Cartridge (firearms) facts for kids

A cartridge, also known as a round, is like a small package for a firearm. It holds everything needed to fire: the bullet, the gunpowder, and a small part called the primer. All these parts are put together in a metal case. This case is made to fit perfectly inside the gun's firing chamber.

The primer is a tiny bit of chemical that reacts when hit. It can be in the middle of the cartridge's base (called centerfire ammunition) or around the edge (called rimfire ammunition). Some cartridges have even been made to fire with electricity! There are also "caseless" cartridges that don't have a metal case.

If a cartridge doesn't have a bullet, it's called a blank. A cartridge that can't be fired at all is called a dummy.

It's important to know that people often use the word "bullet" to mean the whole cartridge. But this is not correct! A "bullet" is only the part that flies out of the gun. The whole thing is called a cartridge or a round.

How Cartridges Work

The cartridge case helps seal the firing chamber inside the gun. This seal stops gas from escaping in the wrong direction. When a gun's firing pin hits the primer, it lights up. This spark then ignites the gunpowder inside the case.

The burning powder creates a lot of hot gas. This gas pushes the bullet out of the barrel of the gun. After the bullet leaves, the pressure drops. This allows the empty cartridge case to be removed from the gun.

Modern guns, like automatic and semi-automatic ones, remove the empty case automatically. Sometimes, this process can slightly damage the case.

Most cartridge cases are made from Brass. Brass is good because it doesn't rust easily. It's also flexible enough to be reused and refilled many times. However, some cheaper ammunition, especially for target practice, uses steel cases. Some military ammunition also uses steel because it costs less than brass. Steel cases are not as flexible as brass. But for military use, cartridges are usually thrown away after one shot. Some cartridges are also made with aluminum cases.

Cartridge Features

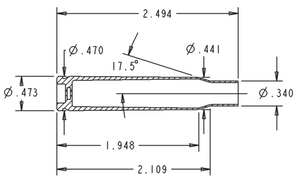

Cartridges have important features that make them work correctly. These include the caliber (the bullet's diameter), the bullet's weight, and how fast it's expected to go. Other features are the maximum pressure it can handle and the type of primer. Even small differences in these features can damage a gun. In serious cases, it could even hurt the person using the gun.

The diameter of a bullet is measured in inches (like .22 or .308) or in millimeters (like 9mm). The length of the cartridge case can also be measured in millimeters.

Most powerful guns use smaller bullets that travel very fast. This is because a bullet's energy increases much more with speed than with weight. So, a bullet going twice as fast has four times the energy! The speed of bullets is limited by how strong the gun materials are and how much weight a person can carry. Bigger cartridges usually have more powder and can make bullets go faster.

Today, there are mainly two types of cartridge designs: rimfire and centerfire. The US military is also working on "electronic firing" systems. These systems use an electric charge to ignite the primer instead of a firing pin.

History of Cartridges

The first military cartridge was made in 1586. It was a paper tube holding powder and a bullet. This is why thick paper is still sometimes called cartridge paper.

Soldiers used these early cartridges with muzzle-loading guns. They would tear or bite off the end of the paper tube. Then, they poured the powder into the gun barrel. The bullet was then pushed down the barrel.

Before the flintlock gun was invented around 1635, soldiers used a special fine powder to prime their guns. They put this powder into a small pan on the gun.

As fighting changed, soldiers needed guns that could fire faster. This led to the flintlock musket. With this gun, a small piece of powder from the cartridge was put into the pan to prime it. Then, the rest of the cartridge was pushed down the barrel.

Later, new inventions made this priming step unnecessary. Some powder from the main charge would automatically go into the pan when loading.

A big step forward was the copper percussion cap. This was first used widely by the British military in 1842. This was about 25 years after the idea of percussion powder was invented. The invention that made the percussion cap possible was patented in 1807. It used a special powder that exploded when hit. This idea slowly developed, first using steel caps, then copper caps. It took almost 30 years for it to be used by armies everywhere.

Images for kids

-

From left: A .577 Snider cartridge (1867), a .577/450 Martini-Henry cartridge (1871), a later brass .577/450 Martini–Henry cartridge, and a .303 British Mk VII SAA Ball cartridge.

-

The 8 mm Lebel ammunition, made in 1886. It was the first smokeless gunpowder cartridge used by a country.

-

An example of caseless ammunition, used in the Heckler & Koch G11 rifle.

See also

In Spanish: Cartucho (armas de fuego) para niños

In Spanish: Cartucho (armas de fuego) para niños