Belper North Mill facts for kids

The mill in 2006

|

|

| Cotton | |

|---|---|

| Structural system | Industrialised iron framed 'fire-proof' brick |

| Location | Belper, Derbyshire, England |

| Client | William Strutt |

| Coordinates | 53°01′42″N 1°29′13″W / 53.0282°N 1.4869°W |

| Construction | |

| Built | 1804 |

| Floor count | 6 |

| Floor area | 127 feet (39 m) long by 31 feet (9.4 m) wide |

| Floor usage | In 1804

|

| Design team | |

| Awards and prizes and listings | World Heritage Site |

| Water Power | |

| Wheels | 1 |

| Diameter / width of water wheel | 18 feet (5.5 m) / 23 feet (7.0 m) |

| Carding Equipment | 136 |

| Ring Frames path | 80 spinning frames with 4236 spindles |

| Other Equipment | 1812

|

Belper North Mill, also known as Strutt's North Mill, is a very important historic building in Belper, England. It's part of the Derwent Valley Mills, which became a World Heritage Site in 2001. This means it's recognized globally for its special history and importance.

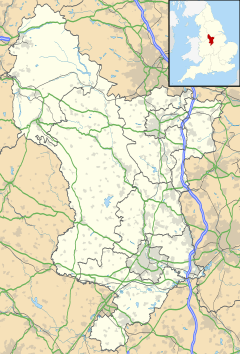

The mill is located in Belper, a town in Derbyshire. It sits about halfway between the cities of Derby and Matlock.

The first North Mill was built in 1786 by Jedediah Strutt. Sadly, it was destroyed by a fire in 1803. His son, William Strutt, quickly rebuilt it in 1804. This new mill was special because it was one of the first buildings ever made with an iron frame to be "fire-proof."

In 2015, a report mentioned that the North Mill needed repairs because it had some damage.

Contents

Belper North Mill: A Historic Cotton Factory

What is Belper North Mill?

Belper North Mill was once a busy factory where cotton was spun into thread. It's famous for being one of the earliest buildings to use an iron frame. This design helped prevent fires, which were a big problem in old cotton mills.

The mill is a key part of the Derwent Valley Mills. This area is known as the birthplace of the factory system. It changed how things were made and how people worked.

How Was the Mill Built to Be Fireproof?

Cotton mills faced a big danger: fire. Cotton dust catches fire very easily. When a fire started, it would quickly burn through wooden floors and ceilings. The first North Mill burned down this way.

To stop this from happening again, William Strutt tried something new. He used cast iron beams instead of wood to support the floors. Between these iron beams, he built low arches made of brick. Rubble was then used to level the floor, which was also made of brick.

Strong Iron Bones

The iron beams were shaped like a "turtle back" to make them strong but not too heavy. They rested on cast iron columns stacked on top of each other. Hidden wrought iron ties connected the tops of the columns. These ties helped hold the brick arches in place.

This building was one of the very first to use an iron frame. It was a huge step forward in building design. This technology later led to the steel frames used in today's tall skyscrapers. The roof was made of slate and had special gutters inside.

The mill is about 127 feet (39 m) long, 31 feet (9.4 m) wide, and 63 feet (19 m) high. It also had two wings, each about 41.5 by 34 feet (12.6 by 10.4 m).

How Did the Waterwheel Power the Mill?

The mill was powered by a large waterwheel built by Thomas Hewes. This waterwheel was 18 feet (5.5 m) tall and 23 feet (7.0 m) wide. It was a special type called a "suspension wheel," which made it lighter.

The power from the waterwheel was taken from its edge by a gear. This power then traveled up a vertical shaft. From this main shaft, gears connected to horizontal shafts on each floor. Leather belts then linked these shafts to all the individual machines.

What Happened on Each Floor?

Each of the mill's five main floors had a different job in turning raw cotton into thread.

From Raw Cotton to Thread

- Ground Floor: Raw cotton bales arrived here on carts. Machines opened and cleaned the cotton. They prepared it into a flat, fluffy layer called 'lap.'

- Third and Fourth Floors: The 'lap' was taken to these floors, which had over 130 carding engines. Carding machines untangled the cotton fibers. They turned them into a long, continuous rope of fibers called a 'sliver.'

- Drawing Frames: Sixteen drawing frames then straightened the fibers even more. They pulled the 'slivers' into thinner 'rovings' and added a slight twist. These 'rovings' were coiled into large cans, ready for spinning.

- First and Second Floors: These floors originally held 34 Arkwright water frames. These machines could spin 4,236 threads at once! They twisted the 'rovings' into strong threads, which were collected on small bobbins. Later, mule spinning machines were added to make even finer threads.

- Fifth Floor: The bobbins of spun thread came here. Reeling frames wound the thread into 'skeins' for dyeing. Doubling frames twisted two or more threads together to make them thicker and stronger. The amount of twist changed how the thread would be used.

- Attic: Later, the attic space was used as a schoolroom for children.

What Machines Were Used?

The mill was filled with many machines to process cotton. Here are some of them:

- 80 spinning frames with 4,236 spindles (parts that hold and twist thread)

- 136 carding engines (for untangling cotton fibers)

- 16 draw frames (for straightening fibers)

- 4 stretching frames

- Plus reeling, doubling, and twisting frames (for finishing the thread)

Green Power Today: Hydro-electric Plant

In 1998, a modern hydro-electric power generator was installed at the mill. This system uses the power of water, just like the old waterwheel, to create electricity. It produces 350 kilowatts of power using two water turbines. This shows how the mill continues to use renewable energy even today!

See also

- Grade I listed buildings in Derbyshire

- Listed buildings in Belper