heat from the hot gases to the material.

These heat exchangers can be scoops or "lifters" that pick up the material and drop it through the hot gas stream. Or they can be metal parts that get hot in the upper part of the kiln and then transfer that heat to the material as they dip below its surface when the kiln rotates. The most common type of heat exchanger is made of chains that hang like curtains across the path of the hot gases.

Other Important Parts

The kiln has special seals at both ends to keep gases from leaking out. At the lower end, where the heated material comes out, there's a hood. At the upper end, where the waste gases leave, there are ducts. These exhaust gases might go straight out, or they might first go into a "preheater." A preheater is another device that uses the heat from the exhaust gases to warm up the incoming material, making the whole process more efficient.

A large fan at the exhaust end pulls the gases through the kiln and any preheaters. This fan can be very powerful, especially if there's a preheater that creates a lot of air resistance. The exhaust gases often contain dust and sometimes unwanted substances like sulfur dioxide. So, special equipment is installed to clean these substances from the gas stream before it is released into the atmosphere.

History of the Rotary Kiln

The idea for the rotary kiln came from Frederick Ransome in 1873. He tried to make it work commercially in the 1880s, but it wasn't a big success for him. However, his designs were very important and became the basis for successful kilns built in the United States starting in 1891. From there, the use of rotary kilns spread all over the world.

Images for kids

See also

- List of ovens

| Ernest Everett Just |

| Mary Jackson |

| Emmett Chappelle |

| Marie Maynard Daly |