South Crofty facts for kids

New Cooks Kitchen Shaft

|

|

| Location | |

|---|---|

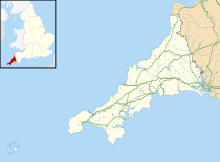

| Location | Pool |

| County | Cornwall |

| Country | United Kingdom |

| Coordinates | 50°13′22″N 5°16′29″W / 50.2227°N 5.2746°W |

| Production | |

| Products | Tin, copper |

| History | |

| Opened | 16th century |

| Closed | 1998 |

| Owner | |

| Company | Strongbow Exploration Inc |

South Crofty is a very old and important tin and copper mine. It is located in the village of Pool, in Cornwall, United Kingdom. People have been mining here for over 400 years!

The mine stretches almost two and a half miles wide. It also goes down about 3,000 feet (914 meters). Miners have dug out over 40 different lodes, which are veins of valuable minerals. Records show mining activity at South Crofty as far back as 1592. Full-scale mining really began in the mid-1600s.

The mine faced tough times after 1985 and finally closed in 1998. However, there are still plans to open it again with new owners.

Contents

The Story of South Crofty Mine

South Crofty Mine is a historic tin mine located in Pool. This area is between the towns of Camborne and Redruth. For many years, miners mostly dug for copper closer to the surface. They found tin deeper underground.

People were mining in this area as early as 1592. By the mid-1600s, mining was a big business here. Part of what is now South Crofty was once called Penhellick Vean.

Early Mining: The 1700s

Big changes happened in 1710. A man named Francis Bassett took over Penhellick Vean. He started digging a special tunnel called an adit to drain water from the mine.

Over the next 20 years, these shallow mines (less than 130 feet or 40 meters deep) produced a lot of valuable copper. This made the Bassett family very rich. But in the 1770s and 1780s, many new copper mines opened in Anglesey. This caused most mines around South Crofty to close down.

Growing Deeper: The 1800s

By 1822, a new mine called East Wheal Crofty was digging for copper. By 1833, it included Penhellick Vean. The mines were now much deeper, going down 260 feet (80 meters) or more.

In the 1830s, a lot of money was spent to make the mine better. They even built a rail link. By 1842, East Wheal Crofty was seen as a "model" mine. But this good time did not last. By 1863, part of the mine was for sale. The rest of the mine, now at least 690 feet (210 meters) deep, was renamed South Wheal Crofty. Later, "Wheal" was dropped, and it became South Crofty.

The mine changed a lot in the 1860s. South Wheal Crofty was mainly a copper mine. But by 1873, after investing in new machinery, the mine depended on tin for its money. Copper was still important until 1880, when all the easy-to-reach copper was gone.

The mine was now working at a depth of 260 fathoms (about 1,560 feet or 475 meters). Only tin was found at this depth. The price of tin then fell sharply. This hurt South Wheal Crofty directly by reducing its income. It also cost more to pump water as nearby mines closed. In February 1896, mining stopped, and the mine filled with water.

In 1899, the mine got new funding and slowly reopened. It also bought the nearby New Cooks Kitchen mine. Improvements were made, and the Robinsons Shaft began to be dug deeper in 1903. The mine started making money again. In 1906, a new company, South Crofty Limited, was formed.

Modernizing and Expanding: The 1900s

By 1908, the Robinsons Shaft reached 205 fathoms (about 1,230 feet or 375 meters) deep. Work also started on a second new shaft at New Cooks Kitchen. Miners began using more rock drills. By 1910, the mine was making a profit, bringing up 60,000 tons of ore each year. By 1914, the workings were down to 310 fathoms (about 1,860 feet or 567 meters).

For the next 70 years, South Crofty kept getting more modern and growing. As nearby mines closed, South Crofty bought them. This helped the mine get more ore from deeper areas. A big purchase was the Dolcoath mine in 1936.

Ore production increased to 92,000 tons in 1959. This was after improvements to the mine and the mill (where ore is processed). Production went over 100,000 tons for the first time in 1968.

The mine produced "black tin" (tin concentrate) steadily from 1907 to 1956. It also produced wolframite (a source of tungsten) and arsenic.

In 1967, South Crofty Ltd became part of a larger company. This led to a big project in 1969 to improve how ore was brought up and processed. By 1975, the mill was processing over 200,000 tonnes of ore each year. This produced about 1,500 tonnes of tin concentrate.

In 1982, the company was bought by Charter Consolidated. Then, in 1984, it became part of Carnon Consolidated Ltd.

