Leaf spring facts for kids

A leaf spring is a simple type of spring. It helps vehicles like cars and trucks move smoothly. People first called them laminated or carriage springs. They are one of the oldest spring types. They appeared on carriages in England after 1750. Then they spread to France and Germany.

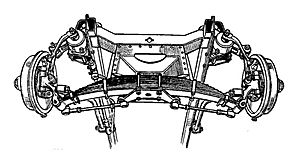

A leaf spring looks like a long, thin arc. It's made from strong spring steel. It has a rectangular shape. Usually, the middle of the arc connects to the vehicle's axle. Loops at each end attach to the vehicle's frame. For very heavy vehicles, many leaves are stacked. These leaves are often shorter at the top.

Leaf springs help hold the axle in place. They also help absorb bumps. The rubbing between the leaves can help dampen movement. But this damping is not always smooth. Because of this, some vehicles use single-leaf springs.

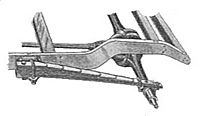

A leaf spring can connect to the frame in two ways. It can attach directly at both ends. Or, one end (usually the front) attaches directly. The other end connects through a shackle. A shackle is a short, swinging arm. It lets the spring get longer when it's pressed down. This makes the ride softer. Some older springs had a special concave end. This was called a spoon end. It held a swiveling part.

Modern cars like the Volvo XC90 (from 2016) use a new type of leaf spring. It's a straight leaf spring made of strong composite materials. This is similar to the Chevrolet Corvette. This spring is secured to the chassis. Its ends bolt to the wheel suspension. This allows each wheel to move independently. This design makes the suspension smaller, flatter, and lighter.

Contents

History of Leaf Springs

There have been many types of leaf springs. They often used the word "elliptical."

Different Types of Leaf Springs

- Elliptical springs: These looked like two circular arcs joined at their ends. The top center connected to the frame. The bottom center connected to the axle.

- Semi-elliptical springs: These used only the lower arc. They are common in systems like the Hotchkiss drive.

- Quarter-elliptic springs: These often had the thickest part stuck into the vehicle's frame. The free end attached to the axle. An example is the Austin 7 car from the 1920s.

- Yoke-shaped springs: The Ford Model T used multiple leaf springs. They were curved like a yoke over the differential.

To help absorb bumps, some car makers put non-metal sheets between the metal leaves. Wood was sometimes used for this.

| Elliptic |  |

| Semi-elliptic |  |

| Three quarter-elliptic |  |

| Quarter-elliptic |  |

| Transverse |  |

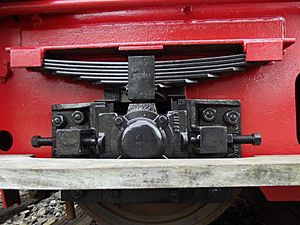

Leaf springs were very common on automobiles until the 1970s. Then, car makers started using coil springs more often. This was due to new front-wheel drive designs. Today, leaf springs are still used in heavy vehicles. These include vans, trucks, SUVs, and railway carriages.

Why Leaf Springs Are Still Used

For heavy vehicles, leaf springs spread the load widely. Coil springs put the load on a single point. Unlike coil springs, leaf springs also hold the rear axle in place. This means other parts like trailing arms are not needed. This saves money and weight. Another benefit is that the end of a leaf spring can be guided.

Parabolic Leaf Springs

A newer type is the parabolic leaf spring. This design uses fewer leaves. The leaves are thicker in the middle and thinner at the ends. This shape follows a parabolic curve. In this design, the leaves only touch at the ends and in the center. Spacers keep them from touching elsewhere. This design saves weight. It also offers a smoother ride. The ride quality is closer to that of coil springs. However, they cannot carry as much weight. Parabolic springs are widely used on buses for better comfort.

British company GKN and Chevrolet (with the Corvette) developed composite plastic leaf springs. These springs are very light. But they need stronger shock absorbers. This is because they don't have the natural damping from inter-leaf friction.

When used in cars, leaf springs support the axle. They also help position it. But this can cause handling problems. The spring's flexibility makes it hard to control the axle precisely. Some car designs use other parts like a Watts link. These parts help position the axle. This allows for softer springs and a better ride. Examples include the Austin-Healey 3000 and Fiat 128 rear suspensions.

Images for kids

See also

In Spanish: Suspensión de ballesta para niños

In Spanish: Suspensión de ballesta para niños

| Selma Burke |

| Pauline Powell Burns |

| Frederick J. Brown |

| Robert Blackburn |