Mechanicville Hydroelectric Plant facts for kids

Quick facts for kids |

|

|

Mechanicville Hydroelectric Plant

|

|

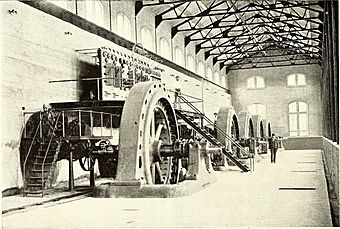

Powerhouse of Mechanicville Hydroelectric Plant in 1898.

|

|

| Nearest city | Mechanicville, New York |

|---|---|

| Area | 18.3 acres (7.4 ha) |

| Built | 1897 |

| Architect | Rice, A.C.; Stillwell-Bierce & Smith-Vaile |

| Architectural style | Queen Anne |

| NRHP reference No. | 89001942 |

| Added to NRHP | November 13, 1989 |

The Mechanicville Hydroelectric Plant is a special place in Mechanicville, New York. It's a 18.3-acre (7.4 ha) historic area in Saratoga County, New York. This plant was built way back in 1897 and shows off the beautiful Queen Anne design.

This historic site includes the main power building, a large earth wall, and a concrete dam. There's also a long concrete dam that stretches 700 feet (210 m) across the Hudson River. These structures were built in 1897–1898 by the Hudson River Power Transmission Company. They sit between the Saratoga County shore and Bluff Island.

The plant was added to the National Register of Historic Places in 1989. It was designed to make 5000 kilowatts of electricity using seven special machines called turbine-generators. Since 2003, after lots of updates, the plant has become a working museum. This means you can see how it still makes power today!

Contents

Building the Power Plant

Robert Newton King, who was the head of a company called Stillwell-Bierce & Smith-Vaile, chose this spot. He picked it because the Hudson River here had great potential to make electricity. It was also close to big industrial cities like Albany, Troy, and Schenectady.

The Hudson River Power Transmission Company was created to build this project. The Hudson River gets its water from the Adirondack Mountains. Construction started in July 1897. A big storm in November caused some delays. But by May 1898, the first generator was tested. Power was sent to the General Electric factory in July 1898. The first five turbines were ready by August 1898.

How the Turbines Work

The plant first used seven special turbines called Francis-type turbines. These were made by King's company. Each turbine had four spinning parts, about 41 inches (104 cm) wide. They could produce 1000 horsepower (HP) each.

These turbines spun generators that made 12,000 volts of electricity. This power was sent out at 38 cycles per second (Hz). Later, in 1902, all seven turbines were replaced with newer, more powerful ones. These new turbines could make 1250 HP. The plant's operating speed was also increased to 40 Hz.

For a short time, a steam engine was added to help make power when the river water was low. This engine was used for only five years. Today, six of the original seven turbines are still working.

The Plant's Buildings and Dams

The Mechanicville Hydroelectric Plant has a long spillway that is 900 feet (270 m) long. It also has an earth dam that is about 900 feet (270 m) long and 20 feet (6.1 m) high. The main power building, called the powerhouse, is 220 feet (67 m) wide and 50 feet (15 m) long. It is made of strong concrete.

Inside the powerhouse, the turbines are placed horizontally. Their shafts go through a thick concrete wall, which is 6-foot (1.8 m) thick. This special way of arranging the turbines and generators was new at the time. The design of this station became a model for many other power plants built later.

Sending Out Electricity

Most of the electricity made at Mechanicville was sent to the General Electric factory in Schenectady. Some of the 40 Hz power was used locally for lights and motors until 1949.

In 1899, the Hudson River Power Company took over the plant. They started running it alongside a newer, bigger plant called Spier Falls. At first, people had to manually control the speed of the Mechanicville units. But in 1902, automatic systems were installed.

From 1935 until the end of World War II, a special system called HVDC Mechanicville–Schenectady sent power to the GE plant. This system also changed the electricity from 40 Hz to 60 Hz.

The first electrical switches used in 1897 were open and operated with long wooden sticks. This was quite dangerous! In 1902, safer, oil-enclosed switches were installed. Then, in 1920, the system was updated again with remotely controlled circuit breakers. The control board from 1920 is still there today.

In 1949, new machines were added to change the plant's power to the standard 60 Hz. This allowed the plant to provide power to regular electricity networks.

Becoming a Working Museum

In the 1960s, the Niagara Mohawk Power Company, which owned many old hydroelectric plants, started tearing down smaller ones. They wanted to focus on bigger power stations. Niagara Mohawk owned the Mechanicville plant and planned to demolish it too.

However, by 1985, there was a new plan to use the water power at the site. This encouraged them to keep the plant. In 1993, the plant got a new 50-year license to keep operating. But in 1997, the company shut it down. They thought the power from a renovated plant wouldn't be cheap enough compared to other sources.

The plant stayed closed until 2003. After some legal discussions, the Albany Engineering Company took ownership. They started making electricity again! They did many repairs and updates to modernize the plant. The plan is to make the outside look like it did in 1898, while still producing power. In 2005, Albany Engineering even got permission to study adding another, underground generator unit.

Images for kids

| George Robert Carruthers |

| Patricia Bath |

| Jan Ernst Matzeliger |

| Alexander Miles |