The Lily, Stirling Range facts for kids

Quick facts for kids The Lily |

|

|---|---|

The Lily with Stirling Range

|

|

| Origin | |

| Mill name | The Lily |

| Mill location | Amelup, Western Australia |

| Coordinates | 34°13′28″S 118°12′57″E / 34.224423°S 118.215890°E |

| Year built | 1997 |

| Information | |

| Purpose | Flour mill |

| Type | Ground sail |

| Storeys | 5 |

| No. of sails | 4 |

| Type of sails | Common sails |

| Windshaft | Oak with cast iron poll end |

| Winding | Tailpole and winch |

| No. of pairs of millstones | 1 |

| Size of millstones | 1.4 metres (4 ft 7 in) diameter |

The Lily, also known as The Lily Dutch Windmill, is a tall tower mill found near the towns of Amelup and Borden in Western Australia. It is special because it is one of Australia's few working traditional windmills.

This windmill looks like ones from the 1500s in the Netherlands. It is made of brick and has huge sails, about 24.6 meters (80 feet) wide! A man from the Netherlands, Pleun Hitzert, built it between 1991 and 1997. The Lily is a flour mill that uses large millstones to grind grain. It is the only working windmill of its kind on mainland Australia.

Because it is so unique and close to the beautiful Stirling Range, The Lily is a popular place for tourists to visit.

Contents

How The Lily Windmill Was Designed

The design of The Lily was inspired by several windmills in the Netherlands. It looks a lot like a windmill called De Lelie (which means "The Lily" in Dutch) in a town called Puttershoek.

The Lily's brick tower is round and gets narrower towards the top. It is five stories high. The tower stands over 25 meters (82 feet) tall from its base. The walls are very thick, between 550 mm and 600 mm (about 21 to 23 inches).

The top part of the windmill, called the cap, weighs around 22 tonnes (about 24 tons). This cap can spin all the way around (360 degrees) to make sure the sails always face the wind.

The windmill has Common sails made of strong steel with wood latticework. Workers can attach canvas sails over this wood frame. This helps the windmill catch more wind and make more power.

The Lily's sails are 24.6 meters (about 80 feet) across. When the wind is strong, the sails can spin about 25 times every minute. At this speed, the tips of the sails move faster than 115 kilometers per hour (71 mph)!

The Lily has one set of millstones to make flour. Only the top millstone spins. The bottom stone stays still. The space between the two stones can be changed by hand using ropes. It can also adjust automatically using a special device called a centrifugal governor.

How the Gears Work

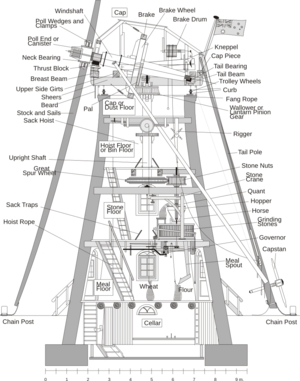

Like many windmills, The Lily has two sets of gears. These gears help transfer power from the sails to the millstones. The first set of gears is between the brake wheel and a part called the wallower. The second set is between the great spur wheel and the stone nut.

These gears are designed so their teeth numbers are coprime. This means they share no common factors other than 1. This helps the gears wear evenly and run smoothly. Together, these gears make the millstone spin about 6.2 times faster than the sails. So, for every one spin of the sails, the top millstone spins about 6.2 times!

The Windmill's Brake System

The Lily has a special brake system called a Flemish brake. This brake uses a rope and a heavy lever. When the lever is lifted, it pulls wooden blocks tightly around the windshaft. The windshaft is the main pole that the sails are attached to.

This brake works very well when the sails are facing the wind. However, it is not as strong if the wind is coming from behind the windmill. To stop the sails from spinning backward, a special part called a 'kneppel' is used.

Windshaft Bearings

The spinning parts of the windmill, like the sails and the windshaft, are held up by two main supports called bearings. The neck bearing holds most of the weight. It is a plain bearing made of solid brass. It is kept smooth with animal fat. The windshaft rests in a small groove in this bearing.

The tail bearing supports the rest of the weight. It also handles any pushing force from the wind.

Building The Lily Windmill

Most of The Lily was built by one person, Pleun Hitzert, between 1991 and 1997. Before he started building, Pleun traveled to the Netherlands. He worked with experienced windmill builders there to learn how to operate and construct a windmill.

Even though the windmill was mostly finished in 1997, it did not have its millstones yet. This was because a restaurant and cafe were using the bottom three floors of the windmill. Later, a new restaurant was built next to the windmill. This allowed the flour milling equipment to be put into The Lily in 2003. After that, The Lily made its first flour, using grains grown on the land around the mill.

Using Recycled Materials

Many recycled materials were used to build The Lily. This is a great example of being environmentally friendly!

- The brick tower was built with handmade bricks. These bricks came from a store in Broomehill that was destroyed by fire in 1991. The bricks were brought to The Lily's site and cleaned by hand.

- The strong wooden beams came from an old jetty in Albany and from old telephone poles. Both of these are made from strong native Australian wood.

- Part of the windmill's tail was made from a sail stock. This came from a windmill in the Netherlands called Landzigt, which was damaged by fire in 1990.

- The wooden cross-arms from old telephone poles were used to make the floors inside the windmill.

How The Lily Operates

One person can operate The Lily, but it is helpful to have a second person when grinding flour. Because of where it is located, The Lily can grind flour most of the year. This is because there are often good winds available.

The millstones can grind many types of wheat. However, The Lily is almost always used to make spelt flour.

| May Edward Chinn |

| Rebecca Cole |

| Alexa Canady |

| Dorothy Lavinia Brown |