Royal Ironworks of St John, Ipanema facts for kids

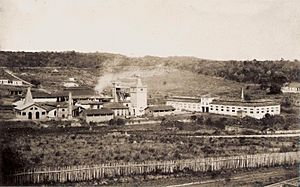

The Royal Ironworks of St John, Ipanema (Portuguese: Real Fábrica de Ferro São João do Ipanema), also known as Fundição Ipanema, was the very first ironworks in Brazil that worked continuously for a long time. An ironworks is like a big factory where iron is made. It is located near the city of Iperó, in the state of São Paulo. Today, you can still see the well-preserved ruins of its two large furnaces. Nearby, there is a small community called Fazenda Ipanema.

Contents

History of Iron Making

Early Days of Iron

This important factory was carefully planned by the Portuguese Crown, which was like the government of Portugal at the time. It operated from 1810 to 1821. After Brazil became independent, the Brazilian Imperial government continued to run it from 1822 to 1889. It closed for a while, then reopened in 1917 during the First World War, and finally closed in 1926. Over its years of operation, it produced thousands of tons of cast iron using its two big furnaces.

People knew about the magnetic iron ore on Araçoiaba Hill as early as 1590. Two men named Afonso Sardinha (father and son) set up a simple furnace there. This might have been the first time iron was made in America! This early iron-making spot might have worked for about twenty years.

Before 1808, when the Portuguese royal family moved to Brazil, making iron in the colony was usually not allowed. Only at certain times and places could people make iron.

New Ideas for Ironworks

After some big changes at the University of Coimbra in Portugal, many students were encouraged to study minerals and how to make metals. The Portuguese government sent some of these students to travel around Europe. For example, Jose Bonifacio de Andrada e Silva and Manuel Ferreira da Camara traveled for eight years, learning about iron-making in different countries.

When the Portuguese royal family arrived in Brazil in 1808, they invited some German experts, like Frederico Luiz Varnhagen, to help set up new iron factories in Brazil.

The Royal Ironworks of St John

D. Rodrigo de Souza Coutinho, a minister to the king, asked Varnhagen to design a modern factory to use the iron ore from Araçoiaba. Their plan was ready in July 1810. It also mentioned that they needed to bring in experts from Europe who knew a lot about making iron.

The factory officially started on December 4, 1810. It was a company where both the Portuguese Crown and private investors owned parts of it. The Crown owned 13 shares, and private people from São Paulo, Rio de Janeiro, and Bahia owned 47 shares.

The location for the factory was chosen carefully. It needed a lot of wood to fuel the furnaces and plenty of water to power the machines that blew air into the furnaces and operated the hammers. It also had to be close to the iron ore deposits. So, the factory was built near the Ipanema Hill and a dam was built on the Ipanema River to provide water.

A team of Swedish experts, led by Carl Gustav Hedberg, was hired in 1809. They brought books, tools, and equipment. However, they didn't build the large furnaces right away. Instead, they built four smaller ones. Later, a much bigger building was constructed on that site. In 1815, Hedberg was replaced by the German expert Friedrich Ludwig Wilhelm Varnhagen. Varnhagen was specifically asked to build the large furnaces for the factory. A Swedish foreman, Lars Hultgren, stayed and helped Varnhagen a lot with building and running the furnace.

Varnhagen had come to Portugal in 1803 to manage another ironworks. He then traveled to Brazil in 1809, following the royal family. The Royal Ironworks of St John was one of the important projects that happened because the royal family moved to Brazil. Varnhagen was very successful. He showed that the Ipanema ironworks could make a lot of iron and be profitable. This factory was the first in Brazil to produce iron using a more advanced method, making "pig iron." For some time, it produced about one and a half tons of iron every day. It made many useful things like iron plates for kitchen stoves, pans, ammunition, war materials, wire, spades, nails, axes, and sickles.

When the Portuguese king D. João VI decided to return to Portugal in 1821, Varnhagen went with him.

Later, the Brazilian army became very interested in the national iron industry. They wanted Brazil to be able to make its own iron.

Under the guidance of Johann Bloem, the furnaces at the Real Fábrica de Ferro de Ipanema produced guns and ammunition. It also made many items needed in Brazil during the 1800s, such as pans, iron rollers for sugar mills, iron railings, bars, ladders, and lanterns. Some of these items even won awards at national and international fairs!

The Ironworks received support from the Brazilian Imperial Government again from 1865 to 1889, led by Joaquim de Souza Mursa. During this time, a 4-kilometer railroad was built to connect the mine to the factory. The old furnaces were rebuilt to make more iron. A new unit was added to refine iron using technology from Austria. A rolling mill was also installed. They even hired a mining engineer to help run the factory. There were plans to add an even bigger furnace and a new system to produce liquid steel, but the factory stopped operating in 1895 because it wasn't making enough money.

The Real Fábrica de Ferro de Ipanema is considered the starting point of Brazil's steel industry. Less than 20% of its original buildings remain today. Its two large furnaces still stand and are protected by ICMBio, an environmental agency, within the National Forest of Ipanema, in Iperó.

Official documents about the factory are kept in archives and can be viewed by the public at places like the National Archives and the National Library of Brazil.

See also

- Ipanema Hill

- Francisco Adolfo de Varnhagen

- Sorocaba

- Iperó

- list of preserved historic blast furnaces

| James Van Der Zee |

| Alma Thomas |

| Ellis Wilson |

| Margaret Taylor-Burroughs |