Spinning mule facts for kids

The spinning mule is a special machine. It was used to make yarn from cotton and other fibers. These machines were very important from the late 1700s to the early 1900s. They were common in factories in places like Lancashire, England.

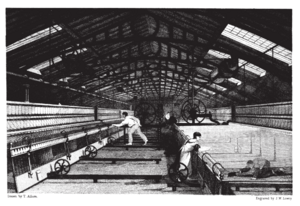

A spinning mule could be very long, sometimes up to 45 meters! It had many spindles, sometimes over a thousand. These spindles moved back and forth, spinning the fibers into strong yarn. Workers, often with the help of young assistants, operated these machines.

Samuel Crompton invented the spinning mule between 1775 and 1779. Later, Richard Roberts made an automatic version in 1825. At one point, there were millions of mule spindles in Lancashire alone! Even today, modern spinning mules are used. They spin fine woollen yarns from special fibers like cashmere and alpaca.

The spinning mule works in steps. First, it pulls and twists the fibers. Then, it winds the newly made yarn onto the spindle. This was different from other machines that spun yarn in one continuous motion. The spinning mule was the most popular spinning machine for over a century. It was even used for very fine yarns until the 1980s.

Contents

The Amazing Spinning Mule

How the Spinning Mule Changed Things

Before the 1770s, most cloth was made at home. Families worked together to make flax and wool textiles. Children and women would prepare the fibers. Women would then spin these fibers into yarn using a spinning wheel. Men would weave the yarn into cloth on a loom.

Early Ways of Making Cloth

An invention called the flying shuttle by John Kay made weaving much faster. This meant weavers needed a lot more yarn than spinners could make. People started looking for new ways to spin yarn faster.

There were two main types of spinning wheels. One used an "intermittent" process, spinning in steps. The other, a more advanced Saxony wheel, spun continuously. These wheels gave inventors ideas for new machines. Businessmen like Richard Arkwright supported inventors to create better spinning methods.

New Ideas for Spinning

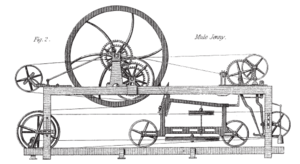

The spinning jenny was one new invention. It could spin eight threads at once. It worked by clamping fibers, stretching them, and then twisting them into yarn. The spinning jenny was easy to use by hand. However, it made weaker thread, only good for the "weft" (the side-to-side threads in cloth).

Another machine, the water frame, used rollers to pull and twist fibers. It made strong thread, good for the "warp" (the strong threads stretched on a loom). But it needed a lot of power, usually from a water wheel. The spinning mule combined the best ideas from these two machines.

Samuel Crompton's Clever Invention

Samuel Crompton invented the spinning mule in 1779. It was called a "mule" because it combined features from the water frame and the spinning jenny. Just like a mule is a mix of a horse and a donkey!

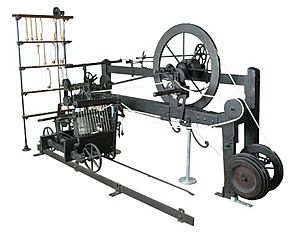

Crompton's mule had a fixed frame that held the raw fibers. A moving part, called a carriage, held the spindles. As the carriage moved out, the fibers were pulled, stretched, and twisted. When it moved back, the new yarn was wound onto the spindles.

Crompton built his first mule mostly from wood. It had 48 spindles and could make about half a kilogram of fine thread each day. This machine made strong, thin yarn suitable for any type of cloth. It was first used for cotton, then for other fibers. Crompton couldn't afford to patent his invention, so others later improved upon it.

Making Mules Automatic

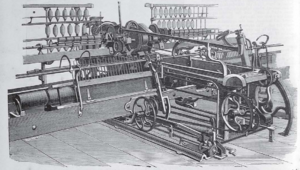

Over time, many improvements were made to the spinning mule. Early mules were mostly made of wood. Later, metal parts and gears made them stronger and more efficient. Inventors like Henry Stones and John Kennedy added new features.

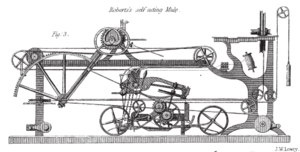

A big step forward came in 1825 with Richard Roberts's "self-acting" or automatic spinning mule. Before this, workers had to help the mule spin a consistent thread. Roberts's invention meant the machine could do much more on its own. It had special parts to unwind yarn, guide it onto the spindle, and change spindle speed automatically. This made spinning much easier and faster.