In October 1985, the price of tin dropped very quickly around the world. This happened after an international agreement about tin collapsed. Carnon had to make changes. They closed the Pendarves mine, which had supplied ore to South Crofty's mill. With less ore, South Crofty's mill slowly shut down. By 1988, all South Crofty ore was taken by truck to be processed at Wheal Jane.

The number of workers was reduced. The mines were also made more efficient. A modernization plan, started before the tin price crash, was sped up. This was possible with help from the Department of Trade and Industry (DTI). They gave loans for improvements. Most of this money went to South Crofty.

In June 1988, Carnon became a private company. The employees even owned 20% of the company.

In February 1991, the DTI stopped supporting new projects. The company cut labor costs a lot. A small rise in tin prices helped the mine keep running, even with a small loss. These losses were covered by selling extra land and old equipment. In 1993, the mine produced about 1,900 tons of "black tin." This was sent to a smelter in Malaysia.

In 1994, a Canadian company bought South Crofty. At this time, it was thought the mine had enough tin to keep working for at least ten more years. The New Roskear shaft took over from the Robinson Shaft as the second main entrance.

However, tin prices stayed low for several more years. In August 1997, South Crofty Ltd announced it would close soon. After more attempts to keep it open, the mine finally closed in March 1998.

Hopes for Reopening: The 2000s and Beyond

In March 2001, a new local company bought the mine. Their goal was to reopen it. That same year, they started fixing up the New Cooks Kitchen part of the mine. By 2003, they were working underground to fix the Tuckingmill Decline and Old Engine shaft. Later that year, they dug a path to the New Cooks Kitchen Deep Adit level. The New Cooks Kitchen section was finished in October 2003. It even opened for public tours!

In 2004, mining started again at the 10 fathom (60 feet or 18 meters) level. They drilled a tunnel north from the Tuckingmill Decline to the New Cooks Kitchen Shaft. In 2006, they bought equipment from another closed mine, Wheal Jane. They planned to fix some of this equipment to use in a new processing mill at South Crofty.

Local people had mixed feelings about the mine reopening. Nearly 2,000 people came to an Open Day in support of the mine in July 2006. But others, like a local councilor and former miner, thought it was time to build new things on the site. A local company, CPR Regeneration, was against reopening the mine. They wanted to build a leisure center, then later housing and a business park. CPR tried to buy the South Crofty site by force in 2003, 2006, and 2007.

South Crofty said that delays in reopening were because Cornwall Council kept asking for reviews of their mining permits. After three reviews, the Council finally gave permission for the mine in September 2006. One month later, CPR Regeneration announced they would try to buy the site by force. They planned a huge development covering 150 acres (0.6 km2), including the South Crofty site. However, by March 2012, CPR Regeneration had stopped working.

In November 2007, a new company called Western United Mines Limited was formed to own and run the mine. The previous owner was a major shareholder. By this time, the mine employed 26 people. They expected to spend £9 million to reopen the mine by June 2008. They hoped to reopen fully by the end of 2009 after spending another £50 million. The owners said the mine could potentially operate for 80 years!

On November 28, 2007, the mine owners successfully challenged the development plan for the area. They argued that they had not been asked for their opinion.

The price of tin went up a lot, from under $4,000 per tonne in 2002 to over $17,000 per tonne in March 2010. This made the South Crofty mine much more likely to be successful. In 1994, it was estimated to have about 50,000 tonnes of tin.

In May 2011, a Canadian company, Celeste Copper Corporation, made a deal to take over the mine. By 2012, South Crofty covered the areas of about 34 old mines. Celeste Copper Corporation estimated there were about 7.95 million tonnes of tin in the mine. This was valued at £1.5 billion ($2.4 billion). The company planned to start pumping water out of the shallower parts in 2013.

However, in November 2012, UNESCO asked for work to stop. South Crofty is part of the Cornwall and West Devon Mining Landscape, which is a World Heritage Site. UNESCO said they were not asked before the mine got permission to reopen in 2011.

In June 2013, the South Crofty site went into administration, meaning it was managed by others due to financial problems.

In October 2015, a local newspaper again suggested the mine could reopen. In March 2016, another Canadian company, Strongbow Exploration, bought South Crofty.

In April 2017, Strongbow announced a report about the mine's economic potential. In October 2017, Strongbow got a permit to pump treated water into the Red River. This means South Crofty can now work towards making a decision about starting production. By early 2018, they had money to build a water treatment plant. Test drilling began in June 2020.

| Victor J. Glover |

| Yvonne Cagle |

| Jeanette Epps |

| Bernard A. Harris Jr. |