Steam spring facts for kids

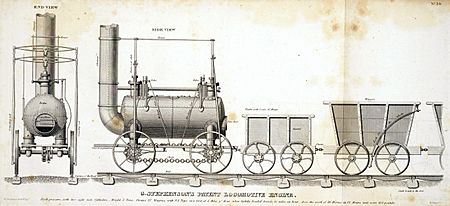

Imagine a bouncy part on a train that helps it ride smoothly. Early steam trains sometimes used something called steam springs or steam suspension. These were special parts that helped the train absorb bumps. They were invented by George Stephenson, a famous engineer. However, they were only used for a short time and on a few trains.

Contents

Why Trains Needed Springs

Early railway tracks were made of cast-iron. These tracks were quite brittle, meaning they could easily crack. This was a problem when heavy steam locomotives started to appear in the 1820s. These new trains were much heavier than the old horse-drawn wagons.

Also, early locomotives had their main engine parts (called cylinders) placed upright inside the boiler. When the engine's pistons moved up and down, they created a strong downward force. This force, called "hammer blow," put even more stress on the tracks.

Another reason for springs was to help the train wheels grip the rails better. To pull a train, the wheels need good contact with the track. If the track was bumpy, the wheels might lose their grip. Many people at the time wondered if a smooth iron wheel could grip the rail enough to pull a train. Some inventors thought trains would need special geared teeth on their wheels. But George Stephenson believed that if the wheels could stay in good contact with the rails, friction alone would be enough to move the train.

How Steam Springs Worked

When these early locomotives were built, it was hard to make strong metal springs. The special steel needed for good springs was very expensive. It would be many years before new ways of making steel cheaply were invented. Because of this, Stephenson had to find a different way to make his trains bouncy.

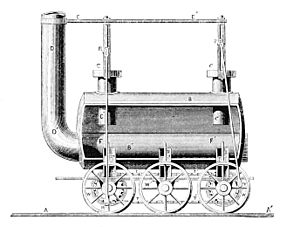

Stephenson's "steam suspension" gave each wheel its own "steam spring." Small cylinders were built into the bottom of the boiler, right above each axle. Inside each cylinder, a piston pushed upwards against the steam pressure from the boiler. This steam pressure helped support the weight of the train. Even a small piston, just a few inches wide, was enough to balance the locomotive's weight. The parts that held the axles (called axleboxes) could slide up and down. This allowed the wheels to move with the bumps in the track.

Keeping the pistons sealed was a big challenge back then. As steam engines became more powerful, the seals had to be stronger. Even though the steam spring cylinders were low in the boiler, they often leaked steam. Because of these problems, the steam springs were eventually removed. They were replaced with metal leaf springs, which are like flat layers of metal stacked together.

Early Killingworth Locomotives

George Stephenson's first locomotive was called the Blücher in 1814. It had four wheels connected by gears. This train had trouble gripping the new "edge rails" (tracks with a raised edge for the wheel flanges). This was thought to be because the wheels couldn't maintain good contact. The Blücher was the first of a group of early trains known as the "Killingworth Colliery locomotives." Stephenson's next design was similar but used a chain drive to connect the wheels. This was his first train to use steam springs.

The Duke Locomotive

Stephenson became known for building locomotives. He was asked to build the first train for Scotland, for the Kilmarnock and Troon Railway. This train was named The Duke. It was larger, with six wheels, and used the same chain drive and steam springs as the Killingworth trains.

The Duke was likely finished in 1817. It ran in Kilmarnock but seemed to continue having problems with breaking the rails. It was later sold in 1824 and used as a stationary engine, meaning it stayed in one place to power pumps. Its final fate is not known.

Hetton Colliery Locomotives

Five locomotives were built for the Hetton Colliery between 1820 and 1822. Four of them had names: Hettton, Dart, Tallyho, and Star. These trains were similar to The Duke but had four wheels. They were built with steam springs, but these were later removed because of steam leakage problems.

In 1852, a train called Lyon was built as a copy of these early Hetton locomotives.

Later Locomotives and Locomotion

Later locomotives stopped using steam springs. For the famous Locomotion on the Stockton and Darlington Railway in 1825, there were no springs at all. However, it had a special feature to help its wheels stay on uneven tracks. One of the axles was held in a "cannon box" bearing that could tilt from side to side. This allowed the wheels to follow the track's bumps.

Because of this "cannon box" between the wheels, Stephenson could no longer use the central chain drive. So, for the first time, he used coupling rods, which are now common on many trains. These rods connect the wheels on the outside.

The lack of springs on Locomotion caused its original cast-iron wheels to break. They were replaced with stronger, two-piece cast-iron disc wheels. By this time, stronger wrought iron rails were also being used, which helped reduce track breakage.