Mules for Different Yarns

Different areas became known for spinning specific types of yarn. For example, Oldham was known for medium-thickness cotton yarn. Bolton specialized in very fine cotton yarn, which needed a slower, gentler spinning process.

Spinning mules were also adapted for woollen fibers. Wool fibers are different lengths, so they need a special way of being prepared. Woolen mules don't use rollers to stretch the fibers. Instead, they create the stretch by moving the spindles away from the delivery rollers.

"Condenser spinning" was a method developed to use shorter cotton fibers, often waste from other processes. This made soft, coarse yarns for things like blankets. Many condenser mules still exist today, showing their lasting design.

Mules Today

Even though they are old inventions, spinning mules are still used. They are especially popular for spinning woollen and alpaca fibers. Companies around the world, like Bigagli and Cormatex in Italy, still make them.

How a Spinning Mule Works

A spinning mule has a carriage that moves back and forth. This carriage holds the spindles. It travels about 1.5 meters, drawing out and spinning the yarn. On the way back, called "putting up," the new yarn is wound onto the spindle. It forms a cone-shaped package called a "cop."

Fibers, called "rovings," are fed into the mule through rollers. These rollers turn at different speeds. This helps to stretch and thin the roving evenly.

The Steps of Spinning Yarn

- Feeding the Fibers: The raw fibers (rovings) are held on bobbins in a rack called a "creel." They pass through guide wires and between three pairs of rollers.

- Stretching and Thinning: The rollers pull the roving from the bobbin. They stretch it out to the right thickness. The front rollers spin much faster, making the roving even.

- Twisting: As the stretched roving comes out, the spindles spin very fast (6,000-9,000 rotations per minute!). This twists the loose fibers together, forming a strong thread.

- Carriage Movement: While twisting, the spindle carriage moves away from the rollers. This "gain" helps to remove any thick spots in the thread. It makes the yarn smooth and even.

- Stopping and Backing-off: When the carriage reaches its farthest point, the spindles and rollers stop. Then, a process called "backing-off" begins. This unwinds a few turns of yarn from the top of the cop.

- Winding On: The carriage then moves back inwards, towards the rollers. This is "putting up." The spindles wind the newly spun yarn onto the cop. Special wires guide the thread to make a perfect cone shape.

- Repeating the Process: These steps repeat until the cops on each spindle are full. Then, the machine stops, and the full cops are removed. This is called "doffing."

Jobs in the Spinning Mill

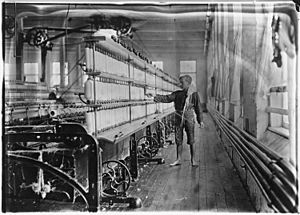

A pair of spinning mules was usually run by a "minder" and two young assistants, called "side piecers" and "little piecers." They worked hard in the mills.

- Creeling: This job involved replacing empty bobbins of roving with new ones. Workers had to do this without stopping the machine.

- Piecing: Sometimes, the yarn would break. Piecers had to quickly repair these broken threads. They would skillfully join the ends together while the mule was moving.

- Doffing: When the cops were full, they needed to be removed. Piecers would quickly lift the full cops off the spindles. Then, the minder would prepare the spindles for a new set of yarn.

- Cleaning: Keeping the machines clean was very important. Short fibers, called "fly," would float in the air and collect on the machine. Workers had to carefully clean the mule to keep it running smoothly.

Key Components

- Drawing rollers: These rollers stretch and thin the fibers.

- Faller and counter faller: Wires that guide the yarn onto the cop.

- Quadrant: A part that helps control the winding of the yarn.

Impact on Society and Work

The spinning mule and other spinning inventions were very important. They helped textile production grow hugely, especially for cotton. Cotton and iron were key industries during the Industrial Revolution. Their growth marked the beginning of this major historical period.

Before, spinning was often done by women and girls at home. But operating the large spinning mules required strength. So, it became a job mostly for men in factories. Weaving, which used to be a man's job at home, was often done by women and girls in the mills.

The spinning mule changed how people worked. It moved jobs from homes to large factories. This led to big economic changes and the growth of cities. Mule spinners were often leaders in forming unions to improve working conditions.

The wool industry also adopted new technology. Woolen mills often used spinning mules. This helped them produce more wool yarn for different types of cloth.

Images for kids

-

Selfactor in Vonwiller & Co., Senftenberg, Austria-Hungary (today Žamberk, Czech Republic)

See also

- Cotton mill

- Textile manufacture during the Industrial Revolution

- Textile manufacturing

- Timeline of clothing and textiles technology